Linear Elastic Lateral Buckling (Including Shear Deformation) and Linear Elastic Lateral Torsional Buckling of Composite Beams - an Analytical Engineering Approach- Juniper Publishers

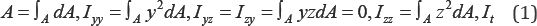

Juniper Publishers- Journal of Civil Engineering

Abstract

This article outlines a concise and complete

versatile novel analytical framework to quickly and effectively assess

lateral shear (knik) and lateral torsional buckling (kip) of composite

beams build of sections with different lengths. The adjective

"composite” includes dissimilar beam cross-sections (beam profiles) and

distinct beam materials. The major aim is to provide engineers with an

accurate, simple but elegant, practically applicable and analytical beam

buckling tool based on advanced solid theoretical propositions or

background. The justification of the analytical theory is supplied by

demonstration of executed numerical tests (i.e. finite element method),

which affirm the validity of the proposed analytical buckling models

adapted to the considered beam buckling cases.

Keywords: Lateral buckling; Lateral torsional buckling; Composite beam; Analytical formulation; Shear deformation; Linear elasticity

Introduction

Buckling means the loss of stability of an

equilibrium configuration of a structure. Elastic buckling is a state at

which the structure loses its stability and large elastic deflections

will start developing rapidly. It is normally associated with the

minimum eigen value of the perfect structure, i.e. often referred to as

classical buckling [1].

In this article attention is confined to linear elastic composite beam

buckling (especially lateral and lateral torsional buckling phenomena).

An abbreviated and lucid literature survey and comprehensive discussion

about lateral and lateral torsional buckling of structural members is

rendered in the dissertation of Raven [2] and the article of Vander Put [3]. It should be highlighted that the adjective "composite” refers to multiple beam cross-sections and beam materials.

Approximate solution methods are frequently

encountered and used in engineering design practice for tackling beam

buckling problems. In particular, summation theorems (i.e. Foppl

Papkovich theorem) are appropriate and advantageous because of their

robustness, accuracy, easiness and algebraic simplicity [4].

It should be kept in mind that there is similarity or analogy with

parallel and serial analytical approaches of spring systems, electric

systems or hydraulic systems (the so-called analogies).

The key goal of this article is to address

respectively formulate an effective analytical tool for reliable

(engineering) estimation or approximation of the linear elastic lateral

shear buckling force and linear elastic lateral torsional buckling

moment of composite beams made of non-overlapping parts based on the

indicated summation theorem and corresponding well-established

structural elastic stability notions [5]. A succinct but detailed exposition of the previous stated matters and issues is offered in the subsequent sections.

Preliminaries and Requisites

Global Cartesian ( components) and local Cartesian (

components) right-handed coordinate systems are used. The former

identify the composite beam orientation, beam location and beam external

loads, while the latter define attached geometrical (shape and size)

properties of the homogenous beam cross-sections. It is henceforth

assumed that the origin of the local coordinate system is located at the

centroid C of the cross-sectional area. In addition, the initial

(undeformed) geometry of the composite beam is a straight line. The

following beams cross sectional quantities (properties) are employed [6].

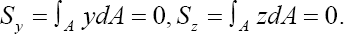

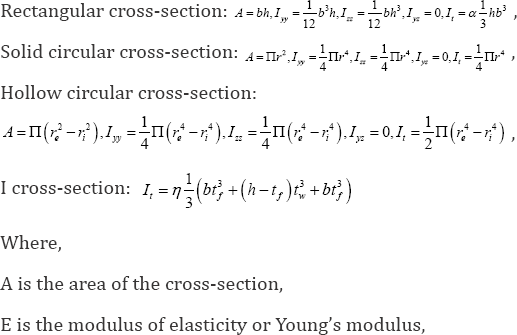

Where,

A is the cross sectional area,

Iyy , Iyz , Izy and Izz are called second moments of area.

Where, It is the torsion constant.

Note 1: The centroid C is defined as that point of an

area A for which the static moments of area are zero when the origin of

the local xyz coordinate system is chosen there, i.e.

The normal centre NC is specified as that point of

the crosssectional area where the resultant of all normal stresses due

to extension has its point of application.

Note 2: In a homogenous (single material) cross-section, the centroid C and normal centre NC coincide.

Note 3: The adopted assumption I yz = Izy = 0 implies that the selected beam cross section has at least two lines of symmetry.

Note 4: I yy and Izz are commonly indicated as the moments of inertia and I yz , I zy are known as the product of inertia. The Equations (1) have been applied to the cross-sections in Figure 1. The results are Shown below.

Linear elastic lateral buckling (including shear deformation) (knik)

Model geometry

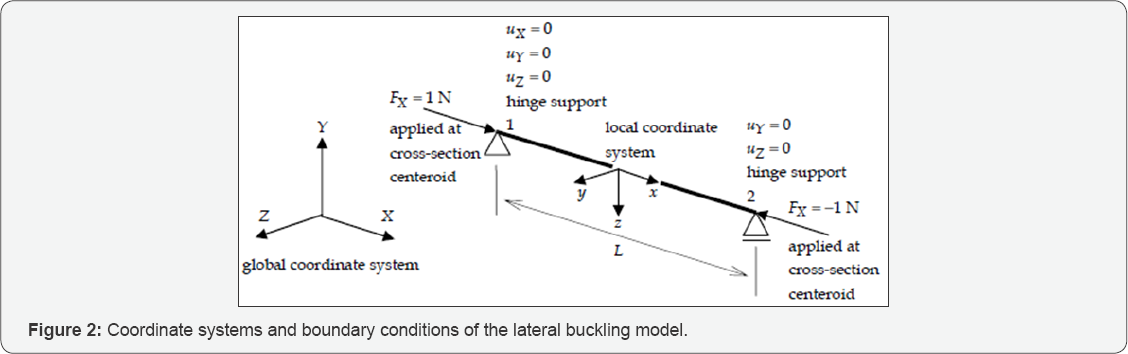

The typical model geometry is depicted in Figure 2. The following mechanical boundary (displacement and load) conditions are implemented (prescribed).

Boundary 1: uX = O, uY = O, uz = O , Fx = l (applied at centroid)

Boundary 2: uY = 0, uZ = 0 , FX = -1 (applied at centroid)

Note 1: A set of balanced forces is obligatory in

order to preserve equilibrium of the composite beam in the analytical

model configuration.

Note 2: The prescribed boundary displacement

constraints prevent rigid body motions (circumvent singularities in the

numerical (finite element) solution process).

Analytical model

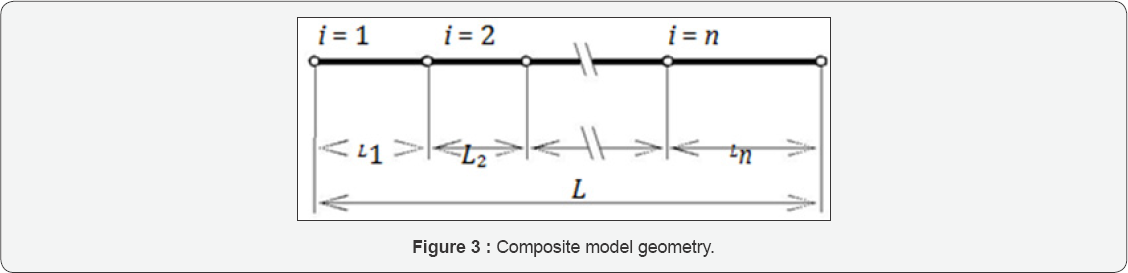

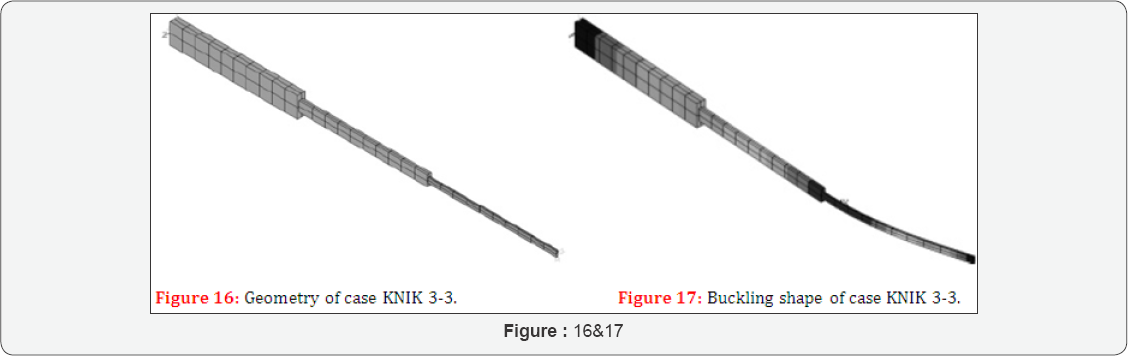

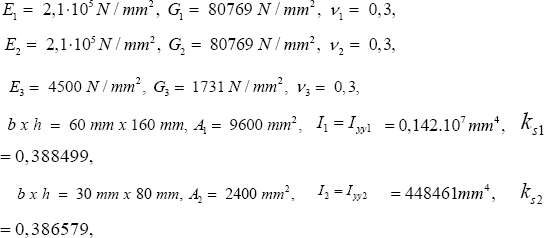

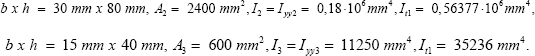

The composite beam with length L is made of segments i with corresponding length Li (Figure 3) and each segment (section) i has the accompanying attributes Young's modulus Ei shear modulus Gi , shear deformation coefficient ksi [7,8] crosssection area Ai and second moment of area

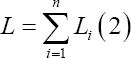

Ii Furthermore, the cross-section of each segment i fulfils the condition Iyyi < Izzi , which implies that Ii=Iyyi Consequently, the following relation holds.

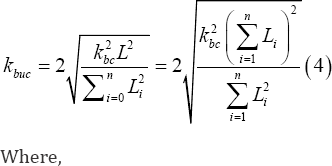

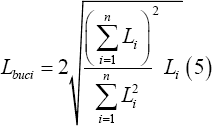

The engineering estimate of the buckling length Ltmci segment i is given by the expression

Lbuci = kbucLi (3)

Where,

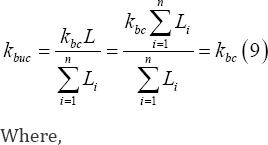

Kbuc Is the buckling length factor, which is identical for each segment in the particular composite beam arrangement.

Kbc Is the buckling length factor of the

composite beam, dependent on the mechanical boundary conditions

(supports). In this specific case of a composite beam with span L and

supported by two hinges at the edges k bc = 1.

It is emphasized that the buckling length of the

composite beam depends only on the boundary conditions and thus not on

cross-sectional properties. Substitution of Equation 4 into Equation 3

produces the following identity.

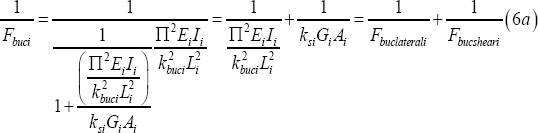

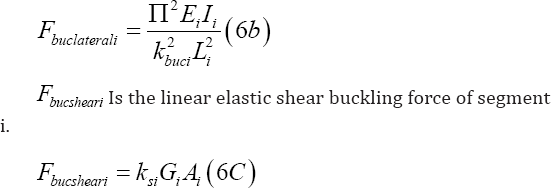

Subsequently, the linear elastic lateral shear buckling force Fbuci of segment i is universally elaborated as shown in Equation 6a. Note that shear deformation is also incorporated, see [5], (Timoshenko 1985).

Fbuc Is the linear elastic lateral shear buckling force of segment i,

Fbuclaterali Is the linear elastic lateral buckling force of segment i,

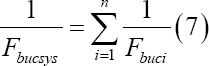

Recalling from literature that the Foppl-Papkovich

theorem (Tarnai 1995) is valid for this case, the following lateral

shear buckling system force equation is stated in general format.

Fbucsys Is the linear elastic lateral shear buckling force of the composite beam (also denoted as system), n Is the total number of considered segments.

The aforementioned formulae devise the complete linear elastic lateral shear buckling analytical model.

Numerical verification (case studies) knik

Three case studies (KNIK 1, KNIK 2 and KNIK 3) are

conducted and concisely presented in order to examine the validity and

soundness of the proposed analytical approach by comparison with

numerical results obtained by the finite element method [9,10].

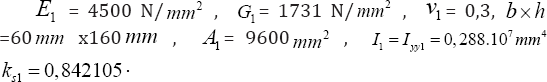

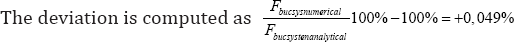

Case study KNIK 1-1

Case KNIK 1-1 considers a wooden beam of one segment (Figure 4).

The properties are L = 3000 mm, L1 = 3000 mm, Kbuc = 1,Kbc = 1,FX=±N,

The obtained results are Fbucsysnumerical =14214N and Fbucsysnumerical = 14221N (Figure 5).

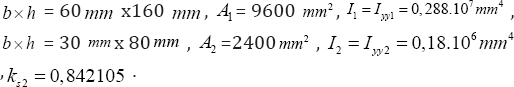

Case study KNIK 1-2

Case KNIK 1-2 considers a composite wooden beam of two segments (Figure 6).

The results are Fbucsysamlytical =I673N, Fbucsysnumerical= I443N

(Figure 7). The deviation is -13, 74 %.

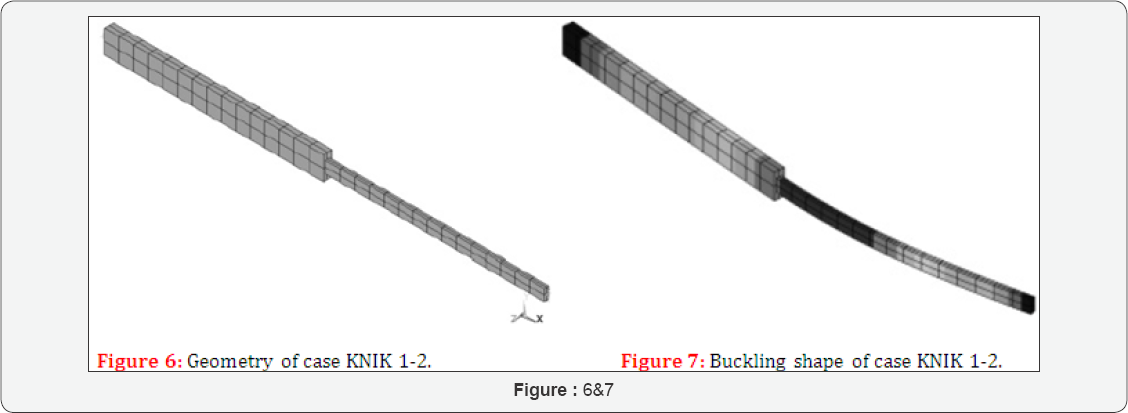

Case study KNIK 1-3

Case KNIK 1-3 considers a composite wooden beam of three segments (Figure 8).

The properties are L = 3000 mm, L1 = 1000 mm, L2 = 1000 mm, L3 = 1000 mm,

The results are Fbucsysanalytical =156 N and Fbucsysnumerical = 161 N

(Figure 9). The deviation is +3, 11 %.

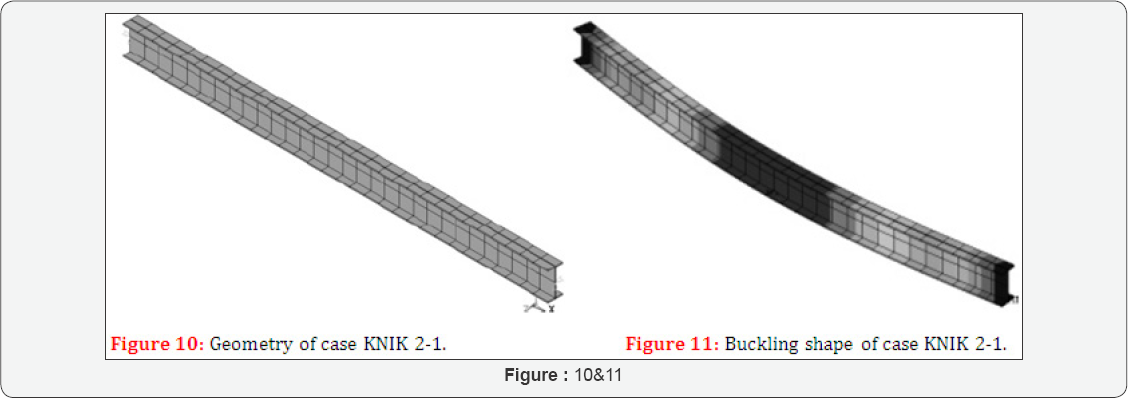

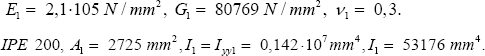

Case Study KNIK 2-1

Case KNIK 2-1 considers a steel beam of one segment (Figure 10).

The properties are L = 3000 mm, L1 = 3000 mm, Kbuc = 1,Kbc = 1,FX=±N,

The obtained results are Fbucsysnumerical =328263N and Fbucsysnumerical = 326493N (Figure 11).

The deviation is -0,539 %.

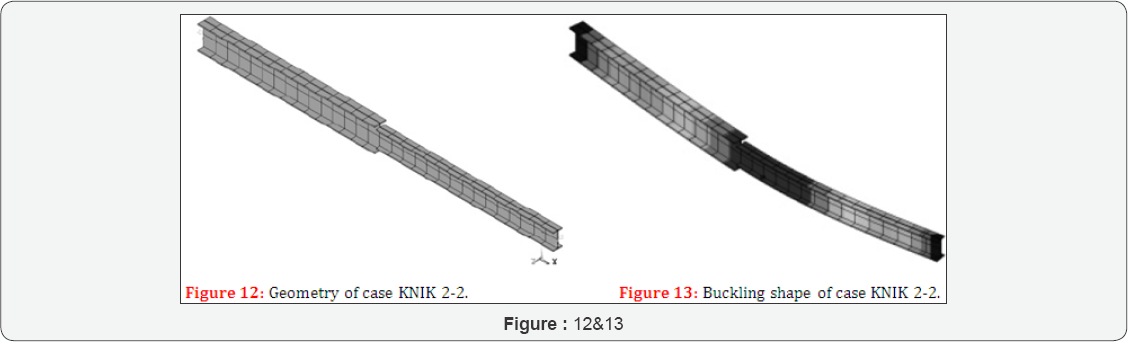

Case Study KNIK 2-2

Case KNIK 2-2 considers a composite steel beam of two segments (Figure 12).

The properties are L = 3000 mm, L1 = 1500 mm, L2 = 1500 mm, kbuc = 2, kbC = 1, FX = ±1 N,

The results are Fbucsysnumerical = 157757N and Fbucsysnumerical=

147745N (Figure 13) the deviation is -6,346%.

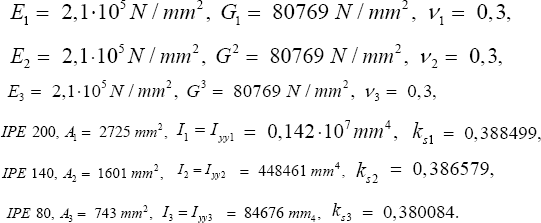

Case Study KNIK 2-3

Case KNIK 2-3 considers a composite steel beam of 3 segments (Figure 14).

The properties are L = 3000 mm, L1 = 1000 mm, L2 = 1000 mm, L3 = 1000 mm,

The results are Fbucsysanalytical = 47024N and fbucsysnumerical= 48983N (Figure 15). The deviation is +4,165 %.

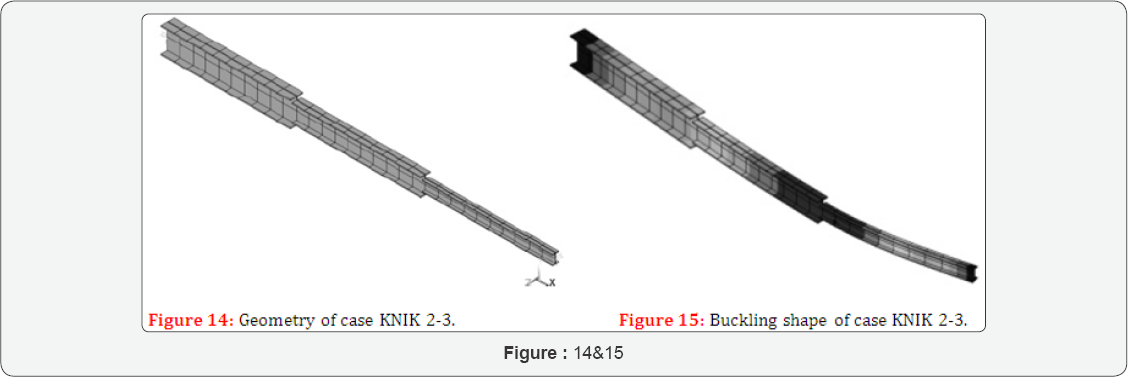

Case Study KNIK 3-3

Case KNIK 3-3 considers a composite steel-wood beam of three segments (Figure 16).

The properties are L = 3000 mm, L1 = 1000 mm, L2 = 1000mm,L3 = 1000 mm,

The results are = 166 N and = 171 N (Figure 17). The deviation is +3,012 %.

Linear elastic lateral torsional buckling (kip)

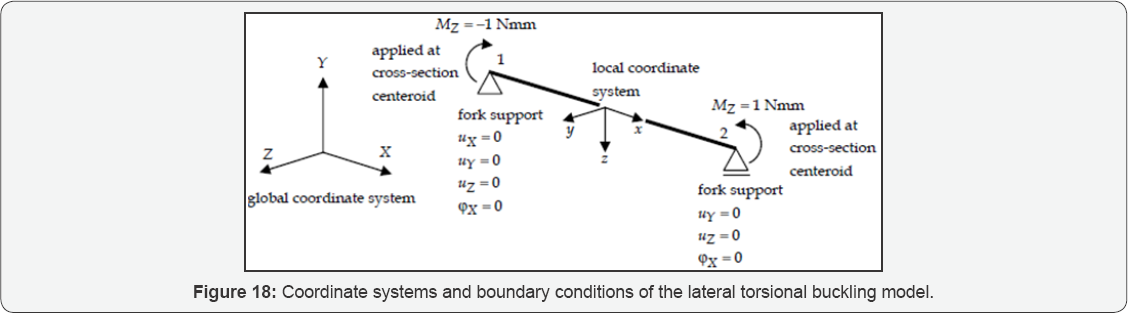

Model geometry

The governing model geometry is shown in Figure 18. The following mechanical boundary (displacement and load) conditions are implemented (prescribed).

Boundary 1: ux = 0 uy = 0 uz = 0 , φx = 0, Mz = -1 (applied at centroid).

Boundary 2: uy = 0 uz = 0 , φx = 0,

Mz = +1 (applied at centroid).

Analytical model

The model for lateral torsional buckling is mostly

identical to the models for lateral buckling (Section 7.2). Not used in

lateral torsional buckling is the shear deformation coefficient ks1. Extra is the is the torsional constant Iti,.

The cross-sectional warping stiffness of segment i is assumed to be

negligible. The engineering estimate of the buckling length Lbuci of segment i is

Lbuci = kbucLi (8)

Where,

kbuc Is the buckling length factor. Which, is the same for each segment in the specific composite beam configuration

kbuc Is the buckling length factor

of the composite beam, dependent on the mechanical boundary conditions

(support). In this specific case of a composite beam with span L and

supported by two forks at the edges:

kbc = 1

It is underlined that the buckling length of the

composite beam is only dependent on the boundary conditions and hence

not on cross-sectional properties. Substitution of Equation 9 in

Equation 8 produces the following identity.

Lbuci = kbucLi (10)

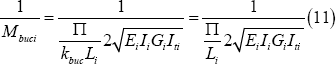

Taking into account the previous settled propositions, the linear elastic lateral torsional buckling moment Mbuci of segment i is

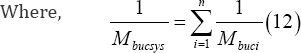

The Föppl-Papkovich theorem (Tarnai 1995) is apt for

this case. The following lateral torsional buckling system moment

equation is written in universal layout.

Mbucsys Is the linear elastic lateral torsional buckling moment of the composite beam (also symbolized as system).

n is the total number of segments.

The aforesaid procedure details the full linear elastic lateral torsional buckling analytical model.

Numerical verification (case studies) kip

Three case studies (KIP 1, KIP 2 and KIP 3) are

consecutively undertaken and compendiously offered in order to inspect

the legality or reliability of the analytical approach by judgment of

numerical results.

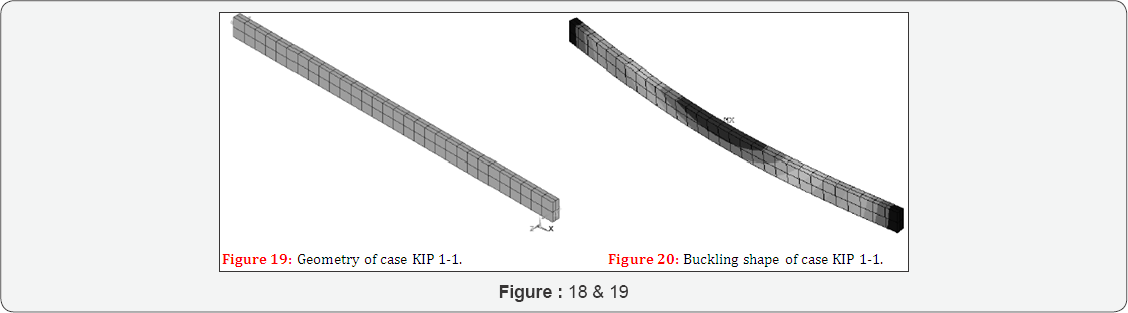

Case study KIP 1-1

Case KIP 1-1 considers a wooden beam of one segment (Figure 19).

The properties are L = 3000 mm, L1 = 3000 mm, kbuc = 1, kbc =±1 Nmm,

The results are M buaysanaiytcai = 0,149-108 Nmm and M buaysanaiytcai= 0,149-108 Nmm (Figure 20).

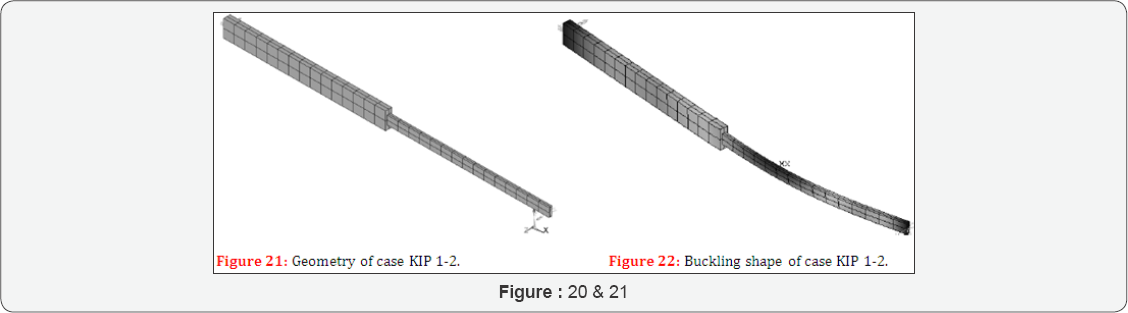

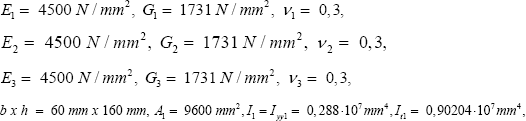

Case study KIP 1-2

Case KIP 1-2 considers a composite wooden beam of two segments (Figure 21).

The properties are L = 3000 mm, L1 = 1500 mm, L2 = 1500 mm, kbuc = 1, kbc = 1, MZ = ±1 Nmm,

The results are M buaysanaiytcai = 0,175-107NmmM buaysanaiytcai and =0,176-107Nmm (Figure 22).

The deviation is +0, 57%.

Case study KIP 1-3

Case KIP 2-3 considers a composite wooden beam of three segments (Figure 23).

The properties are L = 3000 mm, L1 = 1000 mm, L2 = 1000 mm, L3 = 1000 mm, kbuc =1, kbc = 1, Mz = ±1 Nmm,

The results are M bucsysanalytical = 163701 Nmm and Mbucsysnumerical = 164801 Nmm (Figure 24).

The deviation is +0, 67 %.

Case study KIP 2-1

Case KIP 2-1 considers a steel beam of one segment (Figure

25).

The properties are L = 3000 mm, L1 = 3000 mm, kbuc = 1, kbc = 1, —z = ±1 Nmm,

The obtained results are M bucsysanalytical = 37, 48-106 Nmm and M bucsysanalytical = 37,5-106 Nmm (Figure 26).

The deviation is +0,053 %.

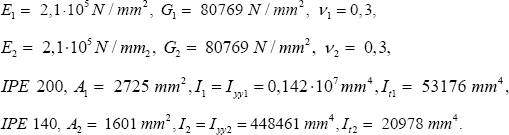

Case study KIP 2-2

Case KIP 2-2 considers a composite steel beam of two segments (Figure 27).

The properties are L = 3000 mm, L1 = 1500 mm, L2 = 1500 mm, kbuc = 1, kbc = 1, MZ = ±1 Nmm,

The results are M bucsysanalytical = 19, 55-106 Nmm and M bucsysanalytical= 19, 2106 Nmm (Figure 28).

The deviation is -1, 79 %.

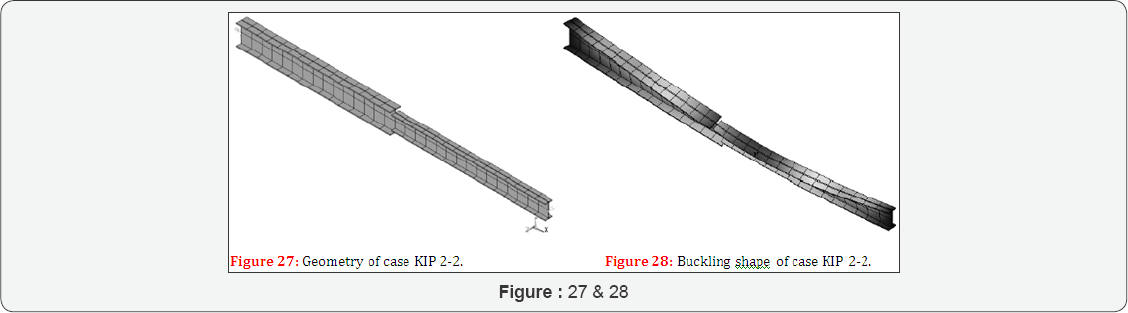

Case study KIP 2-3

Case KIP 2-3 considers a composite steel beam of three segments (Figure 29).

The properties are L = 3000 mm, L1 = 1000 mm, L2 = 1000 mm, L3 = 1000 mm, kbuc = 1, Kc = 1, MZ = ±1 Nmm,

The results are = 6, 91-106 Nmm are = 6, 68-106 Nmm (Figure 30).

The deviation is -3,328 %.

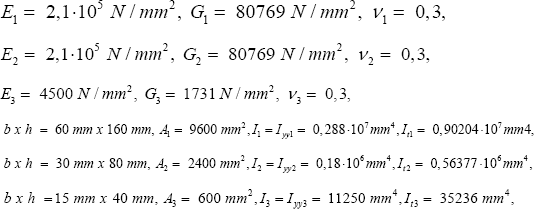

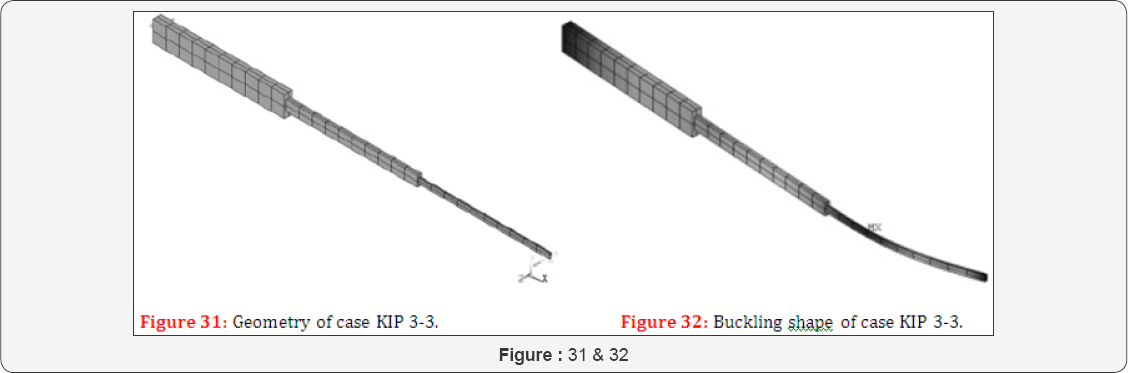

Case study KIP 3-3

Case KIP 3-3 considers a composite steel-wood beam of three segments (Figure 31).

The properties are L = 3000 mm, L1 = 1000 mm, L2 = 1000 mm, L3 = 1000 mm, kbuc = 1,

kbuc = 1, MZ = ±1 Nmm,

The results are = 174324 Nmm and = 175756 Nmm (Figure

32).

The deviation is +0,821 %.

Conclusion

Numerical evaluation confirms the correctness of the

presented linear elastic lateral shear and lateral torsional buckling

analytical models. The deviations between the analytical and numerical

approach are rather small and reveal clearly the ability to yield

realistic outcomes. The supplied analytical linear elastic buckling

models produce accurate and reliable values, which can be classified as

suitable for engineering design purposes. Needless to cite that the

analytical approach should always be cautiously applied and the results

ought to be methodically checked by the responsible structural engineer.

A salient observation is that the presented tactic could also be

invoked for linear elastic buckling assessment of castellated and

cellular (steel) beams. However, this assertion has not yet been

verified and is thus speculative. Insertion of plasticity is

straightforward however treatment of this topic is beyond the scope of

this article.

For More Open Access Journals Please Click on: Juniper Publishers

Fore More Articles Please Visit: Civil Engineering Research Journal

Fore More Articles Please Visit: Civil Engineering Research Journal

Comments

Post a Comment