Substantiation of the Way of Modernization of Shunting Diesel Locomotives- Juniper Publishers

Civil Engineering Research Journal- Juniper Publishers

Introduction

The efficient consumption of fuel and energy resources is one of the most important challenges facing the economies of developed countries. The railway transport sector is one of the largest power consumers in the national economy. Nowadays, energy efficiency is the most important factor in increasing the competitiveness of railways on the national and international market for transport services [1]. The major part of the fuel and energy resources of the railway transport is consumed for the traction of trains. Today it is 82% of total electrical energy consumption and 90% of diesel fuel consumption. In this connection the energy saving concentrates primarily on the main type of operation – the transportation process. From this point of view, the issue of increasing energy efficiency is very relevant for railways and requires further research. The practice shows that today more than 40% of all transportation operations on the railway are carried out by shunting diesel locomotives, therefore the modernization of such locomotives is the most expedient [2].

The main requirements for the new generation of shunting locomotives of this power are:

A. Maximum use of energy to achieve traction power, minimization of energy consumption for auxiliary needs and costs for the purchase of fuel and lubricants;

B. Minimizing labor costs throughout the lifecycle, including all types of maintenance and repair costs;

C. Environmental friendliness and high ergonomics that conform to current and prospective national and global standards.

In order to meet the above requirements, global locomotive manufacturers tend to introduce hybrid power transmissions in railway transport. However, most shunting diesel locomotives operated worldwide on the railways have a transmission without energy storage. According to statistics, more than 40% of shunting operations are locomotive downtime with the engine running and 10-15% of the time are movements without wagons [3]. The distribution of the operation modes of a shunting locomotive is shown in Figure 1.

Figure 1 above shows that the use of powerful shunting diesel locomotives is economically impractical, since the use of locomotives with partial loading leads to extra fuel consumption. Therefore, the transition to a hybrid system with a low-power diesel generator unit is the most promising trend today. Hybrid locomotives (or vehicles with an integrated power unit) hold an intermediate position between a conventional locomotive (with an internal combustion engine) and an electric locomotive (powered by overhead contact wires) [4]. The hybrid consists of two or more energy sources: a diesel generator of the unit, an accumulator, a buffer storage device, etc.

The analysis of alternatives to the new generation drive has shown that a competitive vehicle can actually be built using an integrated power plant. Such a plant consists of an internal combustion engine, a generator, an electric traction drive and an energy storage device, and advantageously combines the positive properties of each unit. Therefore, the priority today is an integrated plant with a thermal engine. With such a solution, fuel consumption is reduced by at least 40%, since most of the shunting operation will be powered by a traction battery while ensuring high environmental friendliness of the locomotive [5].

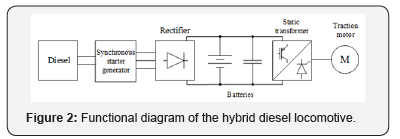

Figure 2 shows a functional diagram of the hybrid diesel locomotive comprising a diesel engine, a synchronous starter generator, a rectifier, an energy storage device (rechargeable battery, ionizers), a static converter and a traction engine, which can be either a DC or an AC engine.

Conclusion

The use of energy storage devices in the system eliminates the need for diesel engine speed control systems in favor of traction engine control systems. In the diesel locomotive shown above, the diesel engine is only started in driving modes with heavy trains and runs with rated rpm at rated fuel consumption.

For more open access journals, please click on: JuniperPublishers

For more civil Engineering articles, please click on Civil Engineering Research Journal

https://juniperpublishers.com/cerj/CERJ.MS.ID.555714.php

Comments

Post a Comment