Organizational Safety Risk Analysis in Aviation Industry; An STP a Based Framework- Juniper Publishers

Juniper Publishers- Journal of Civil Engineering

Abstract

ICAO recent manuals for both State Safety Policy

(SSP) and Safety Management System (SMS) explicitly concentrate on the

organizational roots of accidents. The Safety Risk Management (SRM)

system, as the core component of both SSP and SMS, consequently are

expected to manage the organizational safety risk. In view of that, this

paper present a new risk analysis framework that can be feasible to

apply as the analyzing logic of the formal SRM; especially, in the start

line of the risk management process. For this reason, the framework is

founded on the System Theoretic Process Analysis (STPA) to cope with the

sociotechnical feature of aviation organization. To apply STPA as the

base of the framework, a customized "Feedback Control Loop” is applied

to model organizational control mechanisms and extracts their hidden

hazards. Furthermore, an innovative concept and procedure are introduced

for "Hazard Activation Likelihood” estimation and

"HazardConsequences”analysis.

Keywords: STPA; STAMP; SMS; Safety risk analysis; Aviation safety

Abbreviations:

State Safety Policy; SMS: Safety Management System; SRM: Safety Risk

Management; STPA: System Theoretic Process Analysis; QC: Quality

Control; R&T: Research & Technology HACS: Activation Consequence

Severity; HAL: Hazard Activation Likelihood; OSCSC: Organizational

Safety Control Structure's Competency

Introduction

Based on Annex 19 of Convention on International

Civil Aviation,each State shall establish an SSP for the management of

safety in the State, in order to achieve an acceptablelevel of safety

performance in civil aviation [1]. Each State also shall require all service providers to implement and maintain an SMS [1].

Since, Safety Risk Management is an important component of both SSP and

SMS, not only States but also all aviation service providers must

implement an appropriate safety risk management system to support their

decision making process.Clearly, the aim of the SMS (and SSP) Safety

Risk Managementprocess is to identify and handle all significant

influences that may impact on aviation safety, when determining

contributing factors for the analysis of consequences of a hazard and

deciding on risk mitigation measures.

On the other hand, the pivotal concept of SMS

and,consequently, Safety Risk Management systemof wich is concentration

on organizational roots of safety hazards and accidents. In fact, in

contrast to conventional safety approach,which centers on the technical

aspect of the system, the SMS changesthe focus to organizational

aspects. This focus changing, of course, is appropriate because many

studies have proven that management short comings and organizational

aspects are major factors in the occurrence of accidents in complex

systems such as aviation industry [2-4].

Based on SMS main concept, which roots in

epidemiological accident models, accident's initiating mechanisms do not

derive from technical components; rather, originate in organisational

and cultural mechanisms, especially the decision-making processes. All

aviation service providers thus must tackle these issues throughan

appropriate Risk Management system that is equipped with proper

techniques to grasp and handle this kind of safety risks.

The main problem is that the safety risks of aviation

organizations - as complex and sociotechnical systems-are not

extractable only by Conventional Risk Analysis Models (like FMEA, FTA,

and other reliability based approaches); especially their complex

organizational-based risks. In fact, traditional safety analysis tools,

which developed based on pure technical system [5]

, are not able to cope with the complexity of sociotechnical systems.

Aviation organization thus should apply systemic approach, as

recommended by ICAO Doc. 9859, to address their safety issues.

According to the above, the main objective of this

paper isthe proposingof an organizational-based systemic risk

analysisapproach, as the central part of the Risk Management System, for

preparing an appropriate framework to initiate Safety Risk Management

process in aviation organizations.

Accordingly, a clear procedure for organizational

hazards identification, as well as a clear logic for hazard probability/

severity analysis is presented in this paper by the following order: at

first, the main concepts of Safety Risk Management are reviewed. Then,

the principles of STAMP and STPA (as the base models for the presented

framework) are expressed. After that, our specific organizational risk

analysis framework is described. Afterward, the practicality of the

framework is proved by a case study, and finally, the summary and

discussion parts are presented.

Main concepts and Based model

Risk management system and the scope of the work

The field of risk management is faced with

difficulties in defining and agreeing on principles. Risks are dealt

with differently across different countries, industries, and sectors [6].

Although terms, definitions, and interpretations are as varied as the

number of sources providing them, we stand our work based on this

definition: The Safety Risk Management system is the overall integrated

process consisting of two essential interrelated and overlapping, but

conceptually distinct components - Risk Assessment and Risk Management1 [6].

Mullai summarize the fundamental parts of this definition as following [6]:

"Risk assessment" combines both Risk Analysis and

Risk Evaluation, providing practically useful and logically structured

inputs and perspectives about risks for "Risk Management" (the decision-

making process, development of policies, strategies, and measures).

"Risk analysis" is a scientific process in which, by

applying a wide range of methods, techniques and tools, risks are

identified, estimated, and presented in qualitative and/or quantitative

terms. "Risk evaluation" is the process of comparing estimated risks

with established risk evaluation criteria (e.g. criteria based on the

best available technology, legal requirements, practices, processes, or

achievements) in order to determine the level or significance of risks

and provide recommendations for the decision-makers at various levels.

Based on the main purpose of this paper, our work is

limited to "Risk Analysis" part of risk management system, which

includes Hazard Identification and Risk Estimation. The "Risk

Estimation" component itself comprises Likelihood Estimation, Consequent

Analysis, and Risk Presentation (Present estimated risks based on a

specific format such as number, index, color, etc.)

Based model for organizational-based hazard identification

Traditional models of hazard identification, which

are summarized as Chain-of-failure-event models, have major inability to

handle organizational factors, managerial (social and cultural) roots,

and the systemic causes in sociotechnical accidents [7].

In contrast, Systemic approach to technical and organizational safety -

which developed by group of researchers, including Rasmussen, Woods,

Dekker, Leveson, and Hollnagel, most of whom come from system

engineering and human factors backgrounds - is able to appropriately

tackle the safety issues of the complex sociotechnical systems [2,8].

The systemic view of safety, and its related

techniques, considers accident as the consequence of Hierarchical Safety

Control Structures deficiency; therefore, tries to analyze the root

cause of gradual deficiencies among the hierarchical control structures

by applying holistic and systemic approaches [9].

Related studies have shown that the systemic approaches could be

effective tools to model organizational interaction and analyze accident

causation within system's hierarchical control structures [10].

While several researchers have proposed the systems

approaches to safety, Leveson's STAMP (Systems-Theoretic Accident

Modeling and Processes) approach has an outstanding superiority and

provides a perfect view of the organizational aspects of safety [11].

Systems-theoretic accident modellingand processes (STAMP):

STAMP was created to capture more types of accident causal factors

including social and organizational structures, new kinds of human

error, design and requirements flaws, and dysfunctional interactions

among non-failed components. Rather than treating safety as a failure

problem or simplifying accidents to a linear chain of events, STAMP

treats safety as a hierarchical control problem in which accidents arise

from complex dynamic processes that may operate concurrently and

interact to create unsafe situations [12].

STAMP taking into account all facets relating the

social to the technical aspects, and like the general systems approach

to engineering, focuses on the system as a whole, not on the parts or

components individually. It assumes that some properties of systems can

be treated adequately only in their entirety. These "system properties"

derive from the relationships between parts of systems: how the parts

interact and fit together. Concentrating on the analysis and design of

the whole as distinct from the components or parts provides an important

advantage for STAMP to study safety of the complex systems.

STAMP considers systems as interrelated components

that are kept in a state of dynamic equilibrium by feedback loops of

information and control [13].

According to this model, accident (systemic accident) could be the

result of the dysfunctional performance of adaptation feedback control

loop; the controls that may be managerial, organizational, physical,

operational, or manufactural. In this view, accidents can be

characterized as the resulting from an adaptive feedback function that

fails to maintain safety, when performance changes over time to meet a

complex and changing set of goals and values [7].

STAMP practicality has been demonstrated by applying

it to a number of real and complex systems, including a risk analysis of

the organizational structure of the Space Shuttle program after the

Columbia loss [14]; tradeoffs among safety, budget, schedule, and performance risks in the new NASA space exploration mission organization [9]; unmanned spacecraft design [15];

a safety assessment of the new U.S. missile defense system; safety in

the pharmaceutical industry; and safety of outpatient surgery at

Boston's Beth Israel Deaconess Hospital [16], and many other recent studies.

System theoretic process analysis (STPA):

Leveson restated that STAMP considers a set of new causality factors for

accidents that none of former risk analysis methods can analyze them [13].

She, consequently, developed the STPA method in order to be possible to

consider all accident's important aspects and features in process of

hazard analysis. Experiences indicate that Leveson has gone the right

way because it is admitted by researchers that STPA is significantly

more powerful than failure-based techniques in the ability to capture a

wider array of hazardous behaviors, including organizational aspects,

requirements flaws, design errors, complex human behavior, and component

failures. [17]

In respect to STAMP logic, STPA considers accident as

result of inadequate control. In fact, STPA accepts that a set of

control components and particular interactions have evolved or embedded

in system as safety hierarchical control structure; these components and

their interrelation mechanisms - in the form of feedback control loop -

continually monitor and constrain, by use of Control Actions, the

system's behavior to control its dynamicity. In this described

condition, accidents occur if a specific control mechanism for

restriction of a particular system hazardous behavior doesn't exist or

existing control mechanism doesn't able to enforce an expected Control

Action.

Basically, STPA concentrates on high-level risks and system's safety constraints to:

o Perform responsibility gap analysis by assessing control components responsibilities and analyzing the probable gap;

o Cognize systemic hazardous behaviors by identifying unsafe Control Actions;

o Accommodate high-level safety constraints into

lower levels to control hazardous behaviors; and propose new control

mechanisms for enforcement of the new constraints if needed.

o Identify root causes of system's hazardous behavior

by analyzing the components of Feedback Control Loop to correct the

loops' mechanism.

Although STPA is relatively new compared to

traditional methods, it has been demonstrated successfully on a wide

range of systems including aviation [18] , spacecraft [19], missile defense systems [20], aviation maintenance [21], civil infrastructure [22], and others.

Additionally, while STPA is a hazard analysis

technique developed for analysis and design of system safety

architectures, its basis in control theory and system engineering lends

to the application of it to social, and non-safety related control and

early risk management. Some of the most important samples of this

extension include cyber security [23] , business systems and financial operations [24], and the impact of political systems on failures of public infrastructure [25].

The New Approach for Organizational-based Safety Risk Analysis

Why not the original form of STPA

Although the presented risk analysis framework mainly

stands on the principles of STPA, this method is not applicable to

initiate a formal risk management process in aviation organizations in

its original form. This is firstly because the hazard identification

process of STPA is fairly complex, detailed and comprehensive.

Therefore, it is not appropriate for initiating a formal risk analysis

process.

Secondly, and the most important, for the lack of

"Risk Estimation Procedure" organizations are not able to use STPA as

their formal Risk Analysis Framework; particularly at the initiating

phase. In fact, although the STPA - and other STAMP- based methods -have

been had invaluable achievement regarding revealing the hidden causes

of the catastrophic accident in the complex sociotechnical system, they

do not propose a procedure to estimate the risk of the identified

hazards. These model, therefore, are not applicable as a formal risk

analysis framework [26].

Certainly, the reluctance toward developing a risk

estimation procedure - exactly quantification of probability and

severity - in STAMP-based methods derives from both essence of the

complex systems and the superior awareness of the models' architects

toward the effect of the system complexity on cause- effect modeling. In

fact, while modeling the cause and effect chains between initiating

mechanism and the final consequence is the prerequisite step of risk

quantification, anticipating and modeling the interrelation between

system's components as well as the relation between system behavior (as a

consequence) and its components performance is impossible in the

complex sociotechnical system. In truth, after finding a specific

hazardous performance of a system component, it is impossible to trace

all chains of events that may start from that specific hazardous

performance and be over to a probable accident scenario. As a result,

the probability estimation is impossible. On the other hand, since the

specific consequence of the hazardous system's component performance is

not clear, the severity of associated consequence is not estimable too.

Nevertheless, if there were enough historical data

for making a relation between the "presence of specific hazards" and

"occurrence of a particular mishap", the risk estimation would be

applicable, even without modeling the cause-effect relations. Enough

pertinent data, however, is not available in such complex systems,

especially for organizational malfunction mechanisms.

Some researchers have proven that there is very

little scientific data validating probabilistic risk assessment or

evaluating the methods for calculating it, particularly for complex

engineered systems [7, 27,28]. Accordingly, there have been some studies

comparing probabilistic risk assessments performed by different groups

on the same system where the results indicated large differences in the

frequencies calculated for the event [27,29].

In this regard, Leveson mentioned that many major, well-known accidents

have occurred in systems where the probability of an accident was

previously calculated to be 10-9 or less, including

Chernobyl, Fukushima, Texas City, Deep Water Horizon, the Therac-25,

Challenger, and Columbia, to name but a few [7].

Follensbeealso cites five large transport aircraft accidents and one

near accident where the calculated probabilities were 10-9 or less.

Still, Leveson is making a new innovative solution to

overcome the problem of "likelihood" in her remarkable hazard analysis

approach. Her solution is based on the "Leading Indicators" that can be

identified based on the assumptions underlying safety engineering

practices and on the vulnerability of those assumptions rather than on

likelihood of loss events. In fact, Instead of trying to predict the

likelihood that an event will occur or an assumption will fail, the

similar but different concept of vulnerability can be used.

Vulnerability in the world of assumption-based planning involves

assessing whether an assumption could plausibly fail during the lifetime

of the system, not the specific probability of that happening [7].

The difference is that instead of trying to assign a

numerical likelihood estimate or one of a set of poorly defined

categories, only two categories, possible and impossible, are used. That

is, if the likelihood is not zero, then the assumption needs to be

considered for inclusion in the leading indicators program.

Despite the solution that is being developed by

Leveson, we still need a clear "Risk Estimation Procedure" to make it

feasible to apply STPA, and its superior hazard identification logic,

for organizational risk analysis; even if the estimated risk aren't

mathematically meaningful and accurate. In fact, when we focus on

Organizational Dysfunctional Mechanisms as the hazards, the exact

estimation of failure probability is good-for- nothing. In contrast, we

just need a clear Prioritizing Logic to lead the corrective action plan

in its right way. So we believe that a proper Risk Estimation Procedure

can still be combined with STPA without trapping us on probability

estimation obstacles and problems.

Accordingly, a desirable STPA-based organizational

risk analysis frameworkfor aviation safety management, which be able to

extract the target hazards and prioritize the corrective actions, mustbe

made of following parts:

o A framework to model the system's organizational

safety control loops ( As the initial step of the Hazard Identification

Process)

o A clear procedure to extract significant organizational hazards (As the main step of the Hazard Identification Process)

o A framework to estimate Likelihood and Consequence of the hazards; and

o A proper guideline for advanced analysis

In the following, these necessary parts are described

to make a partially simple and clear framework for an STPA-based

organizational risk analysis procedure.

Hazard Identification

Safety control loops; the roots of the hazards:

Based on the STAMP and STPA main concept, accidents occur if Safety

Control Structure, which made of a series of inter-connected feedback

control loops, cannot be able to control the system behavior. In fact,

the feedback control loops deficiency is the main cause of system’s

uncontrolled behaviors. As the important result, Safety Feedback Control

Loops are the "source" of the hazards.

When we add SMS pivotal concepts to the previous

argument, the Deficient Safety-Related Organizational Mechanisms are the

hidden hazards that we should extract them to control the system's

risk. As the bottom line, when we run the STPA-based organizational risk

analysis procedure, we should focus on safety-related organizational

mechanisms' deficiencies, which are active among Safety Feedback Control

Loops, in the hazard identification step.

In the following, the concept of Feedback Control Loop, as the source of hazards, is reviewed.

Feedback control loop and process model: Based on the control theory, the four following conditions are required inorder to control a processby a control component [13]:

o Goal Condition: The controller must have a goal or goals.

o Action Condition (or controllability condition):

The controller must be able to affect the state of the system. In

engineering, Control Actions are implemented by actuators.

o Model Condition: The controller must be (or contain) a model of the system.

o Observability Condition: The controller must be

able to as certain the state of the system. In engineering terminology,

observation of the state of the system is provided by sensors.

These conditions are the requirements of the

fundamental loop in the control theory that have been named as "Feedback

Control Loop". In control theory, open systems are viewed

asinterrelated components that are kept in a state of dynamic

equilibrium by feedback loops of information (communication) and control

mechanisms. These loops also have a paramount position in STAMP and

STPA method, as the models that were based on the control theory,

because STAMP and STPA consider accidents as the control problems.

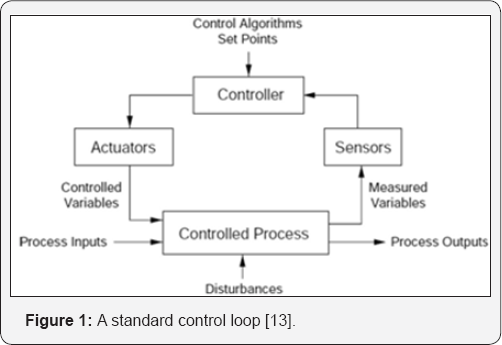

Figure 1

displays a typical technical control loop for controlling information

about (observes) the process state from measured variables (feedback)

and uses this information to initiate action by manipulating controlled

variables to keep the process operating with inpredefined limits or

setpoints (the goal) despite disturbances to the process.

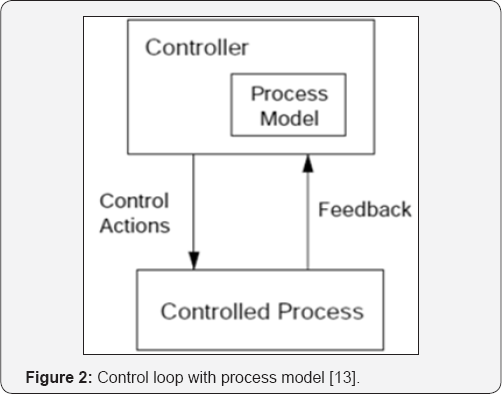

In this loop, Process Models have a significant role,

because automate (or human) controllers must be able to simulate the

under controlled process in their logic (or mind) for enforcement of

Control Action to keep the process operation within predefined limits.

Every controller, in fact, must contain a model of the processes that

are being controlled. Accidents happen when the controller's Process

Model does not match the system that is being controlled and,

consequently, the controller issues inappropriate commands [13]. Figure 2 shows a general control loop

Organizational components need the same tools to do

their control duties; however, the type of the loop's components and

variables may be somewhat different. For example, organizational

variables and goals are not as clear as the technical variables.

Furthermore, feedback and actuator channels in organizational control

loops are forms and formal requests or reports; instead of signals or

other technical tools that usually are used in technical loops [21].

Moreover, Control Processes in organizational control

loops are not a mathematical function or logical algorithms. Actually,

organizational loops' control processes almost are a form of unclear

decision-making models that exist in decision makers' mind; the persons

who are engaging in decision making in the different level of the

organizational hierarchy. In fact, they may be either a technician, for

technical decision-making, or a top or middle manager for strategic or

executive decisions.

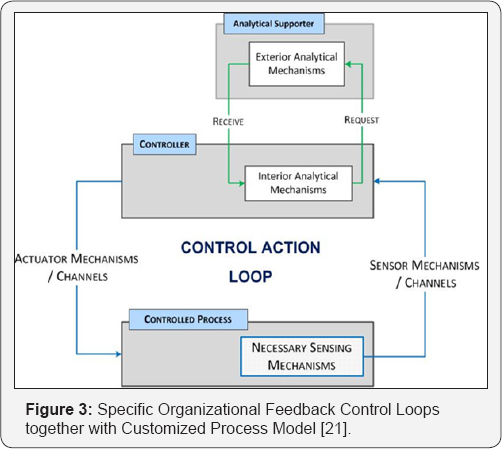

Organizational feedback control loop: In order

to apply STPA for initiating organizational hazard analysis, as the

main reason of this paper, it is needed to use a specific version of the

feedback control loop that was exclusively developed for deficiency

analysis of organizational safety control mechanisms. Figure 3 presents thisspecific Organizational Feedback Control Loop to gether with its customized Process Model [21]. Based on Figure 3, five requirements shall be met to accurately enforce the Control Actions by organizational control components:

a. A Necessary Sensing Mechanism must be active in

the process under control to collect, process, and prepare accurate

information for the control component. This mechanism is a type of

organizational processes that may be managed by either main control

component of the loop or other organizational components.

b. A reliable Sensor Mechanism (or channels) must be

active for delivering the prepared information to the control component.

This mechanism is also a type of organizational communication channel.

c. An Analytical Mechanism must be active for accurate processing of received information to determine appropriate

Control Action. This mechanism is also a type of

organizational processes. While Interior Analytical Mechanism is applied

by the control component of the loop, Exterior Analytical Mechanism is

applied via other organizational components (in a situation that

exterior analyzing is needed).

d. A reliable Request-Receive Mechanism must be

active to receive necessary information from other components (in a

situation that exterior analyzing is needed). This mechanism also is a

type of organizational process, which prepares appropriate context for

information exchange between Interior and Exterior Analytical

Mechanisms.

e. A reliable Actuator Mechanism (or channels) must

be active to enforce the Control Action to under control process. This

mechanism is also a type of organizational communication channel.

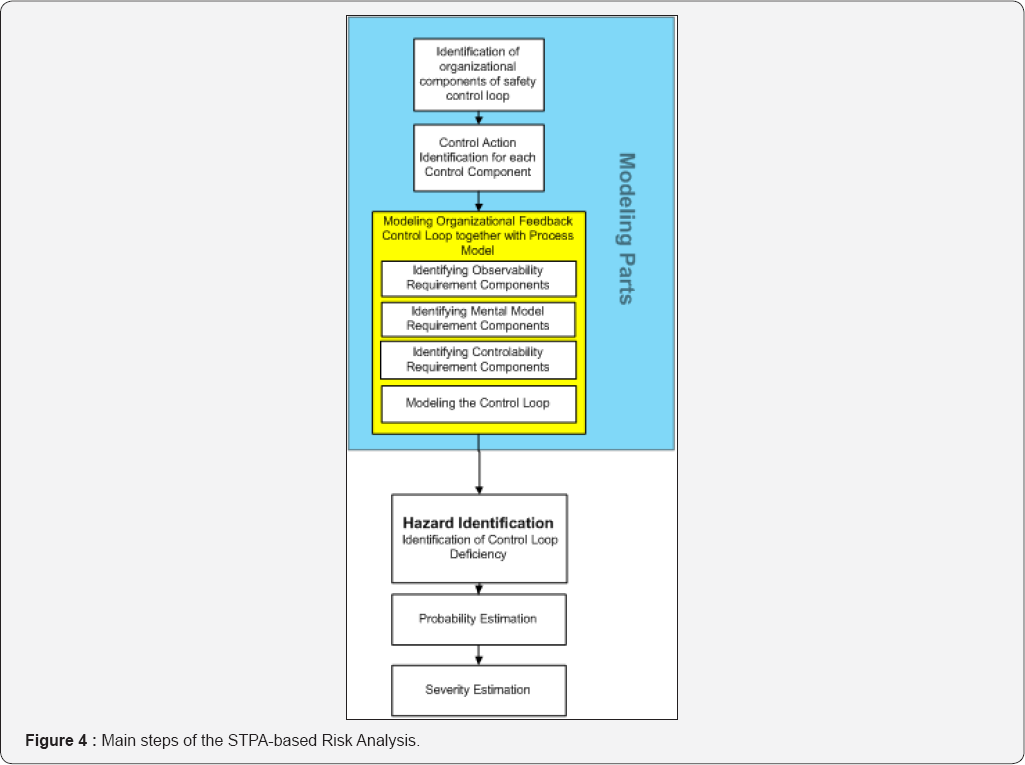

Modelling the system's organizational safety control loops: Based on Figure 4,

for modeling the system organizational safety control loops (As the

initial step of the Hazard Identification Process) a sequence of

procedures are needed that are described in the following.

Identification of organizational components of safetycon- trol loop :

Before modeling the safety control loops for each control action of all

control components, as a main part of STPA, the control components must

be identified. Since our risk analysis model concentrates on

organizational roots of probable accidents, we focus on "organizational

control components" and their associated control actions.

Dulac recommended three important in formation

sources to identify Safety control Structure's organizational

components. Additionally, he recommended two criteria to summarize this

information for elicitation best set of these components [30]. These recommendations are reviewed as follow:

a. Org charts (Source one): He mentioned that, organization’s charts are a good start line for identification of organizational components.

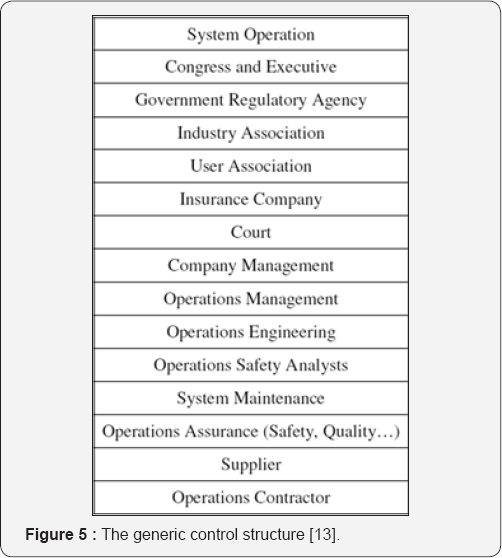

b. Generic STAMP structures (Source two): The generic control structure that was shown in Figure 5,

can be used as an effective checklist to verify that important

components have not been mistakenly left out. He noted that, for many

systems, it is unneeded to follow the hierarchical structure all the way

up to the Congress and Executive components.

c. Interview data (Source 3): Another source

for identification safety control structure’s organizational components

is the interviewing from individuals within the structure itself. Dulac

stated that the emphasis should be on reviewing, improving and refining

the structure, eliciting informal structural connections that are not

represented in the official “party-line” organization chart.

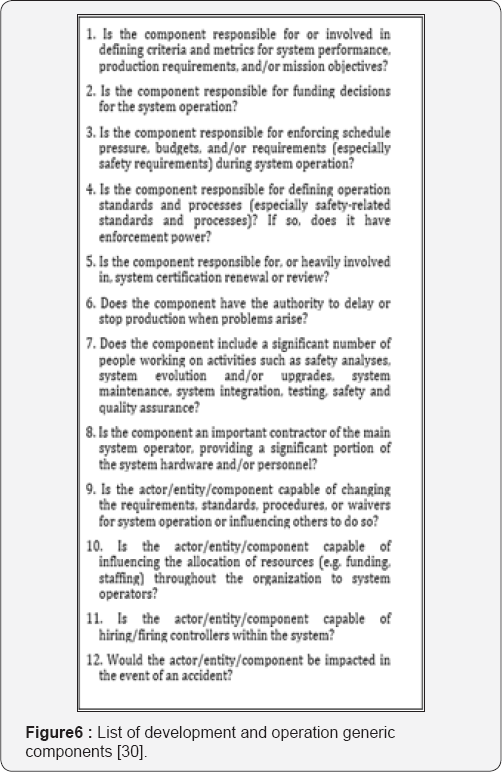

d. Inclusion criteria (Criterion 1): He

prepared eight questions in order to decide whether an organization

component should be included in the model or not. However, Stringfellow

has added four more questions to the list for consideration of more

social features of the control structure [31]. Figure 6 lists the complete questions.

e. Combination criteria (Criterion 2): For

preventing of unnecessary complexity in control structure's model, it

can be possible and desirable to combine multiple components. As a

general rule, components that are structurally independent, but

functionally similar, should be combined unless they receive funding

from completely different or competing sources, or if they have

competing.

Control actions identification: Control

Actions are the actions that are enforced by control components to

control the system behaviors. Clearly, Control Actions are the reason

d’etre of the control components.It should be noted that, each

identified control components may apply different Control Actions to

control their under control processes; therefore, identifying all

components' Control Actions just is possible by scrutinizing all of

related documents and interviewing with organizational experts. Finally,

the results should be listed in an appropriate log [32].

Organizational feedback control loop modelling:

Now, in order to model organizational Feedback Control Loops - based on

the mentioned exclusive modelling diagram - all NonControl Actions

(Necessary Sensing Mechanisms and Analytical Mechanisms) must be

explored for each control component. Then, all requisite mechanisms, as

the Non-Control Actions, for accurate enforcement of each Control Action

must be specified. Finally, all Feedback Control Loops - together with

their Process Model - must be modeled according to the pattern that has

been presented in Figure 3.

Organizational hazard identification: “Working

around the loop” is the STPA’s principle to extract the hazards. In

fact, each of control loop's component should be regarded as a potential

source of systemic hazard; because any inefficient performance of them

can be able to cause a degree of incompetency in the control loop. This

local deficiency, consequently, eventuate to a level of inefficiency in

the whole system safety control structure; and, in a bigger picture,

leads to the system accost to a probable accident [33].

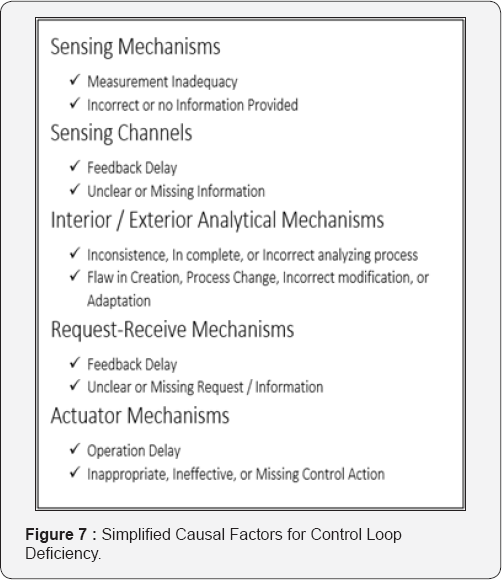

Accordingly, by using the Simplified General Causal

Factors, which are adapted from STPA original model and shown in Figure

7, different statuses of "Control Component Inefficiency" could be

extracted and regarded as the initiating mechanisms for systemic

accidents. These initiating mechanisms thus should be recorded as a

specific hazard for the probability and consequence estimation.

Risk estimation

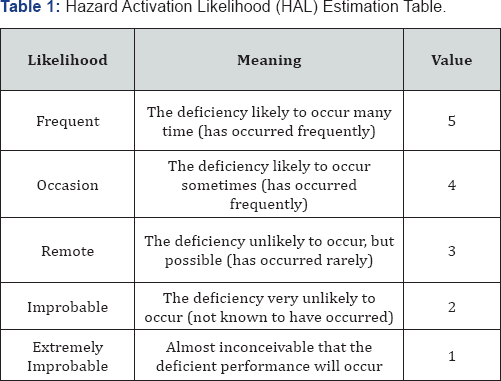

Hazard activation likelihood (HAL): While

hazard is a dangerous dormant situation that triggers a mishap if will

be activated, the likelihood of the hazard is the probability of the

hazard activation. When we consider the hazard as the Deficiency in

organizational safety control mechanisms, we prepare this opportunity to

evaluate the Hazard Activation Likelihood (HAL) via the ratio of the

imperfect performances of the mechanism and the desired performance of

it at a specific period. Also, we can make a qualitative conception of

HAL by regarding experts' opinions and applying Table 1, if the reliable performance data is not available [34].

Hazard activation consequences severity (HACS) analysis:

In addition to Hazard Activation Likelihood

estimation, we need a clear rule to estimate the Hazard Activation

Consequences Severity (HACS), if we want to estimate the risk of any

hazards.

For making an appropriate way to estimate the

severity of the hazard activation consequences, we change the concept of

"consequence" from the real results of hazard activation (happening the

real mishap) to a new measurable quality that directly linked to

control theory. Actually, instead of seeking and modeling the

imperceptible results of defective mechanisms (as the hazards) on the

probable accident scenarios, we focus on the negative consequence of the

identified defective mechanisms on the whole Organizational Safety

Control Structure’s Competency (OSCSC).

This substitution can be meaningful because based on

STAMP pivotal thought, accidents in complex sociotechnical system happen

when the safety control structure cannot be able to control the

system’s behavior. As a result, it can be hypothesized that a defective

mechanisms are able to cause a kind of deterioration on the safety

control structure, and then, the dormant systemic hazards become active

and initiate a complex and imperceptible chain of events that finally

eventuate to a mishap; or at least, can push the system toward a more

hazardous situation [35].

When it is impossible to estimate the role of a

specific defective mechanism on the formation of accident scenarios, it

can be feasible to be focused on "consequent deterioration” in safety

control structure; the deterioration that can be regarded as a preceding

status of a probable catastrophic accident.

The whole OSCSC is an abstract concept that shows

"how well safety control structure enforces desirable system safety

constraints”. This concept stands on the system theory, the control

theory, and specifically, main concept of STAMP and STPA model.

According to these theories and models, the main mission of "Safety

Control Structure" is to enforce specific constraints to ensure that the

system will be keeping in a safe zone when has to tolerate unavoidable

and continuous changes. In fact, system's control structure must have an

appropriate dynamicity to constrain the real dynamic system in each new

position.Nevertheless, in a specific point of time, the real control

structure may not completely conform to the desired control structure.

This unconformity and gap may have some causes such as control structure

design inappropriacy, imperfective performances of some control

structure's components, or unfit adaptation of the control structure [36].

Accordingly, the whole OSCSC is a concept that can be

able to reflect the experts’ overall opinion about the real control

structure proficiency. The experts, in fact, are able to qualitatively

estimate the effect of a specific deficient mechanism, which was

explored in the hazard identification phase, on the Safety Control

Structure's Competency. The severity of this effect, consequently, is

able to take the place of the "Hazard Severity" in the risk analysis

procedure [37].

Risk evaluation

Risk evaluation is the process of comparing estimated risks with established risk evaluation

Case Study (Figure 8-10)

Summary and Results (Figure 11)

Conclusion and Discussion

For precise evaluation of OSCSC, certainly, we need

more data to model the relation network between safety structure's

components;nevertheless, in the initiating phase of organizational risk

analysis we can rely on experts judgment.

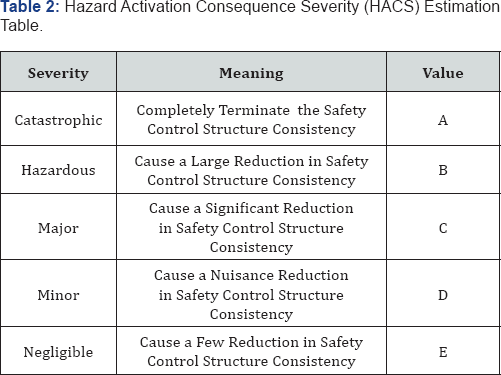

Table 2

is presented to estimates the severity of a consequence that is

initiated from specific organizational hazard by extracting experts'

opinions.

Finally, the estimated risk is described in a

qualitative term by a combination of two characters that the first

demonstrates the Hazard Activation Likelihood (HAL) and the second

demonstrates the Hazard Activation Consequence Severity (HACS); such as

3A, 5B and the like.

Criteria (e.g. criteria based on the best available

technology, legal requirements, practices, processes, or achievements)

in order to determine the level or significance of risks and provide

recommendations for the decision-makers at various levels [6].

Although "Risk Evaluation" is beyond this paper’s scope, As Low As

Reasonably Practicable' (ALARP) strategy usually employs for managing

the risks. In the case study section, a simple table is applied as a

sample for the risk evaluation criteria.

In the following, the presented STPA-based

organizational risk analysis framework is applied - in limited scale -

to extract organizational safety-related hazards and estimate their

risk. The case is a sample aviation industry that is responsible for

maintenance and modification of Iran’s helicopter fleet.

Accordingly, only two organizational safety control

components together with their related communication mechanisms, and

their inter-connected non-control components (analyzing or supporting

components) were selected for further analysis. These two organizational

components include Quality Control (QC) unit, and Research &

Technology (R&T) unit. The first one is responsible for managing the

main and the most comprehensive control mechanisms in case industry.

The second one controls modification projects via its ratification

authority.

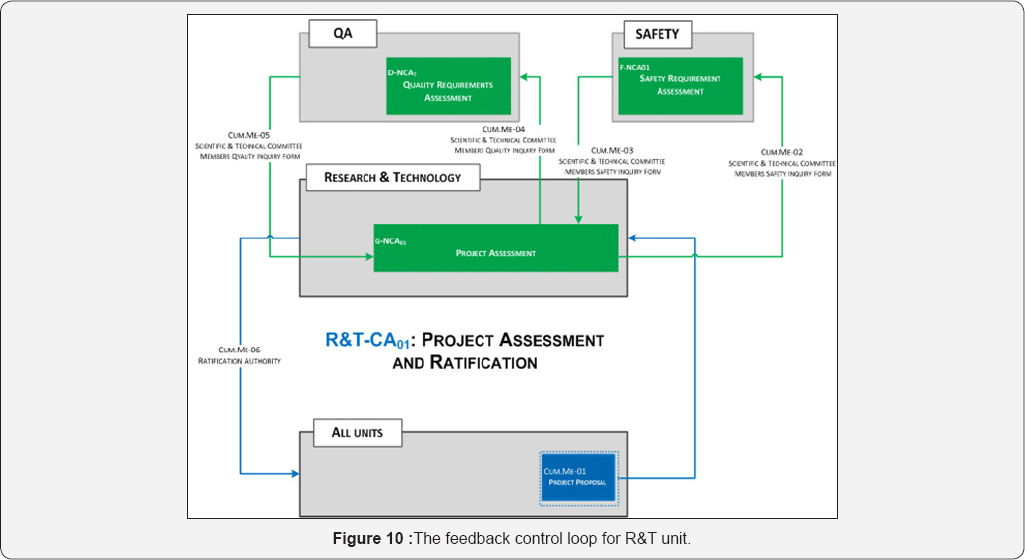

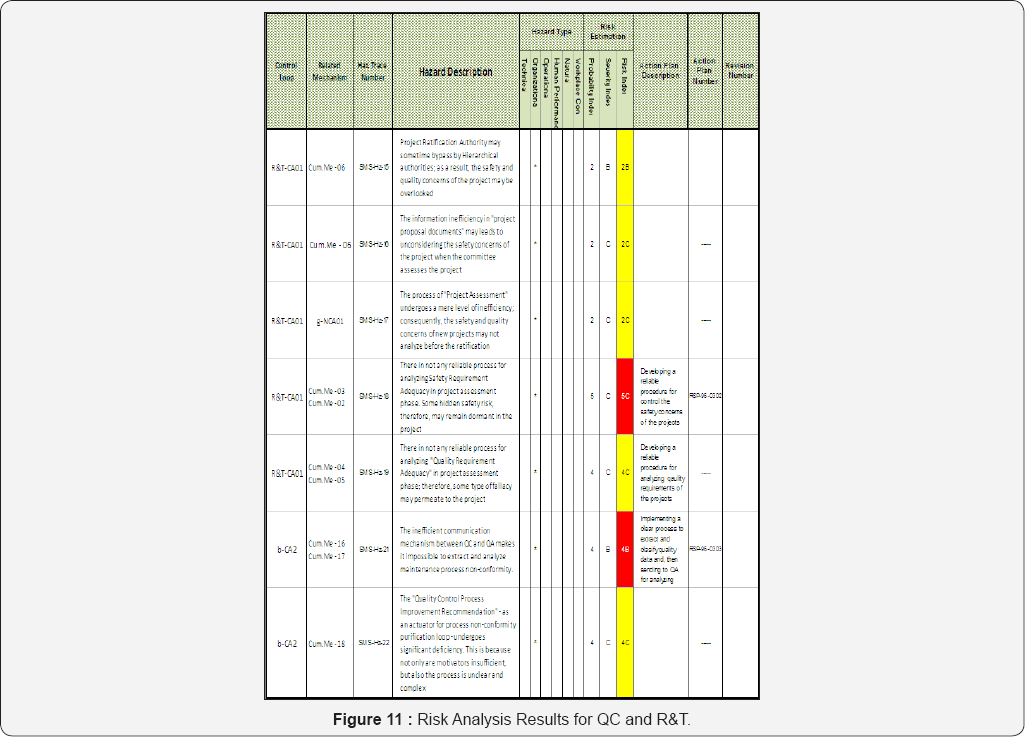

Based on the modeling pattern, which is illustrated in Figure 3, all control requisite mechanisms have been identified and, then, the control loops have been made (Figure 8 For QC and Figure 9 for R&T).

After modeling the control loops, all parts of the loops have been analyzed by means of the Simplified Causal Factors (Figure 7)

in order to extract any probable deficiency; then, a group of experts

estimated the probability of each extracted deficiencies via applying Table 1. This group of expert, then, applied Table 2.

to estimate the probable consequence of the identified hazards on the

whole OSCSC; after all, the risks of the hazards are evaluated by means

of Figure 10; as a simple method for prioritizing the necessary control actions. Finally, the results have been summarized and depicted in Figure 11.

For initiating the process of organizational-based

safety risk analysis in aviation industries, which is needed concerning

ICAO's safety management system (SMS), an innovative and specific

framework have been presented in this paper. This framework was built on

the Control Theory and, specifically, the STPA model. Based on this

model’s main concept, catastrophic accidents in complex socio-technical

systems originate from the Safety Control Structure deficiency.

Accordingly, the new framework is concentrated on Organizational Safety

Control Loops deficiency (as the hidden hazards) and the effect of these

deficiencies on the whole Organizational Safety Control Structure

Competency (as the consequence of the hazards).

For presenting the main procedures of the framework,

its modeling and analyzing parts were described separately. The modeling

part is made of a series of steps to identify organizational control

components, control actions, and model the control loops. The analyzing

part is responsible for extracting defective mechanisms that are placed

in control loops by use of a series of guide-words, which is named

Simplified Causal Factors. This part also is responsible for evaluating

the Hazard Activation Likelihood and the severity of Hazard Activation

consequences.

For estimating likelihood of the hazards and severity

of the consequences, two specific tables were presented as the guide

tools for experts' judgment. Finally, the framework was limitedly

applied in a case aviation organization to clear its sequence and

procedures, as well as its applicability.

The presented framework is developed for analyzing

the organizational-based safety hazards that are hidden in the

operational phase of the system. We, consequently, assumed that all

high-level hazards of the system had been identified and adequate

control components with clear responsibilities had been embedded in the

system to control them; however, it is possible that some of the control

mechanisms had been eroded or outdated in the result of system dynamic

behavior.

According to this assumption, we neglected some of

initiating steps of STPA that are related to "System-Level Hazard

Identification" and "Safety Constraints Identification". In fact, we

started the hazard identification process from extracting current

organizational control components and their responsibilities.

Nevertheless, we admit that a comprehensive analysis, which should be

done in the next rounds of a continuous risk management cycle, must

start at "System-Level Hazard Identification" and continue separately

for each system-level hazard.

Furthermore, a more advanced analysis should be

developed based on more quantitative and precise data for "Hazard

Activation Likelihood" and "Hazard Activation Consequences Severity"

estimation. Increasing preciseness of these two quantities can be able

to help system engineers and decisionmakers to find and concentrate

critical mechanisms of the control structure for launching more

appropriate improvement plans.

In addition, the evaluated risk (the combination of

HAL and HACS) of each safety-related organizational mechanism has a

meaningful dynamic feature. This is because both the imperfect ratio of

organizational mechanisms and the whole Organizational Safety Control

Structure Competency are sensitive to organizational dynamicity. As an

important result, the estimated risk could help system engineers to

design remarkable leading indicators as the predecessor of system

hazardous behaviors.

For More Open Access Journals Please Click on: Juniper Publishers

Fore More Articles Please Visit: Civil Engineering Research Journal

Comments

Post a Comment