Optimal Pump Scheduling Considering Resetting Reservoir to Minimum Level and Rescheduling due to Pump Maintenance- Juniper Publishers

Juniper Publishers- Journal of Civil Engineering

Abstract

In this paper we consider two pumping stations, one

with three pumps that can be run individually or as combinations and the

other with one pump as well as daily maximum volume restriction on

water to be pumped out. Night electricity tariffs are lower than day

tariffs. Each hour has its constant demand except the 7th hour where demand varies, 7th

hour demand variation notice is sent a day before by the water

customer. Water from these pumping stations is pumped to a high point

service reservoir so that pressure level can be maintained on taps.

Service reservoir has a capacity of 10000m3 and the water level should

not go below 40% full in order to safeguard supplies in the event of

burst water and to meet sudden demands such as firefighting. Linear

programming is used to determine which pump combination is to be used

during which hour as well as developing optimal schedules when any pump

is under maintenance

Keywords: Scheduling; Linear programming; Water pumps; Pump maintenance

Abbreviations: IP: Integer Programming; MOEA: Multi-objective Evolutionary Algorithms

Introduction

Significant percentage of energy consumption in the

world is used for pumping purposes as a result there is need for pump

scheduling with objective of minimizing electricity consumption. Ordan

et al. [1]

developed a new methodology for optimized real-time operation of a

water distribution. The methodology is based on the integration of three

models, namely the real-time demand forecasting model, the hydraulic

simulation model, and the optimization model. The optimization process

is driven by the cost minimization of the energy used for pumping and

the maximization of operational reliability. Optimal pump schedules were

generated by using a multi-algorithm-genetically-adaptive- method

(AMALGAM), they also performed hydraulic simulations using the EPANET2

model. Lansey and Awumah [2]

presented a methodology for determining optimal pump operation

schedules for water-distribution systems. In addition to minimizing the

energy-consumption cost, their model includes a constraint to limit the

number of pumps that are switched on during the planning period. They

also adopted a two-level approach whereby the system hydraulics are

analyzed in an off-line mode to generate simplified hydraulic and cost

functions for an on-line model. These functions developed for each pump

combination allow for rapid evaluation within a dynamic programming

optimization algorithm.

Racca et al. [3]

presented a new optimal pumping scheduling model that integrates the

evaporation losses from the reservoirs into the optimization algorithm

and provides the optimal pumping policy that minimizes both pumping and

water costs. Multi-objective Evolutionary Algorithms (MOEAs) were

considered to solve an optimal pump-scheduling problem with four

objectives to be minimized, thus electric energy cost, maintenance cost,

maximum power peak, and level variation in a reservoir [4]. Wang et al. [5] enhanced genetic algorithm for bi-objective pump scheduling in water supply. Hyeong-Seok et al. [6]

applied a binary integer program to optimize pumping schedule of a

water supply system in Polonnaruwa, Sri Lanka based on the hourly water

demands for the next day. The water demands were forecasted by a

combined model consisting of an autoregressive integrated moving average

model and an error compensation routine based on exponential smoothing

technique. The result showed that the optimization system could reduce

the operation cost of the WSS by minimizing electricity for

water-pumping; electricity cost for pump operation could be reduced by

55%. For the past decades, a few forecasting methods have been applied

to optimize pumping schedules of WSSs [7]. Genetic algorithm also has been applied for minimization of pumping cost through intermittent water pumping in a WSS [8].

Giacomello et al. considered a hybrid optimization method for effective

pump scheduling. They solved the problem by a novel hybrid optimization

method that uses linear programing and a greedy algorithm. Naoum-Sawaga

et al. [9]

proposed new approaches for water pump scheduling and pipe replacement,

they also applied a knapsack based heuristic for the leak pipe

replacement problem. Jowitt and Germanopolous [10]

considered a method based on linear programming for determining optimal

schedule of pumping on a 24 hour basis. They considered both unit and

maximum demand charge, as well as efficiencies of the available pumps,

the structure of the electricity tariff, the customer demand profile,

and the hydraulic characteristics and optimization constraints of the

network. Sakarya and Mays [11]

determined optimal operation of water distribution system pumps with

quality considerations. Integer programming (IP) was also applied by Kim

et al. [12], Biaszczyk et al. [13]

presented the optimal pump scheduling for a large scale water

distribution system by applying linear programming to optimize the

operating schedule of the pumping system in the Seoul Metropolitan area.

They used a multiple regression model to forecast hourly water demands.

Bagirov et al. [14]

introduced a novel approach for modelling of explicit pump scheduling

to minimize energy consumptions by pumps which uses the pump Start/ End

run times or continuous variable, and binary integer variables to

describe the pump status at the beginning of the scheduling period.

Pasha and Lansey [15]

linearized pump stations relationships using relationships among energy

required, pumping flow, demand factors, tank storage or tank water

levels. They formulated a linear programming model and solved for a

single tank system for the optimal pump schedule to minimize energy

costs. Bragalli et al. [16]

proposed a method to design optimal distribution reservoirs and their

operation using non-linear programming. Price and Ostfeld [17]

examined problem that includes nonlinear convex headloss, leakages and

varying total head pump energy consumption constraints. Savic et al. [18]

introduces multi-objective Genetic Algorithms (GAs) for pump scheduling

in water supply systems. The two objectives considered were

minimization of energy and maintenance costs. Pump switching were

introduced as a surrogate measure of maintenance cost. The

multi-objective algorithm was compared to the single objective GA, with

both techniques improved by using hybridization with a local-search

method.

Statement of the Problem

Distribution of potable water requires that water is

pumped to reservoir at high point in the system. Pumping uses

electricity which has a cost which varies through the day. Considerable

saving in electricity costs can be made by choosing when pumping is done

but pumping patterns are constrained by the necessity to safeguard

supplies. In this case study water is obtained from three different

types of source

1. Surface reservoirs,

2. Underground, and

3. Abstraction from rivers.

Water is treated in various ways to make it both safe

and acceptable to drink. The treated water is pumped to the reservoir.

The service reservoir is situated at high points of the distribution

system so that the water pressure is maintained at the taps. Since the

service reservoir is at high points of the system it is necessary to

pump treated water to this reservoir. Often there are several pumps at

the pumping station which are situated at the water treatment works.

Various combinations of pumps can be used at the request of the

operator. Pumps can be controlled either by switching them on or off.

The water companies spend a lot of dollars per annum on electricity of

pumping water. Table 1

gives electricity tariff which clearly shows that pumping is cheaper at

night than during the day. The flow of water down a pipe is subject to

some frictional force from the walls of the pipe which increases at the

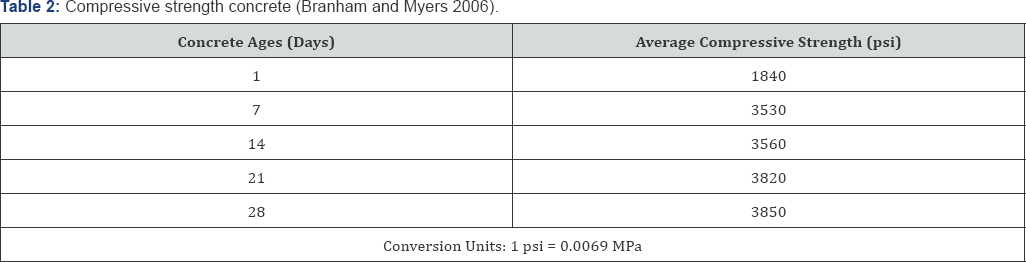

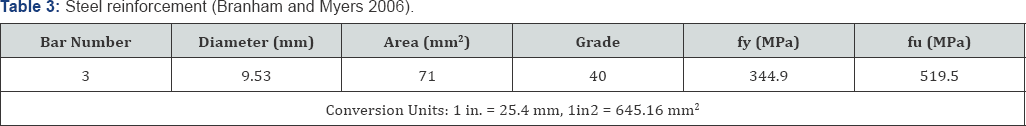

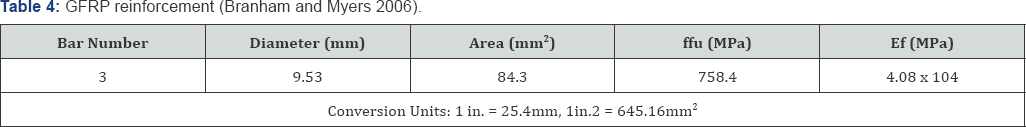

rate of flow of water increases. Table 2 & 3

gives the power consumption and flow rates for all possible

combinations of pumps at Nyamandlovu and Sgodini pumping stations which

supplies the Bulawayo reservoir. The Esigodini treatment works can only

treat 2000 cubic meters of water per day. The hourly demand for water

for the Bulawayo community is given in Table 4.

The Bulawayo service reservoir has a capacity of 10000 cubic meters and

the water level should not go below 40% full in order to safeguard

supplies in the event of burst water and to meet sudden demands such as

for firefighting. A pump schedule is a set of instructions to the

operator as to when the pumps at a pump station must be switched on and

off. A pump schedule is needed that satisfies demand at the minimum

costs while satisfying constraints of the water level in the Bulawayo

service reservoir. Pump reschedule is also necessary when a certain pump

is under maintenance so as to optimally pump water with the available

pumps.

A unit cost for every kilowatt hour energy that is used is given in the Table 1.

Sgodini Station has 1 pump (Table 2).

Nyamandlovu Station has three pumps, two of type A and one of type B pump which may be run in any combination given in Table 3 below.

Linear Programming

Linear programming model is modelled in such a way

that the solution output indicates minutes in a given hour a pump or

pump combination is supposed to be switched on and off during the day

and night. The model output is such in a way that it can be used to draw

up pump schedules as well as determining the utilization of pumps.

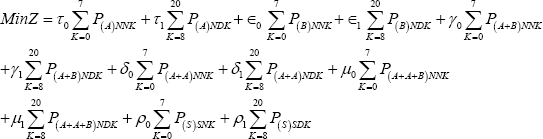

Linear programming model parameters

τ0 —— Hourly cost for using pump (A) during the night

τ1 Hourly cost for using pump (A) during the day

ϵ0 Hourly cost for using pump (B) during the night

ϵ1 Hourly cost for using pump (B) during the day

γ0 Hourly cost for using pump combination (A+B) during the night

γ1 Hourly cost for using pump combination (A+B) during the day

δ0Hourly cost for using pump combination (A+A) during the night

δ1Hourly cost for using pump combination (A+A) during the day

μ0Hourly cost for using pump combination (A+A+B) during the night

μ1Hourly cost for using pump combination (A+A+B) during the day

ρ0Hourly cost for using pump (SGODINI) during the night

ρ1Hourly cost for using pump (SGODINI) during the day

D;KDemand during hour K

Θ Output flow rate of pump j in cubic metres per hour, and j

= Pumps (A,B, A+B, A+A, A+A+B, SGODINI)

p (j) NNK → Pump j at Nyamandlovu, during the Night, during hour K, and j

=Pumps (A,B,A+B,A+A,A+A+B,)

p (j) NDK → Pump j at Nyamandlovu, during the Day, during hour K, and j

=Pumps (A,B,A+B,A+A,A+A+B,)

p (j) SNK → Pump j at Sgodini, during the Night, during hour K, and j=SGODINI pump

p (j) SDK → Pump j at Sgodini, during the Day, during hour K, and j=SGODINI pump

μ Reservoir capacity

® S — SGODINI pumping station capacity

℧ K — Water accumulated at hour K

Linear programming model

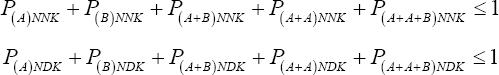

Constraint set number 1

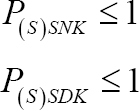

Constraint set number 2

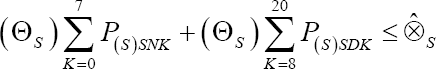

Constraint set number 3

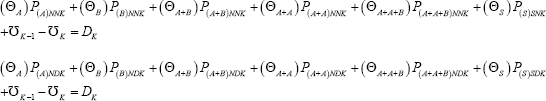

Constraint set number 4

Constraint set number 5

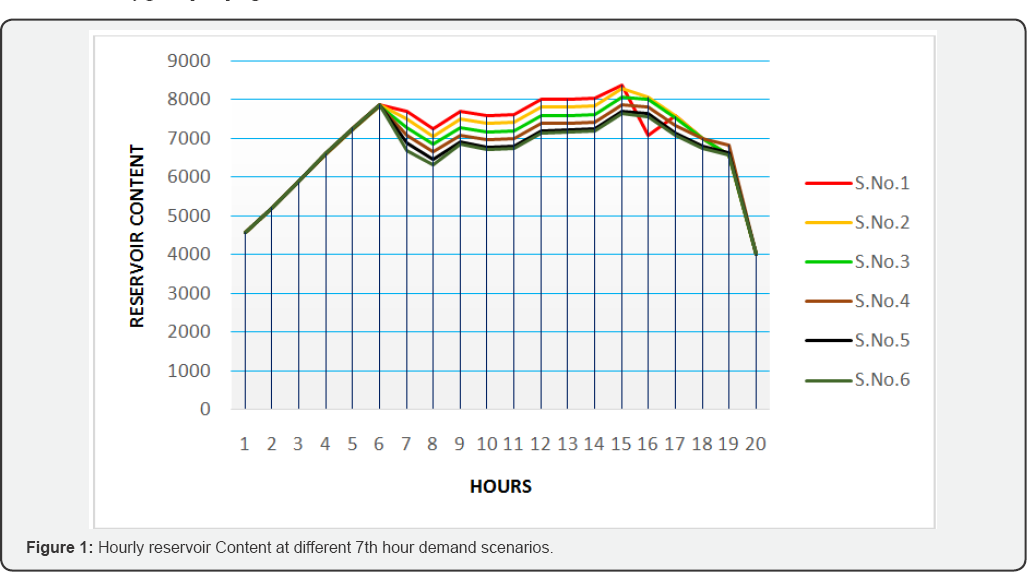

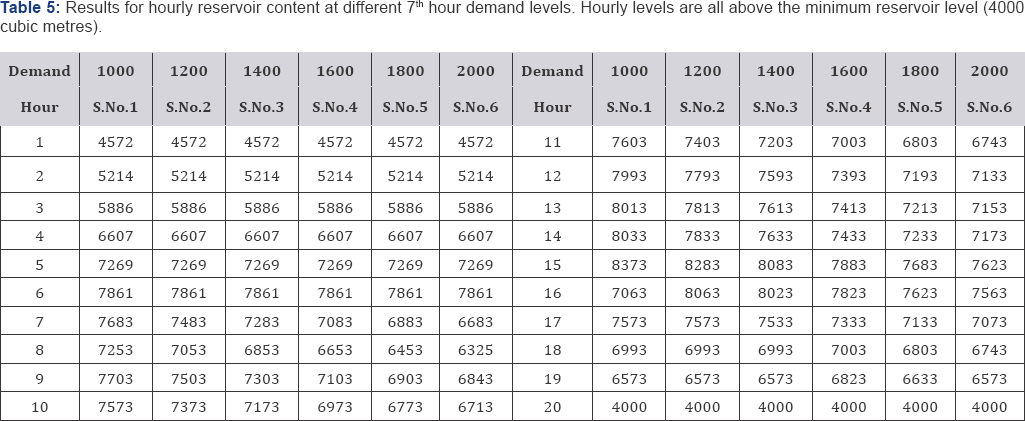

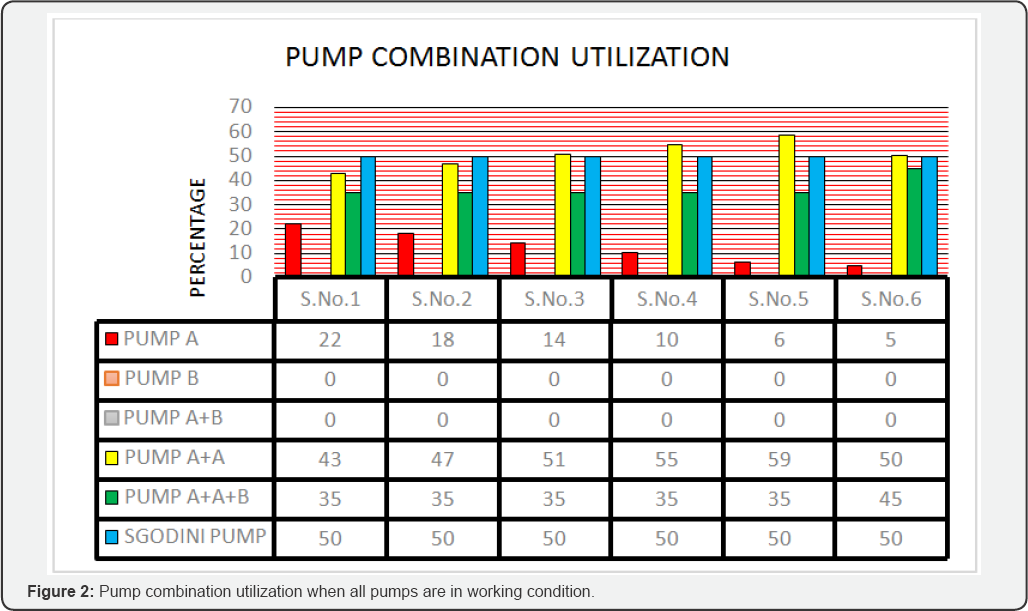

Results (Table 5 & 6, Figure 1 & 2)

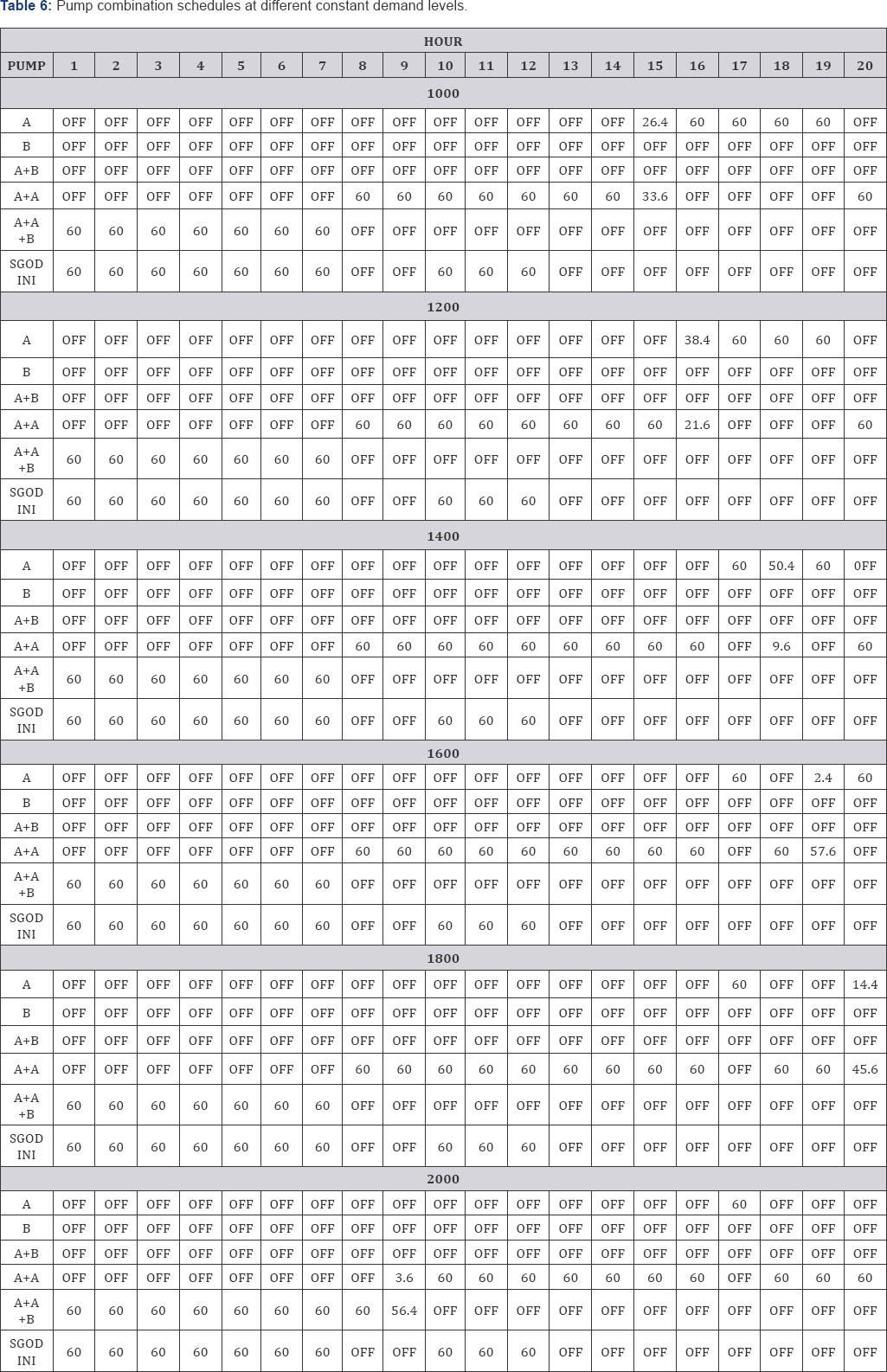

Table 6

shows how many minutes a pump is supposed to be switched on in any

given pumping hour. It is from this table where pump utilization

information is taken from. Optimal scheduling cost at different 7th

hour demand scenarios are as follows: 1000 cubic meters ($110.16), 1200

cubic meters ($113.36), 1400 cubic meters ($116.56), and 1600 cubic

meters ($119.76), 1800 cubic meters ($122.96), and 2000 cubic meters

($126.84).

Utilization of Pump A decreases as demand level

increases, this indicates that Pump A is not economic and optimal to use

for long time when demand level is high. Sgodini pump utilization level

is uniform even if demand is increasing. Pump combination (A+A) and

(A+A+B) increases utilization level as demand increases, this is so

because these pump combinations are able to pump high volumes of water

to satisfy increasing demand levels as well as minimum reservoir

content.

Pump Rescheduling

We assume that at most one pump is under maintenance

in any given day. The unavailability of any given pump due to

maintenance doesn't only affect the total number of pumps available, but

it also reduce the total number of pump combinations to be used. In

this case we want to make use of available pump combinations to

optimally pump water to Bulawayo reservoir. On the other hand we should

bear in mind that we are only supposed to pump water to our customer if

and only if we can satisfy the 7th hour demand, thus not violating minimum reservoir level restrictions in the pumping long run.

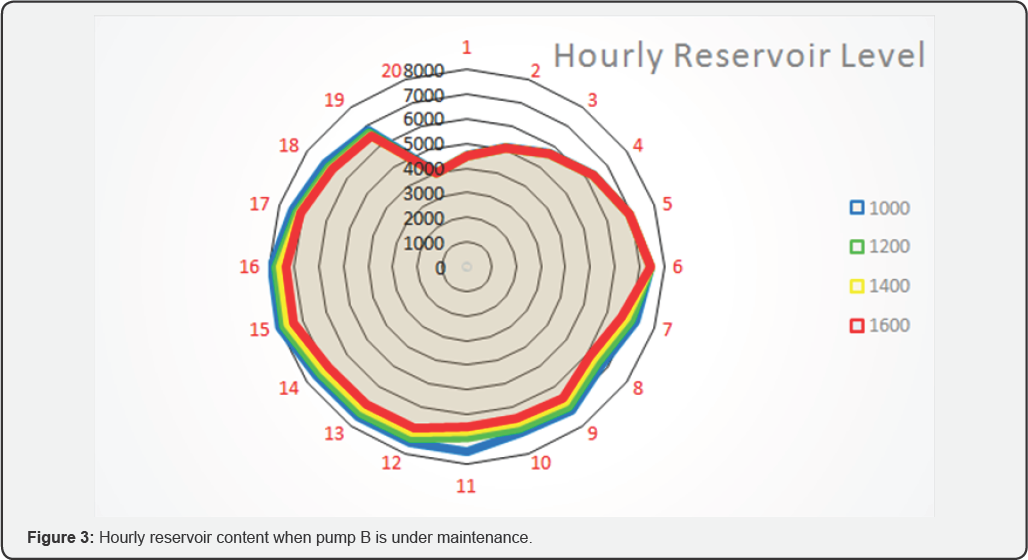

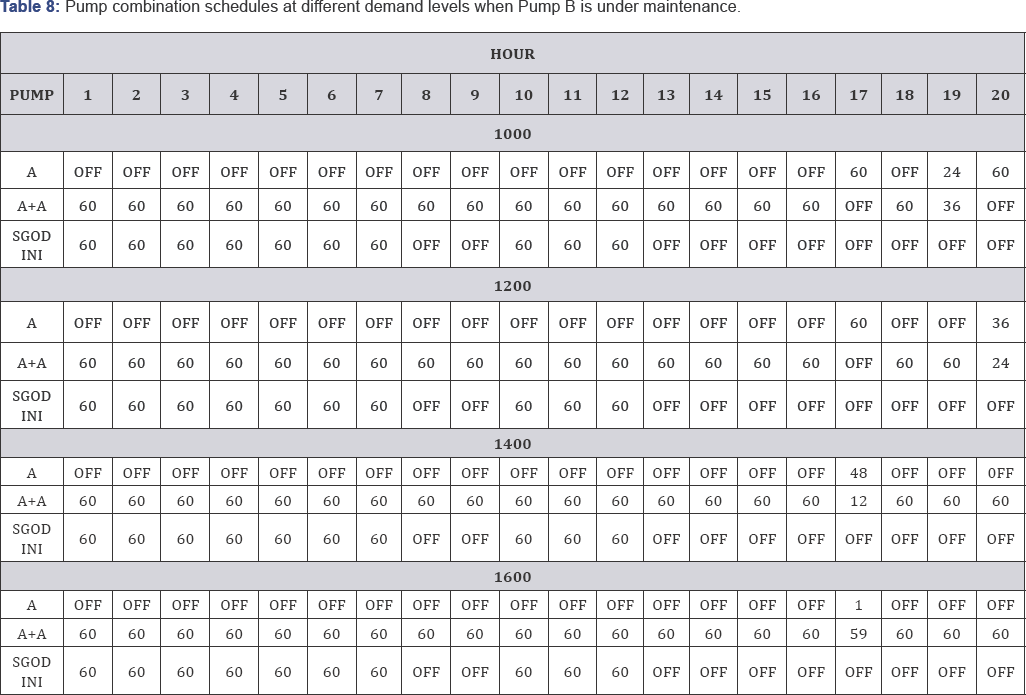

Assuming that pump B is under maintenance

When pump B is under maintenance, we remain with

three pumps to be scheduled, thus pump A, A+A, and Sgodini pump. These

pumps when scheduled using linear programming the solution lies within

the infeasible region when demand is above 1600 cubic meters (Table 7, Figure 3).

When pump B is under repair, we have three pump

combinations to be scheduled thus, Pump A, Pump A+A, and Sgodini pump.

These pumps were scheduled in such a way that minimum reservoir content

was not violated as well as When Pump B is under repair or maintenance

these pumps combinations can only pump a maximum 7th hour

demand of 1600 cubic metres. In general when pump B is not working we

cannot supply a demand above 1600 when using available pumps. Optimal

scheduling cost at different 7th hour demand scenarios are as follows:

1000 cubic meters ($114.65), 1200 cubic meters ($117.85), 1400 cubic

meters ($121.76), and 1600 cubic meters ($128.56) (Table 8, Figure 4).

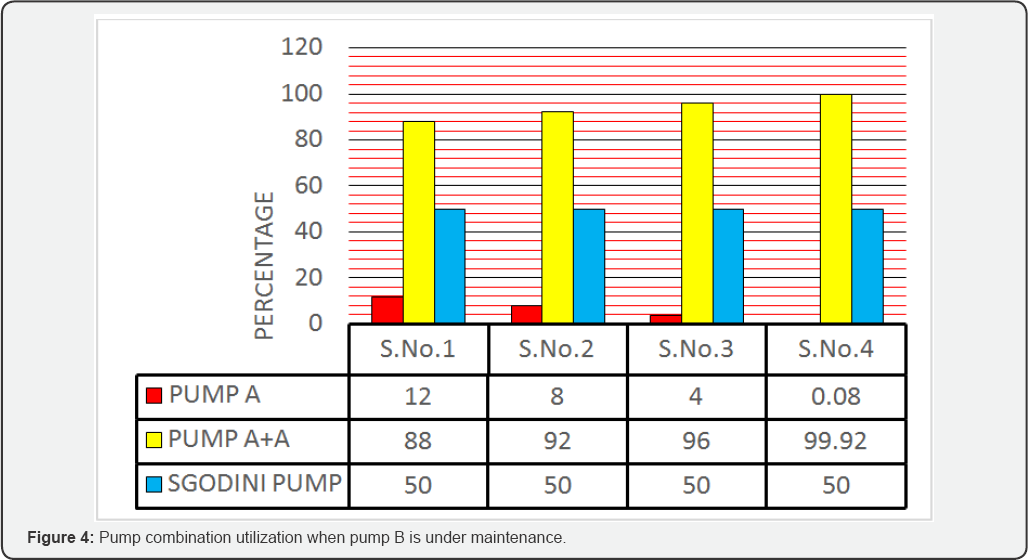

Pump (A+A) utilization factor as demand level

increases. When demand level is at 1600 cubic metres pump (A+A) has to

work almost throughout the day, with 99.92% utilization, and pump A is

utilized for 0.08%, and this implies that pump A is not capable, optimal

or economic when demand level increases. Utilization of Sgodini pump is

uniform throughout deferent demand levels (50%).

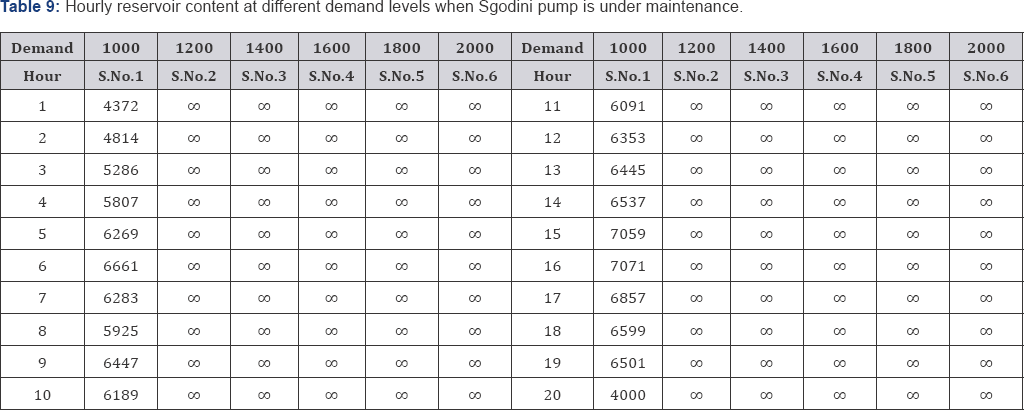

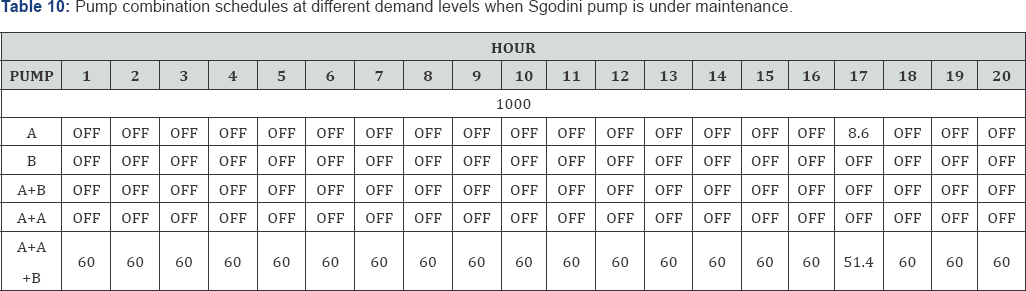

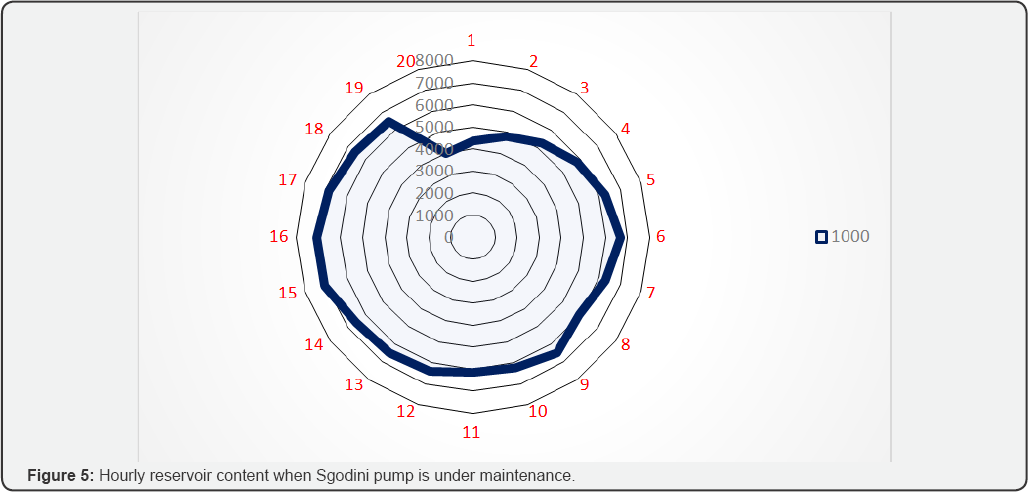

Assuming that sgodini pump is under maintenance

When Sgodini pump is under maintenance, pumps A, B,

A+A, A+B, A+A+B are the ones available for rescheduling. The optimal

schedule of these pumps cannot supply demand capacity above 1000 cubic

meters. The optimal cost for pumping when 7th hour demand is 1000 cubic meters is $144.75 (Table 9 & 10, Figure 5 & 6).

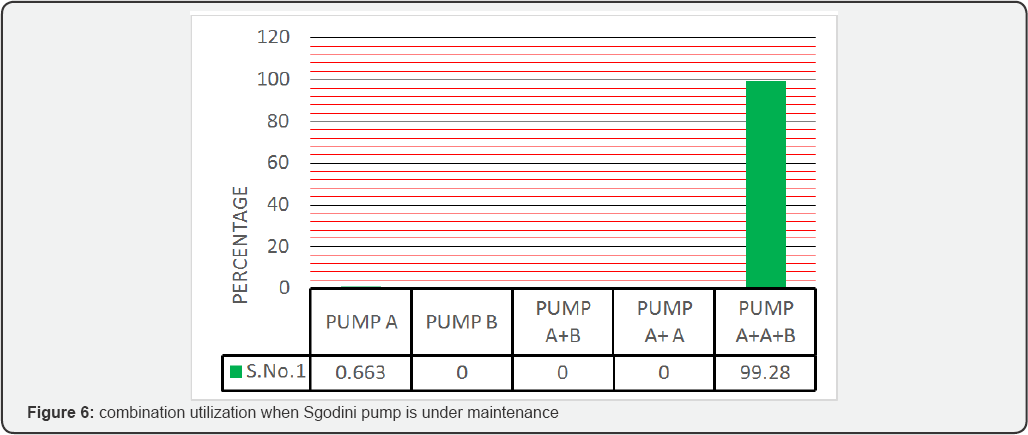

When Sgodini pump is under maintenance we can only

supply a minimum and a maximum of 1000 cubic metres. The utilization of

pumps are as follows, Pump A (%0.663), Pump B (%0), Pump A+B (%0), Pump

A+A (%0) and Pump A+A+B (%99.28). This indicates that Sgodini pump in

important pump type when supplying levels of demand more than 1000 cubic

metres. On the other hand this reveals that Pump B, Pump A+B, and Pump

A+B are dependent of Sgodini pump. When Sgodini pump is under

maintenance, any demand level more than 1000 cubic meters lies within

the infeasible region.

Assuming that pump A is under maintenance

When pump A is under maintenance, pumps B and Sgodini

are the only ones available for rescheduling. The solution for

scheduling these pumps lies in the infeasible region. This implies that

they are not capable of supplying the 7th hour demand levels.

Conclusion

We have significantly demonstrated how linear

programming can be used to optimize pumping costs as well as scheduling

1600 pump combinations. Since we can supply a maximum of cubic meters

when pump B is under maintenance, a maximum cubic metres when Sgodini

pump is under maintenance, 100 of and a maximum of zero cubic meteres

when pump A is under maintenance, this indicates that pump A is very

useful to meet cubic meters and more. Pump B is useful 1000 demand

levels of cubic metres, 1600 to supply demand level which is more than

pump Sgodini is useful for supplying demand level which is more cubic

metres. In general if the pumping company needs 1000 than to invest in

buying new pumps it has to buy pumps of type A and Sgodini pump type.

Furthermore, the results have shown that Pumps (B, A+B, A+A) are not

economic or capable when Sgodini pump is under repair, this is evidenced

by their utilization of .zero percent when Sgodini pump is under

maintenance

For More Open Access Journals Please Click on: Juniper Publishers

Fore More Articles Please Visit: Civil Engineering Research Journal

Comments

Post a Comment