Assessing the Suitability of the Cold Bending Method in Fabricating Free-form Façade Panels- Juniper Publishers

Juniper Publishers- Journal of Civil Engineering

Abstract

Free-form buildings are one of the latest unique

trends in the construction industry worldwide. A number of projects have

been undertaken in different parts of the world. These structures are

hailed for their stunning aesthetics and jaw-dropping curvatures.

However, the design, fabrication and installation of free-form façades

is very difficult process as it requires unprecedented precision.

Free-form façade construction could yield such distresses as towering

costs, leakages and panel twisting if not well managed from early

stages. The choice of a production method is paramount as it impacts on

both the cost and the aesthetics of the structure. This study dwelled on

the use of cold bending for fabrication of free-form façade panels.

Design BIM data of a small free-form building in Korea and later mock-up

panels was overlapped and compared with the As-built data of the panels

obtained by laser scanning. The discrepancy in the panel data before

and after construction was assessed and attributed to the method of

panel fabrication used. It was then concluded that cold bending is

suitable for fabrication of flat and single curvature metallic panels,

but has limitations for double curvature panels depending on the degree

of curvature and expertise of the fabricator.

Keywords: Free-form construction; Laser scanning; Cold bending; Overlapping comparison; Panelization; Mock-up panel fabrication

Abbreviations: BIM: Building Information Modelling; DP: Digital Project; LIDAR: Light Detection and Ranging; RADAR: Radio Detection and Ranging

Introduction

Background and purpose software

Free-form design has increasingly gained popularity in the recent 'zero' decade [1].

This is mainly attributed to the increase in the use of computers to

easily produce complex designs in a comparatively short period of time. A

free-form building refers to 'all or portion of a building that is

sloped, narrowed, deformed, or consisting of irregular curves instead of

quadrangle' [2].

With the introduction and advancement of digital

design and Building Information Modelling (BIM), the plight of

realization of free-form buildings has become increasingly easier. The

computer applications have enabled world renowned designers like Zaha

Hadid and Frank Ghery, who have come up with the curvy, slender, wriggly

landmarks of the modern age.

The most difficult process in constructing free-form

buildings is to form and fabricate the façade. To incarnate the facade,

the complex geometric shapes of the façade should be divided into the

panels with the forms and sizes that can be manufactured and fabricated

efficiently. Optimization of façade panels is carried out during design

so as to derive the most cost effective and aesthetic panel curvatures.

There are several methods of forming and fabricating

freeform panels used all over the world. The most common ones include

hot bending, cold bending, hydroforming, die forming and others. The

choice of the method to be used depends on the cost, curvature of the

panels, and manufacturing speed. This study focuses on the cold bending

method of metal sheet processing and its application in the forming and

fabrication of free form panels. With cold bending, curved surfaces are

produced by forcefully bending and fixing flat, thick, sheet metal

pieces along the curved surface on site [3].

One of the drawbacks of cold bending on metallic

panels is the visible gaps at the joints of each panel which distorts

the beauty of the façade. However, not so much information has been

published which thoroughly scrutinizes the application of cold bending

of metal panels on free-form buildings. This study intends to assess the

suitability of the cold bending method on free-form buildings by

pragmatically analyzing the difference between the as-built and the

as-planned façade parameters.

Scope and method

The façade panel materials of free-form buildings

include glass, aluminum, steel, Glass Fiber Reinforced Concrete (GFRC)

and many more, among which aluminum is the most frequently used. This

study focuses on the design, fabrication and inspection of aluminum and

GFRC panels to create free-form facades. The followings are research

processes to meet the research objective:

a) Through literature review, the theoretical

drawbacks of the cold bending method were investigated. Two freeform

building projects whose panels were fabricated by cold bending were

identified for practically reviewing real-world problems.

b) Haewoojae, another free-form building fabricated

with the cold-bending method in Korea, was selected to measure the

difference of the as-built from the as-planned. As-built results of

Haewoojae were extracted through 3D laser scanning technology,

overlapped with the as-planned data of the facility, and compared to

gauge the magnitude of deviation with the as-planned data.

c) In order to make the findings of the comparison

more reliable and generally acceptable, mock-up aluminum and GFRC panels

of various curvatures were fabricated under the supervision of a group

of 4free-form fabrication and installation experts.

d) The as-designed and as-manufactured BIM data of

the mock-up panels were also compared with the overlapping method and

the causes of the deviations analyzed. The comparison results were used

to establish the circumstances under which cold bending is applicable as

a method of freeform panel fabrication.

Literature Review

Definitions

Free-form shapes play an important role in

contemporary architecture. To form the curved facade, the facades of the

freeform buildings should be divided into the shape and size that can

allow production and fabrication, which is called panelization [4].

Panelization methods change depending on the shape of free-form

surfaces, designer's intention, and panel creation algorithm. However

they can broadly be classified depending on the shape they take up, for

example, triangular, quadrangular, or polygonal.

Free-form panels can be majorly classified into three

categories according to curvature. Panels with curvature less than 5mm

are termed as flat panels, those with curvature bending in one direction

are termed as single curvature panels, while those with curvature

bending in two directions are classified as double curvature panels [5].

At the design stage of a free-form building,

designers create very complex 3D building shapes that reflect their

design inspiration. The initial panel models to embody these shapes

consist of free curves with curvatures that change in many ways, causing

difficulty in production and fabrication. Designers need to adjust the

initial panel models to secure constructability at reasonable cost while

maintaining the aesthetic quality of freeform shapes and surface

smoothness. This process is called panel optimization [6]. The bigger the curvature, the more difficult it is for the panel to be constructed and thus a higher cost.

Panel forming methods

There are various methods that can be used in forming

metal free-form panels. Cutting, roller bending, and pressing are

methods generally used to fabricate curved surfaces. Special forming

methods such as stretch forming, die casting, single point forming,

die-less forming, hydro-forming, multi-point forming, and explosive

forming have also been used [3].

Various processing methods are used together according to the required shapes of panels. Lee and Kim [3]

carried out the case study of mass customization of double curved metal

façade panels using a new hybrid sheet metal processing technique. The

authors, who were façade consultants on the Dongdaemun Design Park,

which was the first free-form building built in Korea, undertook the

study because the available panel manufacturing techniques at the time,

including cold bending, were not appropriate for the very curvy building

designed by Zaha Hadid.

Cold bending

Metal bending refers to an operation in which a

portion of a metal is flexed along a line or curve until a bend is

obtained. While metals can either be bent at room temperature or with

application of heat,cold bending is a metal bending method by forcefully

bending and fixing flat, thick, sheet metal pieces along the curved

surface on site at room temperature [7].

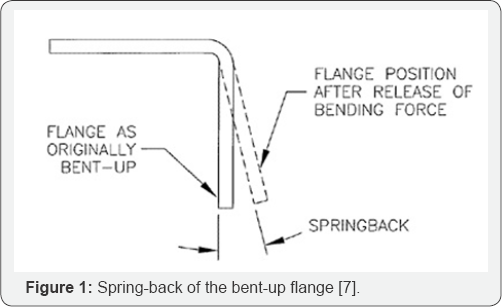

The biggest drawback of metal bending is spring-back,

or back returning force within the metal. A metal always tends to go

back to its original shape after the deforming force has been withdrawn.

Spring-back is 'the amount of elastic distortion a material has to go

through before it becomes permanently deformed, or formed [7]. Figure 1 shows spring-back of a metal flange.

There are several factors that influence the amount of springback of a metal as follows:

a) Ductility of material: Spring-back in more ductile

materials is less than in rigid or less ductile materials. Therefore

metals such as aluminum although fairly ductile with a ductility of 0.65

[8] is bound to experience a certain amount of spring-back when bent.

b) Size of metal segment: Larger area segments tend

to have more spring-back than smaller area segments. Flatness of the

surface is also difficult to produce due to the 'oilcan effect'. This is

when a surface snaps back and forth like an oil can when pressed upon

by hand. It can be corrected through a costly procedure of submitting

the surface to pressures excessive of its modulus of elasticity using

hydraulic press.

c) Bending angle: The sharper the angle the lesser

the spring-back. Obtuse angles are more prone to spring-back than acute

angles. Therefore since the curvature of the freeform panels is not

acutely sharp, even for double curved panels, the panels formed using

cold bending method are bound to deviate from their original curvatures

due to spring-back.

d) Bend radius: The bend radius (curvature) has a

profound effect on the success of the bending operation. The radius

depends majorly on the material thickness and material hardness.

This study identified two free-form building projects

where cold bending was applied. While the projects demonstrated their

aesthetic features with curved facades, some drawbacks were identified

due to spring-back of a metal.

J Museum

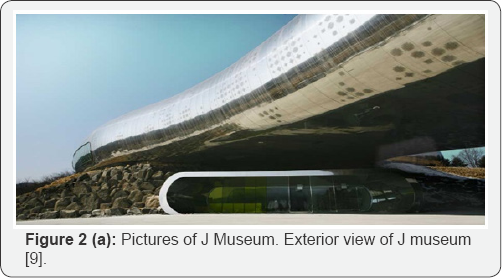

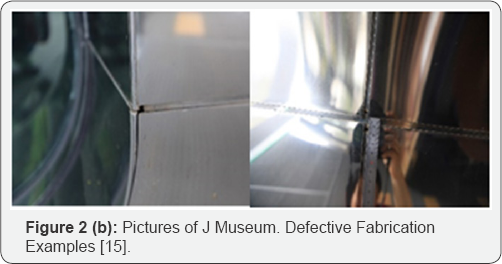

Designed by a France studio XTU architects, Jmuseum

is a meandering free-form structure developed by the regional Korean

government as a part of the efforts to preserve the Asian History and

promote tourism. The double perforated walls of the 6,700m2

building, enveloped with rectangular stainless steel panels, references

the pattern of a reptile skin that reflects the peripheral scenery [9].

Figure 2a

shows exterior view of the stainless steel envelope of the museum.

However, on some parts of the envelops, the panel joints were observed

to be staggering in an irregular pattern, insinuating a problem in the

fabrication or cold-bending method as shown in Figure 2b.

Experience Music Project (EMP)

This is a contemporary popular culture museum located in Seattle Washington, USA [10].

The 13,000m2 museum designed by Frank Gehry consists of a sheet metal

façade that was fabricated using cold bending methodology. The roof is

made up of 21 thousand panels of stainless steel with shades of purple,

silver and gold, aluminum and painted red and blue. However, as shown in

Figure 3, the tendency to spring-back and the gaps created around the panel joints due to cold bending are clearly visible.

Case Study

This research utilized Haewoojae as a specimen for

measuring the cold-bending problem. Haewoojae is a toilet museum built

in 2007 in Korea. Shown in Figure 4, the facility is two-story having 418m2 gross floor area, of which glass and aluminum panel façade consists of free-form panels of various curvatures [11].

As planned data

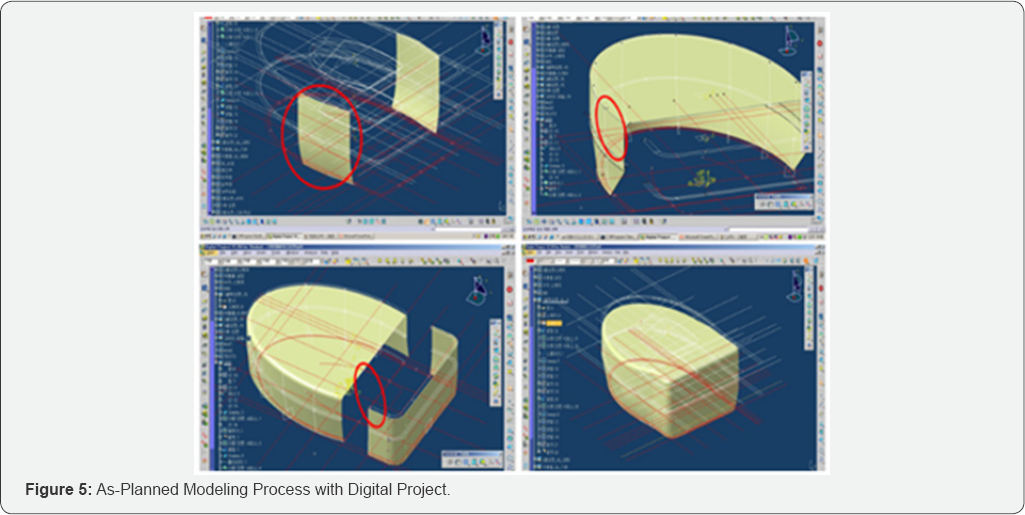

Figure 5

represents Haewoojae modeling results and process with Digital Project

(DP). DP is a commercial software produced by Gehry Technology in 1992

on the basis of CATIA program. Panelization was performed with

rectangular and triangular panel shapes. The basic panel size used in

the modeling was 1m x 1m and smaller ones were applied depending on the

building curvatures configuration.

A total of 533 panels along with 4 different panel

types were identified through panelization: 262 flat panels, 204 single

curvature panels with curvature less than 200mm, 63 single curvature

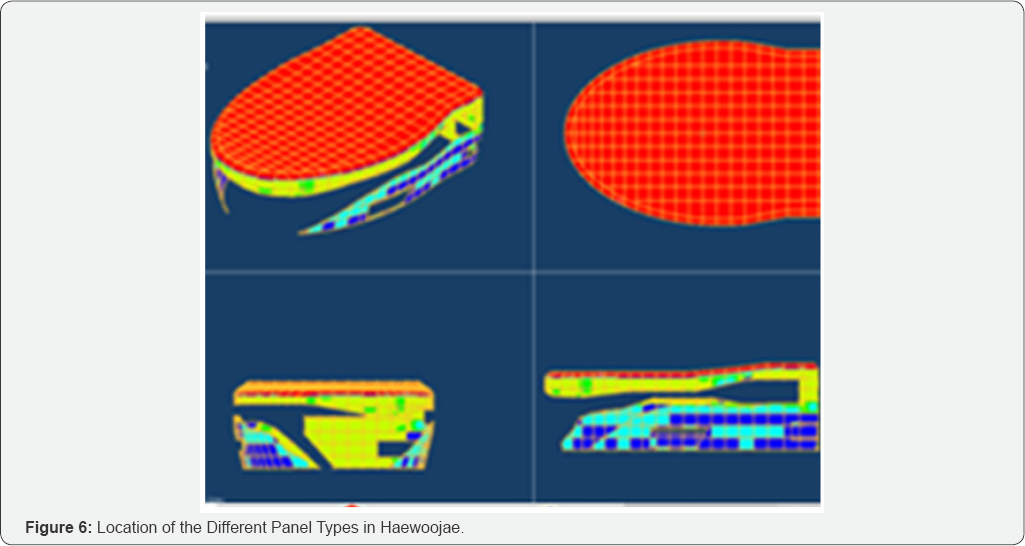

panels with curvature more than 200 mm, and 24 double curvature panels. Figure 6

demonstrates the panel types with different colors: red - flat panels;

blue -single curvature less than 200mm; yellow -single curvature more

than 200mm, and green -double curvature panels.

Panels with large curvature were seen in the 1st and

2nd floor joints, the 2nd floor and roof joints, and the front and rear

curved areas of the building. While it was desirable to produce

the large curvatures panels with computer-based

digital production process for example using CNC machine to secure

after-fabrication aesthetic quality, all of the panels were formed and

fabricated with the cold bending method in the job site by the handymen

using 2D drawings of the facility.

As-built data comparison

3D laser scanning technology was used to obtain

as-built data of Haewoojae. 3D laser scanning is a relatively new

technology that uses light detection and ranging (LIDAR) to extract 3D

accurate representations of objects [12].

It is very similar to radio detection and ranging (RADAR) but the laser

technology utilizes light to measure range or distance instead of

radio.

Since the initial data generated by 3D laser scanning

technology has only the location information represented with point

clouds, the volume elements of a panel is not to be obtained

automatically so that parametric conversion of the data was impossible.

Just like getting the as-planned data of Haewoojae with DP, this study

utilized DP to produce the surface outlines of the scanned facility data

and converted those to BIM parametric data for comparison.

There are several previous research that adapted the 3D scanning technology in the construction industry including Su et al [12], Shin and Huang [13], and Park et al. [14].

The research mostly focused on the procedures and manipulation

techniques of capturing current data of buildings, geotechnical

configurations, and existing infrastructure deterioration conditions as

well as differentiating before and after conditions of certain objects

through a superimposing technique.

Data superimposition comparison

This study utilized the data superimposition method

to identify the differences of the after-construction results, i.e., the

as-built, from the as-planned design of the facility. Comparative

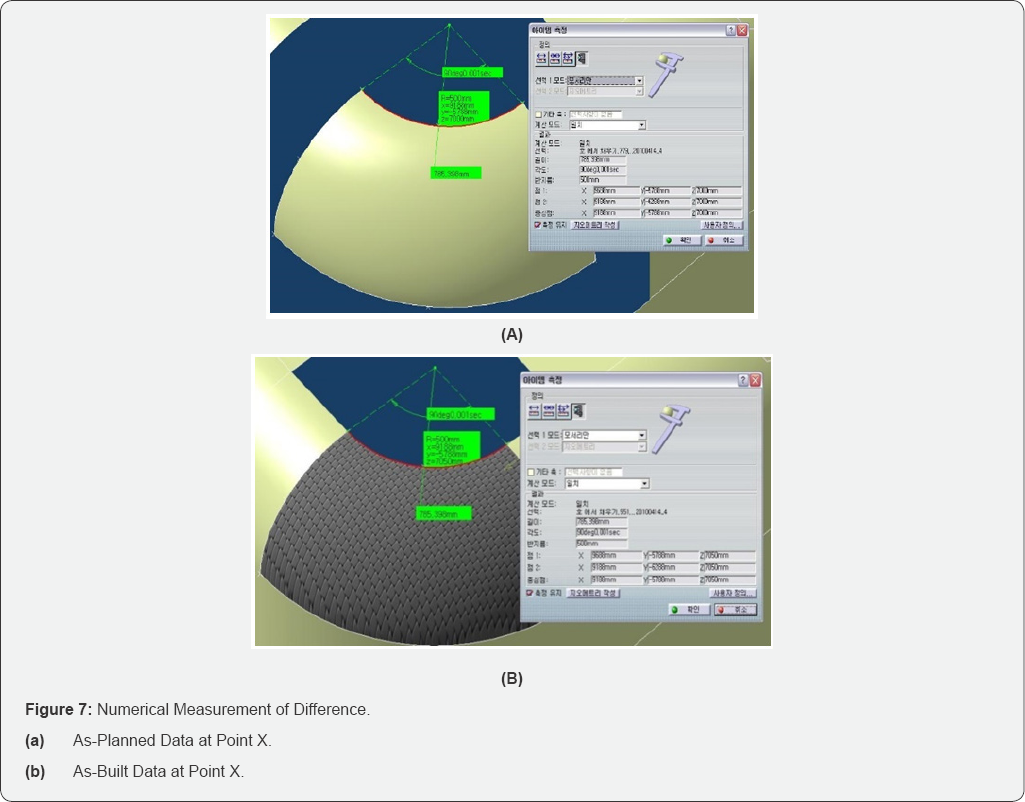

analysis was performed on the five regions of the facility as shown in Figure 7

(i.e., location 1, 2, 3, 4, and 5) with respect to whether the

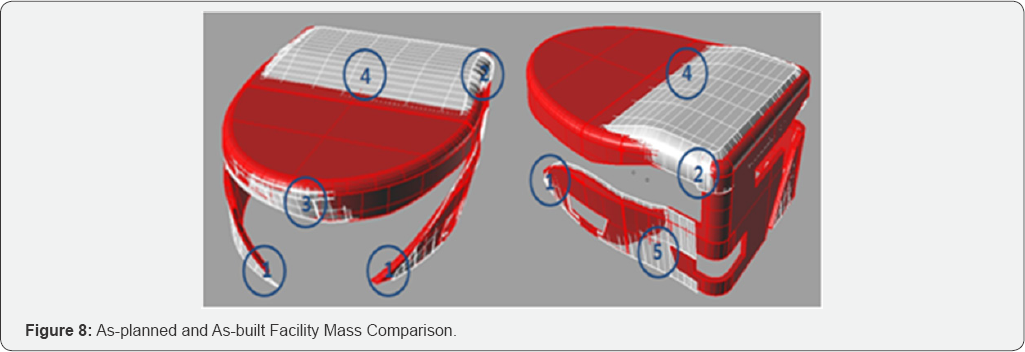

curvatures of the panels in each region are accurately maintained. Figure 8

shows the three-dimensional comparison of the facility mass.

Red-colored areas indicate that the panels in the areas were overall

produced and fabricated as planned. On the contrary, the areas in white

color include the panels of which shapes and curvatures were more or

less different from as-planned.

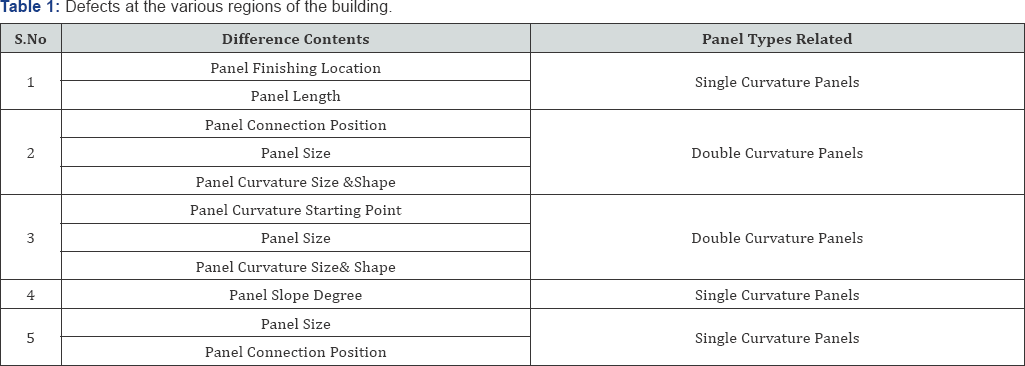

Table 1

summarizes the differences. Discrepant contents in region 1, 4, 5 take

place in the single curvature panels while regions 2 and 3 involve

double curvature panels and their unlike contents show different

features from regions 1, 4, and 5. Based on the superimposition

comparison, it can be inferred that as the curvature gets more complex

and bigger, the panel changes during forming and fabrication become

bigger.

Data quantitative comparison

In order to numerically measure the difference

between the as-built and the as-planned products, spreadsheet

application was performed along with one panel in region 2. Figure 7a & 7b

presents the measurement results delivering the X, Y, and Z-coordinates

of a specific point on the as-planned panel (X,Y,Z = 9188, 5788, 7000)

and the as-built panel (X,Y,Z = 9188, 5788, 7050).

The existence of a 50mm difference at Z coordinate

means that the designated panel at region 2 was constructed 50mm higher

than initially planned, and the panels that are next to the panel also

would be twisted from their original coordinates because of this error.

This twisting may cause lifting of panels and panel joints, water

leakages, and falling off finish materials when fixing the panels to the

main or sub frames [15].

Mock-Up Fabrication

The main objective of this research is to measure

as-built quality of the free-form panels formed and fabricated with the

cold bending method. While the best practice to meet this research

objective is to perform empirical tests using diverse panels through

case studies, there are very few free-form buildings available to test

for cold bending and furthermore, the contractors of the buildings do

not want to use their facilities as case study objects where 3D laser

scanning technology is used to reveal the quality of built outputs.

The authors instead produced mock-up panels by cold

bending. This will help to make the findings from Haewoojae more

reliable and generally viable. The mock-up panels were made with

aluminum and GFRC (Glass Fiber Reinforced Concrete) which were the most

commonly used in free-form buildings in Korea. A total of 8 panels

including one flat panel, two single curvature panels (one with

curvature more than 200mm and the other less), and one double curvature

panel with 800mm x600mm size each other were produced from each

material. During mock-up panel production, 2 experts of each material

were in attendance and advised on the physical properties of the

materials, fabrication, equipment usage, and surface machining methods.

Mock-up production process

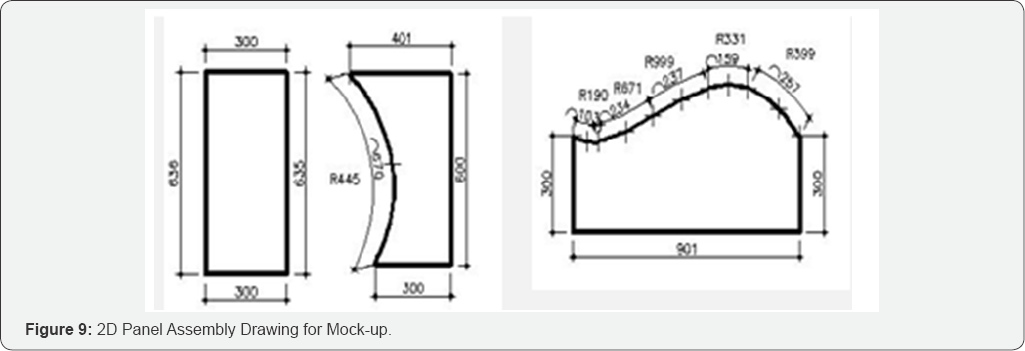

Constructing free-form façade panels with cold bending technique requires 2D fabrication drawings. Figure 9

shows the 2D drawings of the double curvature panel to be used for

producing mock-up panels for this study, which were extracted from the

3D BIM modeling data. The single curvature surface has one curvature

value so that the 2D drawings can be easily defined from the 3D BIM

data. But as for the double curvature surface, points and lines in the

drawings should be approximately drawn with a certain range of error and

close attention needs to be paid during the actual production of the

panels so as to keep the error within that range.

Aluminum mock-up panel production.

Carving, casting to pour, and solidify material are not appropriate for fabricating metal panels [3].

Cutting, roller bending, and pressing are methods generally used to

fabricate curved metal surfaces. In the case of roller bending, the

radius of a curved surface must be more than 200-300 mm. If the radius

is less than 200mm, then press bending is used.

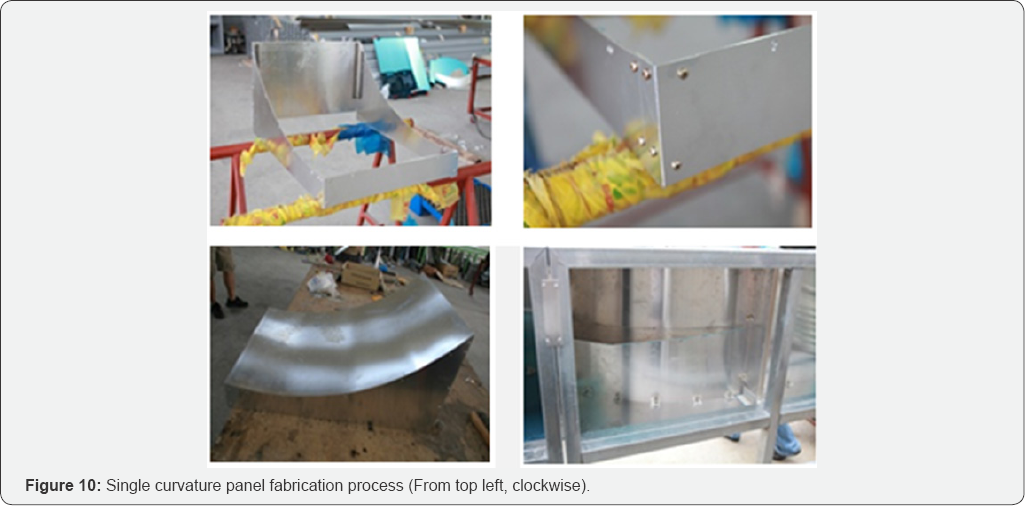

The flat and single curvature mock-up aluminum panels

were produced by roller bending and press bending techniques. During

roller bending, the aluminum sheet was placed between a surface

controlling roller and a fixed roller set with the desired curvature. A

press bending machine pushes and folds a sheet metal panel. Both roller

bending and press bending are typically used to produce a uniformly bent

shape, but are not suitable for creating a bent shape with varying

curvatures or double curvature panels.

When producing the flat and single curvature panels,

the sub-frames were in the first place cut with a CNC machine and the

four sides of a panel were assembled using bolts before fixing a sheet

on top. Figure 10 shows the single curvature panel fabrication process.

Unlike the flat or single curvature panel, the double

curvature panel can be easily flattened by tensile force so that an

intermediate sub-frame was added in the mock-up production. Discussing

with the experts, it was found that the double curved panel with concave

curvature can be fastened to the mainframe by its edge with small

possibility of deformation, but in case of the convex curvature, the

sub-frame was definitely necessary to maintain its curved shape.

The authors tried to form and fabricate the mock-up aluminum double curvature panel with the procedure shown in Figure 10,

but since aluminum could not bear the bending stress, it got destroyed

during fabrication. The panel was so that formed with the combination of

press bending with hammering depending on the panel-forming workers'

proficiency.

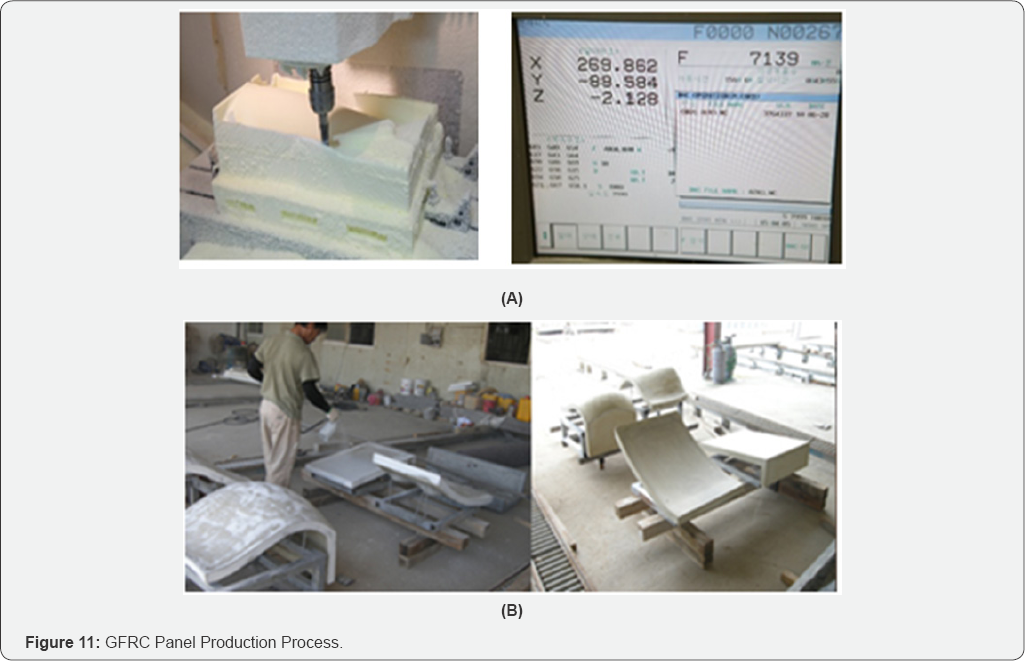

GFRC mock-up panel production

In manufacturing GFRC panels, formwork fabrication is

the most important activity. Since it is not possible to use a

structured formwork for free-form façades such as Euro form, a separate

formwork should be produced and in the first place molds must be made

for producing the formwork. Molds can either be made from wood or

Styrofoam. Styrofoam was used in this study. The mold was produced by

entering its 3D geometric information into a CNC machine, which

automatically produced the mold as shown in Figure 11a.

Having manufactured the mold, the formwork for making

GFRC panels was then produced by pouring concrete into the mold. GFRC

materials were then mixed and poured into the formwork, steam cured for

8-9 hours and then the formwork was taken off from the GFRC panel (See

left picture of Figure 11b). The panel was painted with 2 coats of the desired colors as the final step in the manufacturing of the GFRC panels (Figure 11b).

Mock-up data analysis

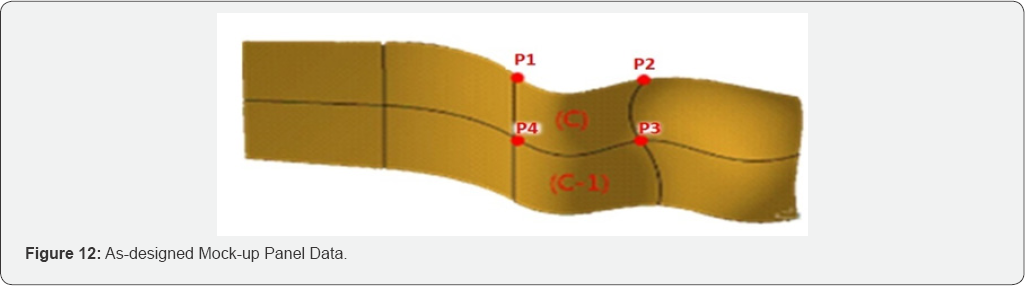

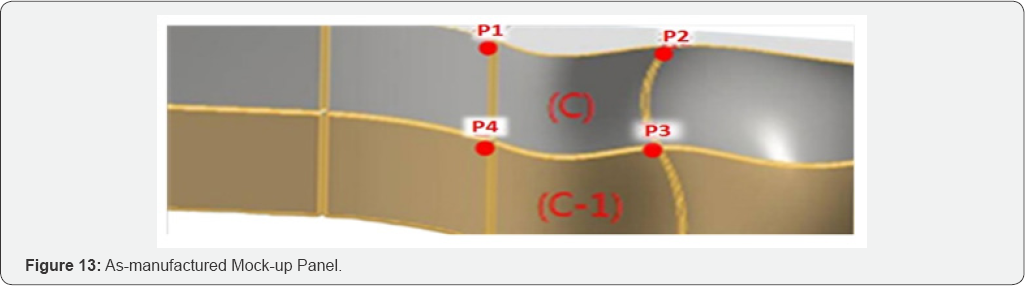

The superimposition method based on 3D laser scanning

technique was used again to compare the as-manufactured with

as-designed mock-up panels. Figure 12 shows as-designed mock- up data while Figure 13 as-manufactured ones respectively. The upper parts of the panel pictures and table data in Figure 12

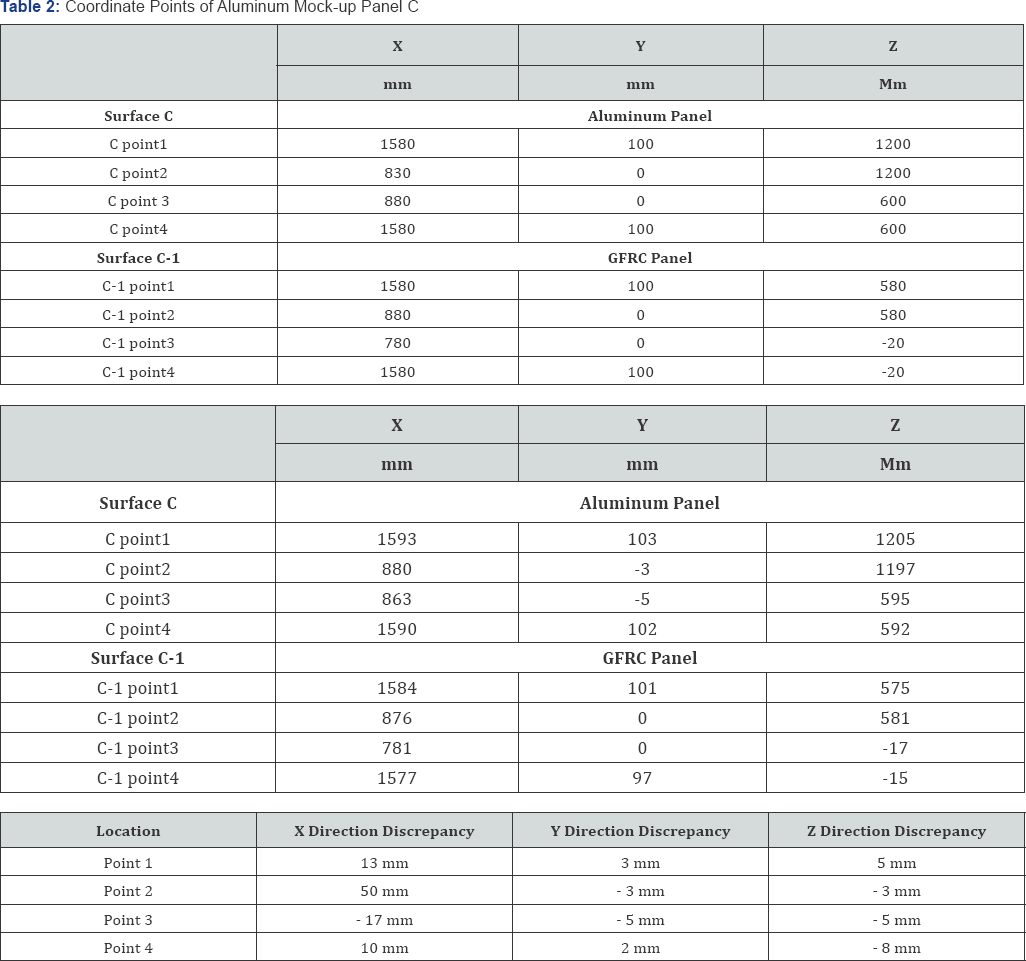

are about 4 aluminum panels and the lower parts 4 GFRC panels. The

first panel shapes in both the upper and lower parts are flat panels,

the second and the forth single curvature panels, and the third double

curvature panel (i.e., (C) on the double curvature aluminum panel, (C-1)

on the double curvature GFRC panel). Figure 13 delivers the same formation of data layout as Figure 12 regarding as-manufactured panel data.

Reviewing the X, Y, and Z coordinates in Figure 12 & 13,

it is understandable that the aluminum mock-up panels demonstrate

bigger discrepancy than the GFRC panels. This tendency can be explained

in conjunction with the material features, so to speak, the spring-back

of aluminum and flexible workability of concrete.

Table 2 summarizes the discrepancy of the as-designed and between point 1 and point 3 was 3cm [2].

This discrepancy was as-manufactured coordinate points of the double

curvature found to exceed the aluminum production allowance provided

aluminum mock-up panel. The length difference between point by the

Korean Industrial Standard in Table 3.

It would therefore pose problems like twisting at the

time of fixing a number of aluminum panels side by side on the

mainframes and sub-frames as designed. This twisting could also lead to

other defects in the long run, such as bulging, water leakages, and

failure of some finishing materials.

Summary & Limit

Through a case study and a mock-up panel fabrication

test, the study demonstrated that cold bending of metal sheets with a

roller or a press seems to have difficulty in meeting the as- planned

shapes of double curvature panels. Although there could be controversy

regarding the worker's level of expertise in handling the panels,

considering the fact that the workers in Haewoojae and the mock-up panel

test have been involved in the architectural façade fabrication field

for more than 10 years and successful in a number of projects, using a

cold bending technique for forming double curvature panels needs careful

technical consideration for securing quality free-form products.

In parallel with proceeding the mock-up test,

interview was conducted with the 4 experts who consulted for the mock-up

test to get an advice on their experience. Referring to the EMP as an

example, they pointed out that cold bending is not suitable for double

curvature panels. While the EMP demonstrated the use of cold bending in

its double curvature panels, only small pieces of sheet metal were used

for double curvatures and for mild curvature panels, large pieces of

sheet metal were utilized to minimize the breaks among the panels.

Despite this design consideration to prevent discontinuity of curvature

due to the breaks from occurring, the breaks made during cold bending

are easily observed.

It was the experts that commented in case where only

cold bending technique is available for free-form façade fabrication, it

is better to design a façade surface having shapes and curvatures that

can be divided into smoothly bent single curvature panels rather than

using complex curved surfaces. As well, it was discussed that providing a

certain range of tolerance in panel joints to the extent where the

visual continuity of curvature among panels is maintained is necessary

to obtain aesthetic free-form products.

While the findings from this study are beneficial to

designers, contractors, and project owners for securing quality

free-form products, there is certain limitation to bring out advanced

inferences for future application due to the limit of case study

materials. As more free-form projects are built in the future, the

authors will perform advanced research to deliver more reliable

findings.

Conclusion

Free-form buildings are known to be difficult to

construct due to their unique shapes and non-conformity to conventional

building techniques. The façade design and installation is considered to

be the most difficult stage in free-form construction. This is because

the facades require cutting edge accuracy in the design, panelization,

optimization, fabrication and installation of façade panels in order to

be delivered as intended by the designer. Therefore ultimate care should

be taken during each of those stages as any mistake could lead to dire

consequences for the project. The choice of material and method of

production of the panels has always been a point of concern for the

free-form design and construction teams. Choice of an unsuitable

material or fabrication method could lead to escalation of costs and

problems during and after installation of the façade panels.

This study focused on cold bending method of

free-form panel manufacturing and installation. Three free-form

buildings namely Haewoojae toilet museum and J museum in Korea, and

Experience Music Project in the United States, whose panels were

fabricated by cold bending were reviewed. The as-built BIM drawings of

Haewoojae were obtained by 3D laser scanning and compared with the

as-planned drawings by the superimposition technique. The results of the

comparison showed that the installed facade panel data deviated from

the originally planned design data.

In order to make the findings more reliable, mock-up

panels made of aluminum and GFRC were designed and fabricated by cold

bending. The panels of each material were of three curvatures types

namely flat, single curved and double curved panels. The flat and single

curved panels' data was found to match. However, the data for the

double curved panels for both aluminum and GFRC was found to have a

certain deviation which exceeded the Korean standard allowance limits.

This would pose problems like twisting at the time of fixing several

aluminum panels side by side on the mainframes and sub frames as

designed for the free-form structure. This twisting could also lead to

other defects in the long run, among others; bulging, leakages, falling

off of some components.

Cold bending was therefore found to be suitable for

manufacture of flat and single curved metal panels. For the case of

double curved panels, cold bending was found to be applicable to a

certain limit of curvature of the panel depending on the expertise of

the manufacturer.

For More Open Access Journals Please Click on: Juniper Publishers

Fore More Articles Please Visit: Civil Engineering Research Journal

Comments

Post a Comment