Finite Element Analysis and Theoretical Study of Punching Shear Strength of Concrete Bridge Decks- Juniper Publishers

Juniper Publishers- journal of Civil Engineering

Abstract

The problem of punching shear usually arises in

reinforced concrete slabs subjected to concentrated loads and

particularly in concrete

bridge decks due to the

development of an internal arching system. Ongoing research revealed

that the governing mode of failure for concrete bridge decks is not

flexure and that using the flexural design method usually led to

unnecessary high levels of steel reinforcement. This paper examines the

applicability of the non-linear finite element formulation of restrained

concrete bridge decks. A special purpose finite element program

FEMPUNCH was developed and employed in this study along with the

commercially available finite element programs. The accuracy of

non-linear finite element analysis is demonstrated using test results

conducted by other researchers. The results of the finite element

analysis are also compared to those obtained from a non-linear mechanics

model developed by Mufti and New hook. The experimental results and the

theoretical model provide insight to the fundamental behaviour of

concrete bridge decks.

Keywords:Polypropylene; FEMPUNCH; Bridge deck slabs

Abbrevations:GFRP:

Glass Fibre Reinforced Polymer; PFRC: Polypropylene Fibre Reinforced

Concrete; CHBDC: Canadian Highway Bridge Design Code; ANACAP: Anatech

Concrete Analysis Program

Introduction

Concrete slab-on-girder bridge decks have been a

popular choice for many short and medium span bridge applications

throughout North America. The authors of this paper have been part of a

Canadian research team, which has been empirically and theoretically

studying the behaviour of these decks for several decades [1,2].

Of principal interest is the strength of these decks under concentrated

wheel loads. This on-going research effort has improved our

understanding of the key mechanisms associated with the strength and

stiffness of these decks and the importance of in-plane restraint in the

performance of concrete bridge deck slabs. Innovative bridge deck

designs have been developed [3] and applied to several highway bridges and other structures in Canada [4] and more recently in the United States.

This paper reports on the theoretical study of the

punching shear behaviour in restrained concrete bridge deck slabs of

girder bridges with emphasis on the analytical comparison of non-linear

finite element analysis and the PUNCH program developed by Mufti &

Newhook [1].

While the design practice is generally to estimate punching shear

strength in concrete using simple empirical equations, these equations

provide little guidance as to the mechanisms involved and the impact of

various parameters on design. The work summarized in this paper helps

identify for the design engineer, the basic behaviour of the system, the

conditions which lead to punching failure and to demonstrate how

non-linear finite element analysis can be adopted to predict the

behaviour of these systems, not just to estimate ultimate load. The

accuracy of the non-linear finite element analysis was demonstrated

using test results available in the literature. The results of the

finite element analysis have also been compared to those obtained from a

mechanics model developed by the authors.

Externally Restrained (Steel-Free) Concrete Bridge Deck Concept An externally

An externally restrained steel-free concrete bridge deck slab [2]

consists of providing a system of steel straps between adjacent girders

to restrain any lateral movement of these girders. All internal

reinforcement can be removed; internal glass fibre reinforced polymer

(GFRP) crack control reinforcement may be added if desired [3].

Research has also shown that the bottom transverse reinforcing bars act

as ties for this same arching action mechanism rather than as flexural

reinforcement for the perceived moments [5]. Deck slabs with internal reinforcement of either steel or FRP [3]

are therefore considered to be internally restrained deck slabs. Under

concentrated wheel loads, the restraining elements develop increasing

tensile stresses and provide a lateral restraining force to the concrete

deck slab. As a result, compressive membrane forces within the deck

slab are developed. The degree of lateral restraint provided will

determine the ultimate load at which the deck fails in punching under

concentrated loads such as vehicle wheel loads.

Response of concrete deck slabs to wheel loads

Extensive field and laboratory testing on concrete

deck slabs subjected to wheel loads indicates that two structural

responses occur. The initial response is primarily flexure, which leads

to the formation of longitudinal cracks on the underside of the deck

between adjacent girders. After the formation of the first longitudinal

crack, however, compressive membrane action or arching also forms a

component of the response mechanism. If sufficient lateral restraint

exists, then the arching response will dominate the latter stages of the

loading behaviour and failure will occur through punching of the deck

slab.

The punching failure of restrained reinforced concrete slabs had been documented as early as the 1960s by Taylor & Hayes [6] and investigated specifically as it relates to bridge deck behaviour in the 1970s by Hewitt & Batchelor [7].

In these and other works, the focus was on the enhancement that arching

behaviour provided to reinforced concrete systems. The steelfree deck

slab evolved from the philosophy of using the arching behaviour as the

primary resistance mechanism. This approach necessitated the enhancement

of internal arching forces through a clear and quantifiable in-plane

lateral restraint system in both the longitudinal and transverse

directions. This restraint is provided by two elements. Firstly, the

slab is made composite with the supporting girders, either steel or

prestressed concrete. In the longitudinal direction, the large axial

stiffness of the girders provides in-plane restraint. Secondly, in the

transverse direction, the required restraint is achieved through the

addition of external steel straps, normally 25x50mm in cross-section and

spaced at 1200mm, which inhibit the relative lateral displacement of

adjacent girders. With compression as the dominant mechanism, all

internal reinforcement can be removed. Further design details can be

found in the design clauses of CHBDC [3] and a recent report of the American Concrete Institute [8]. The essential elements of the system are shown in Figure 1.

In early research, this system was often referred to

as a fibre reinforced concrete (FRC) or polypropylene fibre reinforced

concrete (PFRC) deck slab due to the use of short randomly distributed

synthetic fibres to control plastic shrinkage cracking. In later work,

it was referred to as steel-free concrete deck slabs or corrosion-free

concrete deck slabs. In the most recent version of the Canadian Highway

Bridge Design Code (CHBDC) [3],

it is referred to as externally restrained concrete bridge deck slabs.

In reporting the research in the following sections, these historical

designations have been maintained.

Mechanics Model for Punching Shear Strength

To help develop a reliable theoretical tool for the

analysis of bridge decks, the authors re-examined the physical

observations made during the experimental program on a variety of

steel-free deck models. A more extensive literature review also turned

up many similarities between the experimental column punching tests

conducted by Kinnunen & Nylander [9].

Kinnunen and Nylander had also proposed an empirical failure criteria

based on concrete strains close to the punching zone (referred to herein

as K&N failure criteria). Using test observations and the K&N

failure criteria, a mechanics model of the behaviour was developed and

refined to address additional unique aspects of the externally

restrained bridge deck slabs under wheel loads.

Mechanics model formulation

The important components of the system geometry are

the depth of the concrete deck, the spacing of the support girders, the

spacing and the cross section area of the transverse straps and the

dimensions of the loaded area. The essential material parameters are the

modulus of elasticity of the material of the transverse straps, the

yield strain of the straps, the compressive strength of the concrete,

and the 3-dimensional effect on the compressive strength of the concrete

under confined conditions.

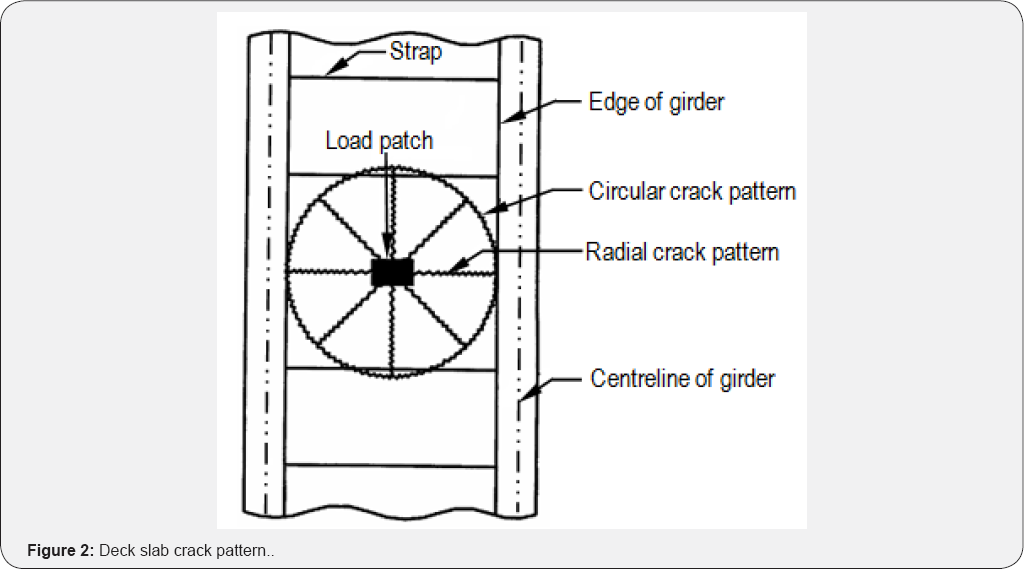

During the initial loading phase, a concrete slab

subjected to a concentrated load forms radial cracks on the bottom

surface of the slab originating below the load point. As the load

increases, these cracks gradually migrate to the top surface of the slab

to become full depth cracks (Figure 2).

On the top surface of the slab, circular cracks form at a diameter

approximately equal to the clear spacing between the girder flanges. As

the failure load approaches, an inclined shear crack develops,

originating on the bottom of the slab at some distance away from the

load point, in a circumferential manner. At punching failure, this

inclined crack forms the upper surface of the punch cone. The sections

of concrete outside the shear crack can be divided into wedges bound by

the shear crack, the radial cracks, and the outside edge of the slab.

Under further loading, these wedges act as rigid bodies in the radial

direction and rotate about a centre of rotation (Figure 2 & 3).

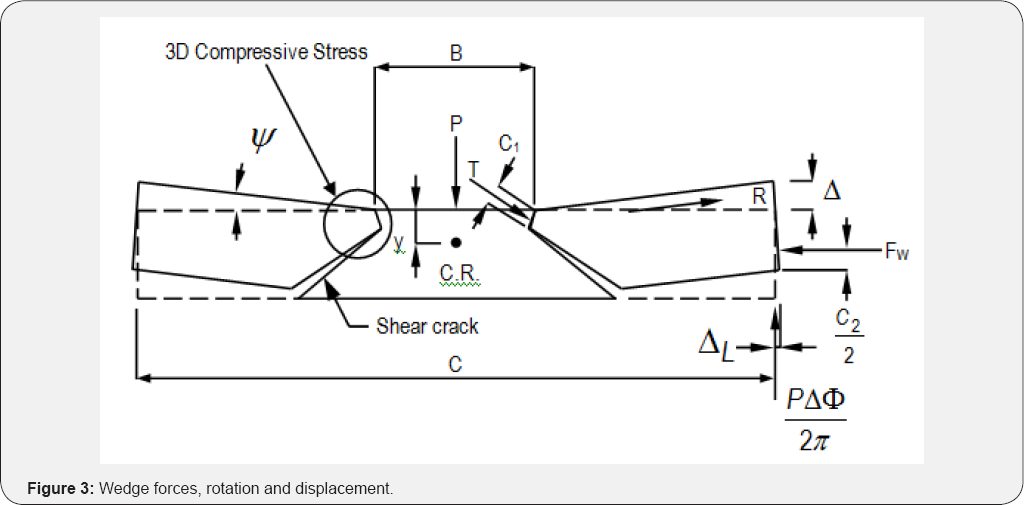

As a wedge shown in Figure 3

rotates through an angle , it has an associated lateral displacement L

which is restrained by the stiffness of the straps. If we designate K as

the stiffness of the strap, in units of force/displacement per unit

length of circumference, then the restraining force is calculated as K

L. If we consider a single wedge component, then the forces acting on

this wedge are an oblique compressive force acting through the

compressive shell and supporting the loaded area T; the vertical support

component P Δ Φ /2 Π ; the lateral restraining force

for the wedge Fw; and a circumferential force R that is developed as the

wedge rotates through . The circumferential force R is maximum at the

edge of the loaded area. Considering these forces acting in combination

with the horizontal component of T and the vertical stress from the

applied load, the region near the loaded area is in a state of triaxial

compressive stress with σ 1 ≤ σ2 ≤ σ 3 and σ3 = a r’σ 2 = σθ and σ 1 = σ

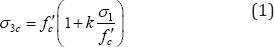

v. Equation 1 is used to model the behaviour of concrete under

confinement which enables σ3 to be expressed in terms of 1. As long as

the three dimensional state of confinement is maintained around the

loaded area, the concrete capacity will remain very high.

Where, k is a confinement factor (based on comparisons with the experimental punching program, Newhook [10] determined that a value of k=10 was appropriate for the bridge deck application).

Employing the equilibrium conditions and

relationships described above, the forces and displacement can be

resolved for a given value of applied load P. A complete description of

this mathematical formulation is found in Newhook [10]. In addressing the similar problem of the punching of a column slab connection, K & N [9]

established empirical criteria for punching failure which was adopted

by the authors for bridge deck slab punching. When the circumferential

strain at the top surface of the slab close to the loaded area reaches a

critical value, ϵ ct =0.0019, failure occurs. This value

corresponds to the value of strain at the maximum uniaxial compressive

stress fc, and the commonly used value of ϵ ct =0.002 is

adopted. While K&N merely reported this value as an empirical

observation, the authors propose that this criterion also corresponds

well with the importance of the 3-dimensional confinement of the

concrete surrounding the loaded area. Once ϵ t equals 0.002,

the concrete response softens in that direction leading to a reduction

in the confining force, hence punching failure.

The authors also proposed a second parameter that is

also capable of initiating punching failure. The lateral restraint is

provided by transverse steel straps. The stress in the straps increases

with applied load. It is possible that the stress in the straps reaches

the yield stress of steel before failure of the concrete occurs. Once

the strap yields, it can no longer provide increasing restraint force

and hence the concrete will punch under a slight increase in applied

loading.

Comparison with experimental work

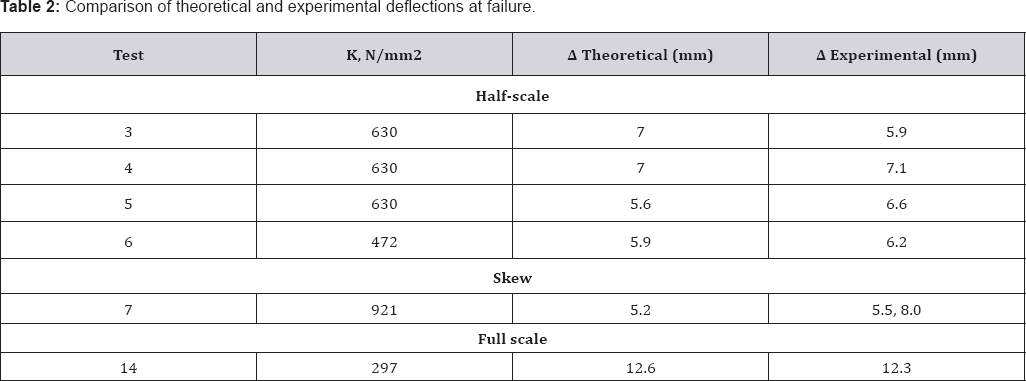

Comparisons were conducted between experimental failure loads and those predicted by the mechanics model Newhook & Mufti [1]. A partial listing of those comparisons is presented in Table 1.

Comparisons of the theoretical and experimental load- deflection and

load strap strain results also showed very close agreement [10].

The theoretical model was used to analyze three half-scale tests reported by Mufti et al. [2] and Newhook [10], a deck test on a skew bridge reported by Bakht & Agarwal [11] and full scale testing reported by Thorburn & Mufti [12] and Newhook & Mufti [13].

The experimental deck slabs failed in punching shear and a comparison

of theoretical versus experimental failure load is presented in Table 1.

The comparison reveals that the mathematical model can predict within

reasonable accuracy the punching failure load of internally restrained

bridge deck slabs (Figure 4).

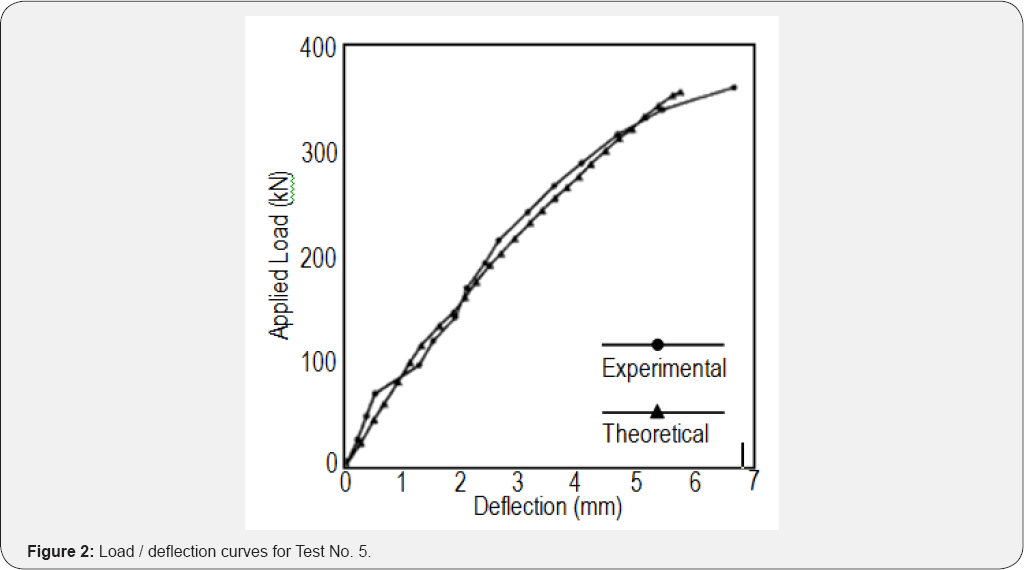

Using the procedure described above, a load deflection curve is constructed for half scale Test No. 5 from Table 1.

A small slab displacement is assumed and the associated value of

applied is load determined along with strap strain and concrete strain

values. If the failure condition is not satisfied, an increment of

deflection is assumed and new values determined Newhook [10,14].

This process is repeated until a failure condition is met. Using the

values of displacement and load, the theoretical curve shown in Figure 4

is produced. While the experimental curve the theoretical curve though

smooth is in good agreement with the observed deflections. The model is

reliable in predicting the order of the magnitude of deflection. The

experimental deck deflections at ultimate for the tests in Table 1 are compared with theoretical deflections in Table 2. The comparison reveals very close correlation providing further support for the validity of the mechanics model(Table 2)

Based on the successful development of this model,

the following parameters were confirmed as necessary to properly predict

the bridge deck behaviour under wheel load including prediction of

ultimate load: deck thickness, girder spacing, strap geometry (restraint

stiffness), concrete strength and strap modulus. In addition, strain

limits in the strap material and the concrete could be used to define

ultimate limit state.

Non-Linear Finite Element Modelling Studies

The initial investigation of externally reinforced bridge deck behaviour was conducted by Wegner and Mufti [15] who attempted to use finite element modelling to replicate the behaviour of the experimental model [2] listed as Test 3 and 4 in Table 1.

The commercially available program ADINA (ADINA R&D Inc. 1987) was

chosen, since it incorporated a sophisticated tri-axial material model

for plain concrete. Specifics of the model and analysis details are

reported elsewhere [15,16].

While Wegner and Mufti were able to model the behaviour of one specific

test, they concluded that this early finite element modelling attempt

was very sensitive to a number of parameters and that extensive

calibration with known results and modelling iterations would be

required to fine-tune the numerical procedures for a particular

application.

The Wegner and Mufti finite element study was

conducted prior to the development of the analytical model described in

Section 3. This model indicated clearly that for a commercial program to

be used successfully the K&N strain limit failure criteria must be

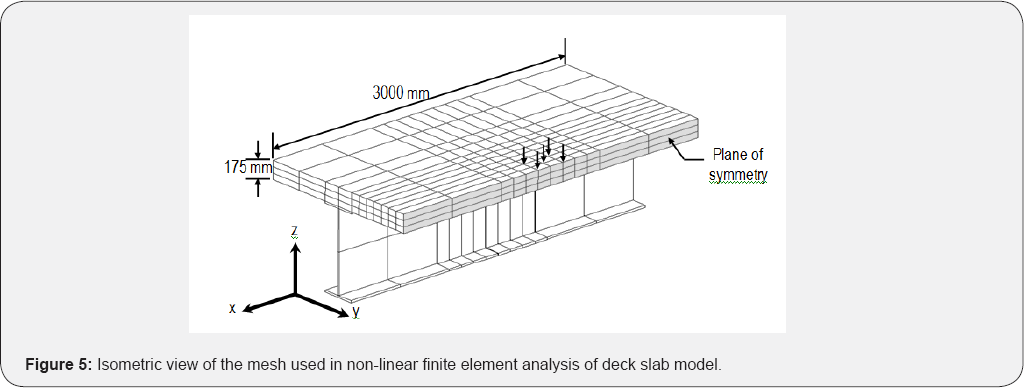

used. Hassan et al. [17]

conducted finite element analysis of an internally restrained concrete

bridge deck slab subjected to wheel loads using the "Anatech Concrete

Analysis Program" (ANACAP, Version 2.1) and defining failure as the load

at which the K&N failure criteria is met. One-half of a bridge deck

slab was modelled using 20-node brick elements. The slab thickness was

divided into three layers. The mesh dimensions used in modeling the deck

slab are given in Figure 5.

The reinforcement was modelled as individual sub-elements within the

concrete elements. Rebar sub-element stiffnesses were superimposed on

the concrete element stiffness in which the rebar resides. A complete

description of the modeling can be found in Hassan et al. [17] (Figure 5).

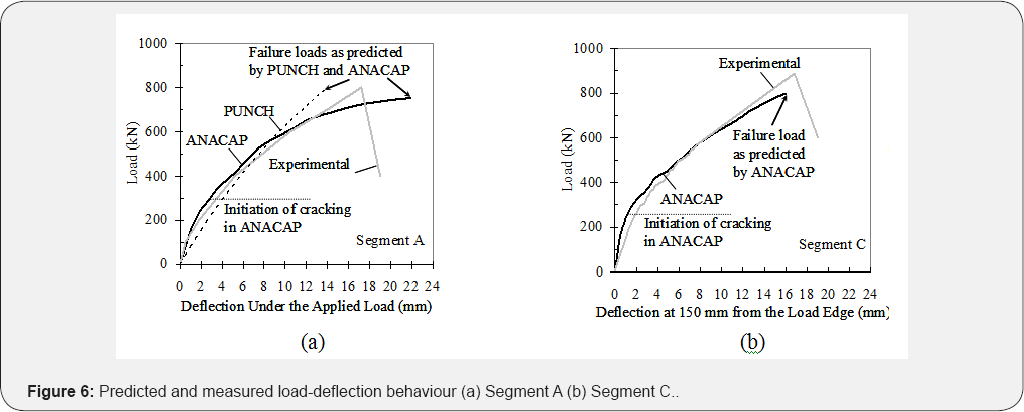

Hassan et al. [17]

modeled the punching behaviour of a full- scale experimental model of a

concrete deck slab on two steel girders tested by Khanna et al. [5].

The experimental model had four segments (Segments A through D) in

which the internal reinforcement configuration was varied. Segment A had

a top and bottom grid of orthogonal reinforcement, typical of current

design practice, and Segment C had just bottom transverse bars. The

comparison of the ANACAP theoretical results with the experimental

load-deflection results for these two segments are presented in Figure 6a and 6b,

respectively. For failure prediction, use of the K&N criteria was

critical. With this failure modeling approach, the FEM model proved to

be far more robust than the model used previously by Wegner & Mufti [14].

Furthermore, the study confirmed that the presence of top reinforcement

in bridge deck slabs has a negligible effect on punching shear capacity

(Figure 6a & 6b).

Specialized Non-Linear Fem For Bridge Deck Slabs - Fempunch

The successful use of the K&N failure criteria

with a commercial FEM program led to the development of a specialized

FEM program for non-linear analysis of externally restrained concrete

slab on girder bridges, FEMPUNCH. The program has several features which

facilitate the pre-processing and input of bridge geometry. It permits

the input of values for the lateral restraint of the straps and includes

an orthotropic material model for concrete as well as permits concrete

cracking and strain softening and models the benefits of 3-dimensional

confinement. It includes the limiting strain proposed by K&N as the

failure criteria. The concrete is modelled using a 20-node isoparamteric

brick element and the girders are modelled using 2-dimensional beam

elements.

FEMPUNCH theory and program

Complete details on modeling assumptions and parameters can be found in Desai et al. [18].

The following assumptions and simplifications have been incorporated into FEMPUNCH:

I. The stiffness of straps is smeared across the length of the girders.

II. Lateral stiffness of the supporting girders is considered to be uniform across the length of the girder.

III. The girders are unyielding in the vertical direction, a simplification that can be remedied easily.

IV. Concrete is modelled as an orthotropic material

with the direction of orthotropy being defined by the principal stress

directions.

V. Cracking can occur in three orthogonal directions at an integration point used in the formation of finite element equations.

VI. If cracking occurs at an integration point, it is

modelled through an adjustment of material properties by considering

cracking as a smeared band of cracks.

VII. Strain softening occurs from compression crushing failure to the ultimate strain, at which the concrete fails completely.

VIII. The tensile cracking failure and the concrete crushing failures occur along the principal direction

IX. Load increases monotonically, leading to failure

An isoparametric, 20-node solid brick element has

been used in the program to model a bridge deck. At each node, three

translational degrees of freedom (u, v and w) are considered. Details of

the shape functions and formulation of element level matrices can be

found in the literature.

Only one element has been considered in the thickness

direction on the basis of the finite element work done by Wegner &

Mufti [15].

On the other hand, the number of elements in the longitudinal and the

transverse direction is chosen such that the aspect ratio is nearly one.

On the basis of the average thickness, the program would select the

number of elements automatically between two adjacent sections. However,

a user can override this option and feedin the information explicitly.

Modelling of concrete

The 3-dimensional constitutive relations for concrete

have been derived from an equivalent, uniaxial constitutive relation,

which can be determined experimentally. The uniaxial stress- strain

curve has been employed in the program to calculate the tangent modulus.

The stress-strain curve for the concrete has been described by the Saenz's equation [18].

While other 3-dimensional concrete models exist, Saenz's model was

selected as it was found to be easier to program and provided equally

accurate results. It also avoided singularity problems in the solution

process encountered by Wegner & Mufti [15].

Modelling of crack

Tensile failure would occur in concrete when the tensile stress in the principal direction exceeds the tensile strength, a f, of concrete. The presence of a crack at an integration point is modelled by modifying the constitutive matrix [18]. When a crack forms, the normal as well as the shear stiffnesses reduce. Consider for illustration that σp1 exceeds σf.

Solution procedure

The ensuing system level equations are solved in the

Lagrangian coordinate system using Newton-Raphson procedure. In-core

solution technique has been used to expedite computations. The loads are

applied incrementally and iterations are performed per load increment

until the solution converges. The incremental displacements and stresses

areadded to the values from previous load increments to get the total

displacements and stresses. The numerical solution iscontinued until

failure occurs.

Comparison with internally restrained deck slab results

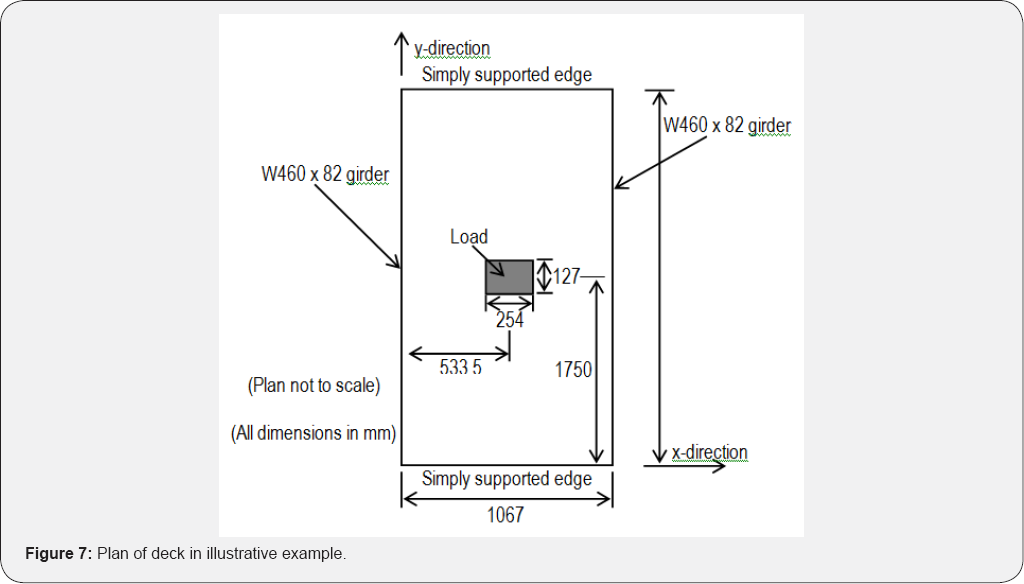

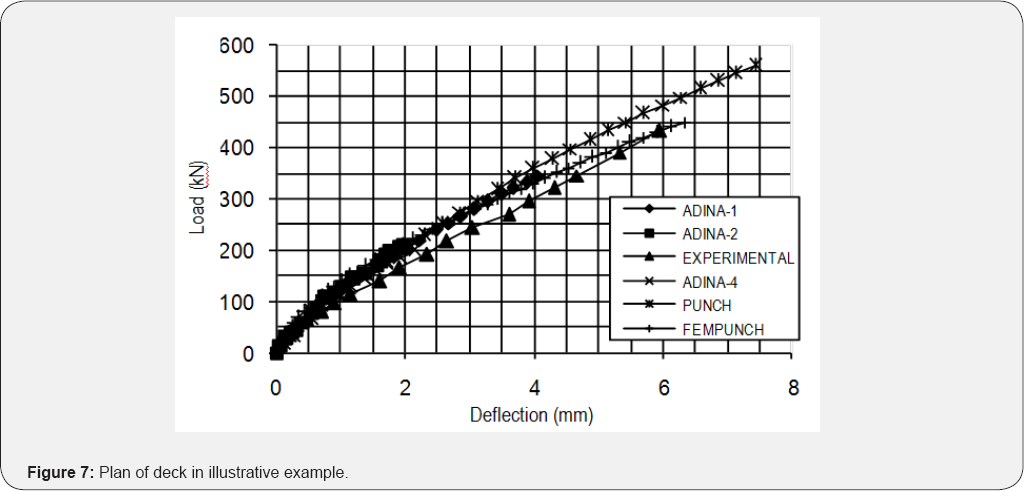

The internally restrained deck slab considered by Wegner & Mufti [15] (Figure 7)

has been analyzed using program FEMPUNCH. The load versus deflection

under the wheel load results obtained from program FEMPUNCH have been

compared with the experimental data, as well as results from the ADINA

analyses and results from program PUNCH [14]. It can be seen in Figure 8 that the results from program FEMPUNCH match reasonably well with the experimental data at failure (Figure 7 & 8).

This specialized finite element program incorporates

behaviour characteristics and failure criteria developed in the

analytical model of Section 3, it also provides several key

improvements:

a) Both right bridges and skew bridges can be analyzed;

b) The stiffness of the bridge girders can be modelled;

c) The influence of the global stiffness of the concrete deck outside the punch zone can be included; and

d) The influence of the wheel position relative to the planar geometry of the deck can be modelled.

Further investigations by Klowak et al. [19] demonstrated that the FEMPUNCH program can also be used to predict the response of deck cantilevers to wheel loads.

Conclusion

This paper presents a brief overview of the authors'

investigations into modeling the non-linear behaviour and failure of

concrete slab on girder bridges to supplement the extensive experimental

work in this area. Analytical and specialized finite element tools have

been presented. In developing these models, the use of the K&N

failure criteria was a key consideration in achieving correlation with

experimental results. Both models also allow for the development of a

load versus deflection curve for the entire loading not just a

prediction of ultimate load. Hence the models, and in particular the

finite element, will permit engineers to study the impact of various

geometry and material parameters on the behaviour of the deck system.

These parameters, in general order of greatest impact on ultimate load,

are:

a. Stiffness of the external restraint to the deck including straps and girders;

b. Deck thickness;

c. Girder spacing;

d. Strap material properties; and

e. Concrete strength.

The modeling work also shows that the punching

strength of the concrete deck slab cannot be considered a function of

just the concrete slab thickness and compressive strength alone but is a

property of the entire deck system including the girders and any other

means of lateral restraint, in the case external straps.

The punching strength of a concrete slab on girder

bridge deck subjected to wheel loads represents a complex problem

including both material and geometric non-linearities. To date, no

simplified formula has been able to capture the impact of all the

parameters discussed in this paper. It is believed that the research

presented in this paper will be of assistance to engineers seeking to

implement more rigorous solutions and to better understand the

influenceof their design choices on the performance of this bridge deck

system.

Acknowledgement

The authors acknowledge the contributions to modeling

and understanding bridge deck behaviour by the many graduate students

and research assistants whose published work is cited herein. The

authors also acknowledge the long standing collaboration with our

colleague Dr. Baidar Bakht who initially requested that we develop a

theoretical model to help understand the behaviour observed during

experimental work and who has continued to participate in the solutions.

For More Open Access Journals Please Click on: Juniper Publishers

Fore More Articles Please Visit: Civil Engineering Research Journal

Fore More Articles Please Visit: Civil Engineering Research Journal

Comments

Post a Comment