Effect of Sand Fines and Water/Cement Ratio on Concrete Properties- Juniper Publishers

Juniper Publishers- Journal of Civil Engineering

Abstract

Sand fines (clay/silt) and water/cement ratio have

been reported to be one of the causes of weakness in concrete strength. A

study was conducted to determine the effect of fines content in sand

and water/cement ratio on some properties of concrete. Fines content in

sand of 2%,

4%, 6%, 8%, 10% and 12% as well as water/cement ratio of 0.55, 0.6 and

0.7 were used. The concrete were prepared using the basic mix 1:2:4.

Workability test on flesh concrete as well as compression and split

tensile strengths were conducted in accordance with BS 1881. The results

show that, workability of concrete decreased as fines content

increases. At the same level of fines content, workability increases

when the W/C increased. The study again revealed that up to 4% fines

content, compressive strength increased as the fines content increases.

There was a decreased in the compressive strength with increased in all

W/C. The same trend was found for the tensile splitting strength

results. Predicting the effect of fines and W/C on work ability and

strengths of concrete using regression analysis suggest that, over 80%

of the variation in the workability and strengths were influenced by

fines and W/C. It was concluded from the study that, fines content of 4%

in sand and water/cement ratio of 0.55 is appropriate for concrete for

structural use.

Keywords: Sand Fines; Water/cement Ratio; Workability; Strength; Concrete

Abbreviations: BS: British Standards; ASTM: American Standard for Testing and Materials

Introduction

Concrete is a very important material in the

construction industry which is spearheading infrastructural development

in Ghana leading to the expected prosperity and growth of the nation.

The quality of concrete constituent materials controls its strength [1] which has also been found to be one of the causes of building collapse all over the world [2-4]. For this reason attention must be given to the factors which affect the strength of concrete [5-7].

Among these factors are sand fines which are

materials that passes through the 75μm sieve. These fines are considered

as an impurity in building sand in the BS882:1992 [8]. The presence of sand fines in concrete is likely to affect the workability, strength and long-term performance of concrete [9].

To this effect, the percentage limit of sand fines (clay/silt) is

recommended by various building standards in other to check their

effects on the strength of concrete. Some of which are the British

Standards (BS), and the American Standard for Testing and Materials

(ASTM) which recommends 4% and 10% of fines in building sand

respectively. Nonetheless, Ghana is yet to specify the limit of fines

(clay/silt) percentage in building sand for producing concrete.

Moreover, it has been recommended by Danso and Boateng [10] to investigate the quality of building sand used in the Ghanaian construction industry which is yet to be realized.

Another contributing factor affecting concrete

strength is the water content used which in some cases are increased to

improve workability [11,12].

When the fines content in sand are excessive, there is the need to add

more water to the concrete mix in other to improve the workability. That

is fine particles such as clay and cement interact with water in a

physiochemical state which leads to more absorption of water than that

of fine and coarse aggregates. Research have shown that higher amount of

sand fines in concrete results in poor workability. This eventually

leads to the addition of water to the concrete mix before or even during

the unloading process to improve workability [12].

Meanwhile, research have also shown that an increase

in water/cement ratio result to a decrease in the compressive strength

of concrete [13,14].

Additionally, the increase in sand fines content has also been found to

decrease the compressive and tensile strengths of concrete [15,16].

Inadequate sand fine content also has adverse effect of the strength of

concrete due to poor adhesion. Researchers have therefore develop

various models for predicting the effect of sand fines and W/C on the

strength of concrete. However, there is a gap in literature for the

combined effect of sand fines and water/cement ratio's effect on the

properties of concrete. This paper seeks to address this gap in

literature.

Materials and Methods

Materials

The materials used were crushed granite as coarse

aggregate, natural pit sand, ordinary Portland cement and water.

Physical properties of the aggregates were analysed. These properties

included the specific gravity, water absorption, fineness modulus,

surface texture, particle shape and colour. The specific gravity and

water absorption were conducted in accordance with the ASTM C128:1997

for fine aggregate and ASTM C127:2007 for coarse aggregate.

Testing methods and procedures

Sample size: A total of 216 specimens were

cast for strength testing. Out of this, 162 were made of 150mm cubes for

compressive strength testing at 7, 28 and 91 days curing whereas 54

were made of 150x300mm cylinders for splitting tensile strength testing.

The number of concrete batches prepared was 18 containing the various

sand fines (clay/silt) replacement in the fine aggregate with three

different water/cement ratios.

Mixing of concrete: Fines (clay/silt) were initially extracted from sand using dry sieving (Figure 1).

During this stage, the sand was first spread and dried in air for some

days and sieved with the 600μm sieve. Sand passing through the 600μm was

further sieved with the 75μm sieve where the sand particles passing

through this sieve were collected for replacement of the sand content in

concrete. The sand particles retained on the 75μm sieve were gathered,

washed with water to remove left over fines and dried by spreading in

air for 7 days.

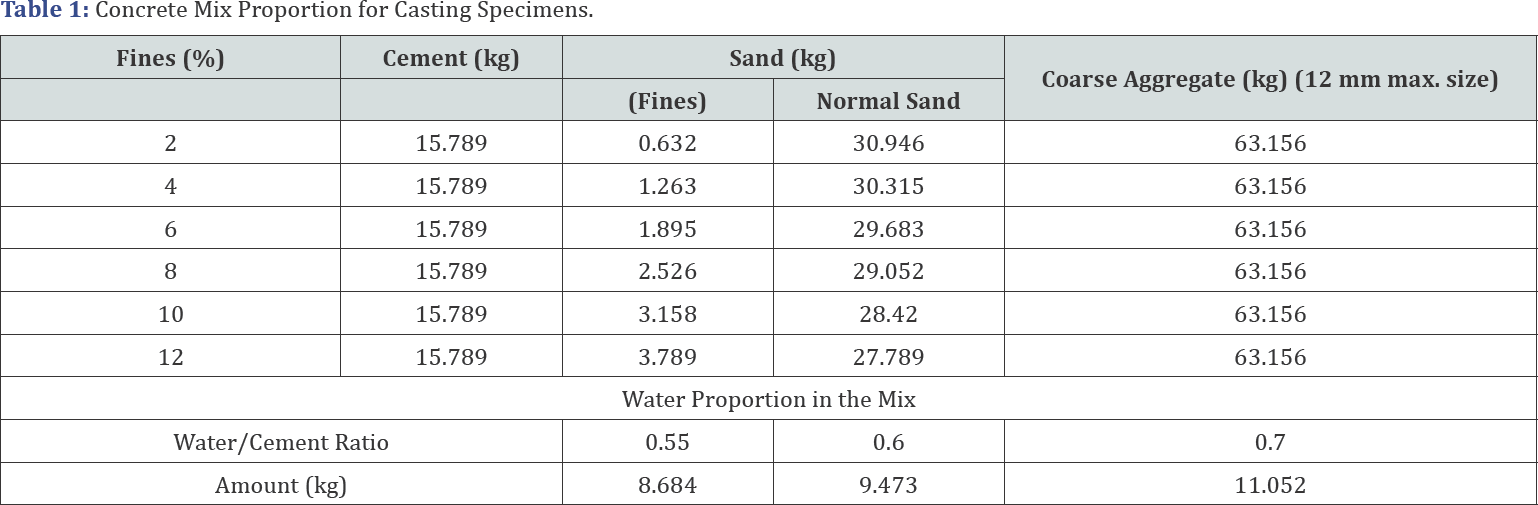

The amount of various materials needed for each mix

proportion which could cast 9 cubes and 3 cylinders were batched for

concrete mixing (Table 1).

Different batches of concrete consisting sand with fines content of 2%,

4%, 6%, 8%, 10% and 12% with three constant water/cement ratios of

0.55, 0.60 and 0.70 were prepared for the study. The amounts of coarse

aggregate used were kept constant for all batches. The concrete were

mixed using 1m3 drum concrete mixer.

Workability test: Slump measurement was taken immediately after mixing each batch of concrete before casting them into specimen moulds (Figure 2).

The moulds were coated with oil just before concrete casting. The

concrete were cast in three layers into the moulds and each layer was

tamped 25 times with 16mm diameter rod to removed entrapped airs present

in the concrete. Excess concrete were cut away and the surface levelled

with the trowel.

Curing of specimens: The specimens were

initially cured in air for 24 hours. The moulds were then removed and

were then immersed into water in a curing tank for 7, 28 and 91 days.

Strength testing: Cube specimens for compressive strength test were conducted in accordance with the BS EN 123903 [17].

The cube specimens were inserted into a universal testing machine of

which the surface of the cubes were aligned perpendicularly to the

platens. An automatic loading rate within the range of 0.04MPa/s to

0.06MPa/s was applied to the specimen until failure occurred (Figure 3). The capacity of the testing machine was 2000kN maximum loading.

The cylindrical specimens for splitting tensile strength test were conducted in accordance with the BS EN 12390-6 [18].

A diametrical compressive force was applied on the cylindrical

specimens placed centrally with its axis horizontal between the platens

of the universal testing machine. The specimen was supported in a jig

with plywood used as parking strips conforming to EN 316. An automatic

constant rate of loading within the range of 0.04MPa/s to 0.06MPa/s was

applied without shock which increased continuously until splitting of

specimen occurred (Figure 4).

Results and Discussion

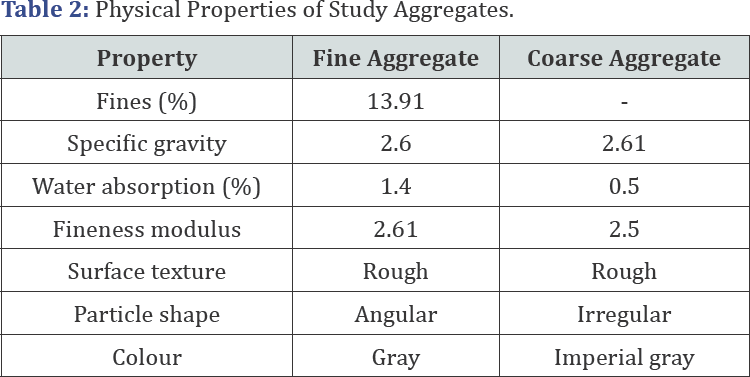

Physical properties of aggregates

Table 2

gives the physical properties of the aggregates that were used for the

study. The specific gravity of saturated surface-dry samples measured

were 2.60 and 2.61 for fine and coarse aggregates respectively. This

indicates the aggregates used for the study were within the accepted

specified values for concrete production in accordance with BS EN 1097-6

[19].

The water absorption for the sand used was 1.4% which is below the

specification limit of 2%. This explains that, much of the water used

for mixing the concrete will be absorbed by the aggregate to keep it at

the saturated surface dry state and the rest for mixing the concrete and

hydration of cement. The water absorption of coarse aggregate was 0.5%

which was within the normal range from0.1 to 0.6%.The fineness modulus

obtained suggest that, the aggregates used had an approximately average

sizes of 600μm and 12.5mm for fine and coarse aggregates respectively.

Thus, the sand used was normal sand since it lies within Zone II of

geological grading.

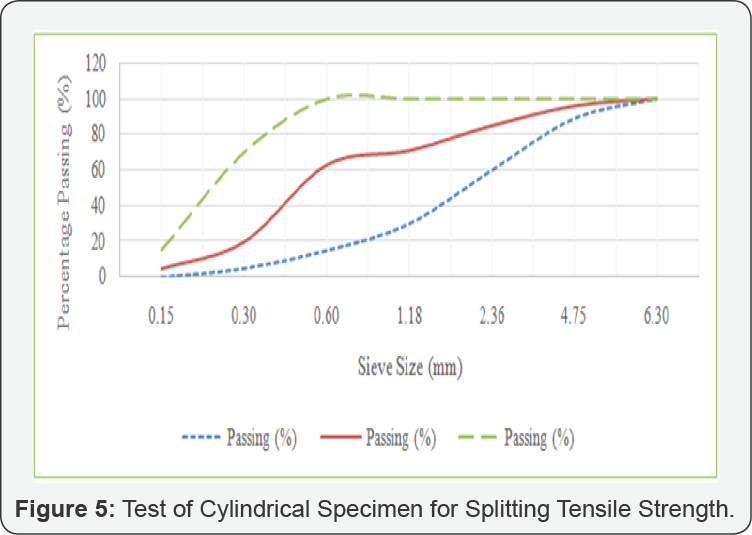

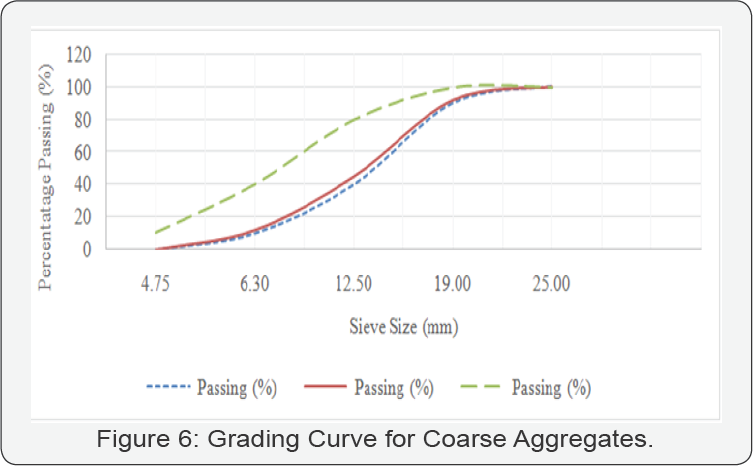

The particle size distribution conducted in

accordance with the BS882 were used to plot grading curve for the fine

and coarse aggregates shown in Figure 5 & 6 respectively. The grading curves and the physical properties given in Table 2 indicate the aggregates used for the study were within the accepted range for producing concrete.

Workability

Table 3

presents the result of workability test given the slump values for the

various mixing batches. It is noted that, slump values decreased as the

fines percentage in sand increased whereas the slump increased as the

water/cement ratio increased agreeing with earlier reports [16,20,21].

The decrease in slump value as a result of increase in fines percentage

in sand can be attributed to the fact that finer particles have larger

surface area which absorbs more water in concrete mix. Meanwhile, higher

water/cement ratio is able to disperse the concrete constituents

leading to a higher slump value. This result is again similar to the

reports by Alawode and Idowu and Olusola et al. [13]. The degree of workability is explained in the Table 3 where concrete batches with 0.70 water/cement ratio had better slumps ranging from minimum of low to maximum of medium slump.

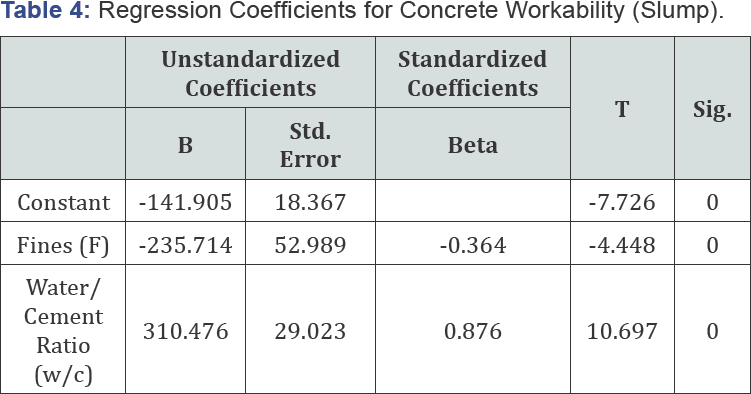

Regression analysis was conducted to predict the

relationship among the fines percentage in sand, water/ cement ratio and

workability of concrete presented in Table 4. The coefficient of multiple determination, R2 given as 0.899 (Adjusted R2=0.886)

indicates fines percentage in sand and water/cement ratio explains

about 90% of the variations in concrete workability. Moreover, the ANOVA

suggest the predicted equation is appropriate for determining the

effects of fines percentage in sand and water/cement ratio on concrete

workability (F = 67.111, p < 0.001). From Table 4,

an increase in fines content in sand by one percent resulted to a

decrease in concrete slump by approximately 236mm when all other

variables are kept constant. On the other hand, an increase in

water/cement ratio by one unit (0.01) resulted to an increase in slump

by approximately 310mm with all other variables kept constant. The Beta

values from the standardized coefficients suggest that, an increase of

the fines percentage in sand by a standard deviation will result to a

decrease in concrete slump on the average by 0.364mm. Meanwhile, an

increase in the water/ cement ratio by one standard deviation will

result to an increase in slump on the average by 0.876mm. Equation for

predicting concrete workability is hence given as:

Wc = -141.905 - 235.714F + 310.476w/c with R2 = 89.9%(Eqn. 1)

Goodness of fit: R2=89.9% (Adjusted R2= 88.6%); F = 67.111, p<0.001

Compressive and tensile splitting strength

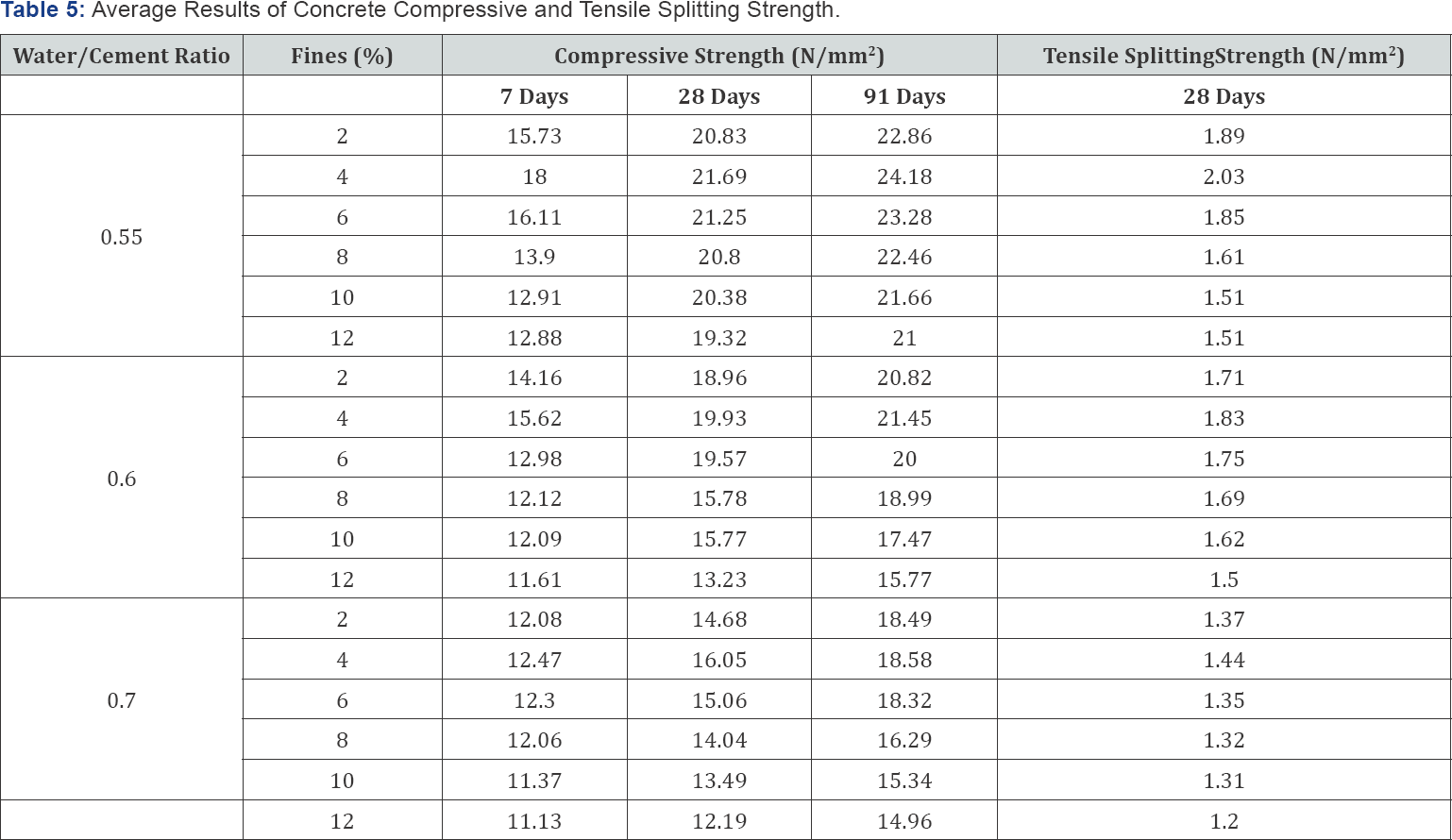

The compressive strength of concrete cubes tested at

7, 28 and 91 days curing as well as splitting tensile strength tested at

28 days curing are presented in Table 5.

It can be noted that, the strength of concrete (both compressive and

tensile splitting) increased to 4% fines content in sand beyond which

the strength decreased at constant water/cement ratio. The trend was

found to be consistent with the report by Seeni et al. ; Cho [16]; Dammo et al. [22]; Iyappan and Manu [21].

Meanwhile, at constant fines content in sand, the compressive and

tensile splitting strength of concrete decreased with an increase in

water/cement ratio at all curing ages. This trend again supported

previous investigation [13,14,23].

The reason may be that concrete with higher fines content in sand

absorb more water thereby living inadequate amount of water for the

hydration of cement leading to decreased strength. Moreover, higher

percentage of fines in sand will require higher amount of water to make

the concrete workable which intend result to lower strength of concrete.

Thus, higher water/cement ratio disperse the concrete constituents

resulting to less bridging of calcium-silicate-hydrate of cement

hydration rendering weaker strength of concrete.

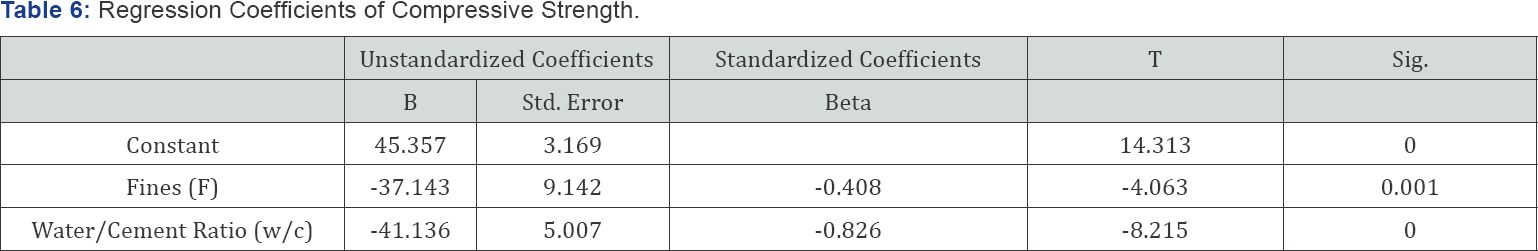

Computing regression analysis as shown in Table 6

for predicting compressive strength of concrete at 28 days curing, the

ANOVA indicates appropriate prediction using the model (F = 41.998, p

< 0.001) however is valid for concrete with 4% fines and beyond. The

coefficient of multiple determination, R2 = 0.848 (Adjusted R2

= 0.828) explains that fines percentage in sand and water/cement ratio

explains about 85% of the variations in the compressive strength of

concrete. The unstandardized coefficients indicates that an increase in

fines content in sand by one percent will result to a decrease in

compressive strength by 37.1N/mm2 when all other variables

are kept constant. On the other hand, an increase in water/cement ratio

by one unit (0.01) will cause a decrease in the 28-day compressive

strength of concrete by 41.1N/mm2 keeping all other variables constant. Table 6

again indicates that an increase in fines percentage in sand by one

standard deviation will cause a decrease in compressive strength of

concrete cube on the average by 0.408N/mm2. The water/cement

ratio when increased by one standard deviation will also decrease the

compressive strength of concrete on the average by 0.826N/mm2. The predicting equation is therefore given as:

fcu28 = 45.4357 - 37.143F - 41.136w/c with R2 = 84.8%

(Eqn. 2)

Goodness of fit: R2 = 84.8% (Adjusted R2 = 82.8%); F = 41.998, p < 0.001

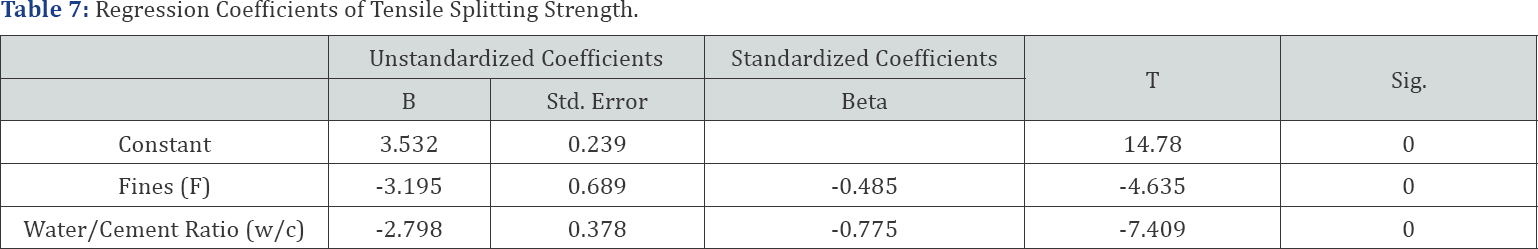

Table 7

also presents the regression analysis for the tensile splitting

strength of concrete. The coefficient of multiple determination, R2 indicates that, fines percentage in sand and water/cement ratio explains about 84% (Adjusted R2

= 0.814) of the variations in the tensile splitting strength of

concrete. More so, the test statistic from the ANOVA suggest adequate

prediction using the regression model developed (F=38.191, p<0.001)

also valid for concrete with 4% fines and beyond. The unstandardized

coefficients therefore indicate that, an increase of the fines content

in sand by one percent will cause a decrease of 3.195N/mm2 in

the tensile splitting strength of concrete when all other variables are

kept constant. On the other hand, by keeping all other variables

constant and increasing the water/ cement ratio by one unit (0.01) will

result to a decrease in tensile splitting strength by 2.798N/mm2.

Meanwhile, the standardized coefficients indicate that, an increase of

fines percentage in sand by one standard deviation will cause an average

decrease in tensile splitting strength of concrete by 0.485N/mm2.

An increase in water/cement ratio by one standard deviation also

decreased the tensile splitting strength of concrete on the average by

0.775N/mm2. This explains that water/cement ratio contributes

the highest effect on concrete tensile splitting strength. The model

predicting the tensile splitting strength is hence expressed as:

fct28 = 3.532 - 3.195F - 2.798w/c with R2 = 83.6% (Eqn. 3)

Goodness of fit: R2 = 83.6% (Adjusted R2 = 81.4%); F = 38.191, p<0.001

Conclusion

This study showed that, compressive strength of a

cube specimen made from the basic 1:2:4 mix proportion using cement

class of 32.5R is expected not to be less than 20N/mm2. On

this note, it was concluded from the study results that, sand fines and

water/cement ratio beyond 4% and 0.55 respectively significantly weakens

the strength of concrete. It is recommended that sand used in Ghana for

producing concrete should have fines limited to 4% maximum. Admixtures

are also recommended to be used to improve workability instead of

increasing water content with no recourse to cement addition during

concrete production. Moreover, the chemical and biological composition

of fines are recommended to be investigated to determine their influence

on concrete properties.

For More Open Access Journals Please Click on: Juniper Publishers

Fore More Articles Please Visit: Civil Engineering Research Journal

Fore More Articles Please Visit: Civil Engineering Research Journal

Comments

Post a Comment