Behavior of the Dry Bed Joint in the Mortarless Interlocking Masonry System: an Overview- Juniper Publishers

Juniper Publishers- journal of Civil Engineering

Abstract

Interlocking mortarless masonry has numerous benefits

over the conventional masonry due to its ease of construction and

higher compressive strength by virtue of absence of mortar joints. Dry

contacting surfaces between the blocks play a major role on the

performance of dry stack masonry. In this paper, Dry joint surface

characteristics and close-up deformation properties of interlocking dry

stack blocks and bricks were reviewed as well as the dry joint opening.

It was observed that the contact area increases with increasing of the

compressive load. It's concluded that the behavior of the interlocking

mortaless system is extremely affected by the behavior of the contact

surface and the dry joint under compressive loading. Therefore, further

research related to dry surfaces contact and interface closure and

opening characteristics under compressive loads is needed.

Keywords: Interlocking; Masonry; Dry joint; Mortarless; Contact behavior

Abbreviations: MBTSS: Matrix Based Tactile Surface Sensors; DIC: Digital Image Correlation; ISEB: Interlocking Stabilized Earth Block

Introduction

In the past few decades, the concept of interlocking

mortarless masonry unit has been widely increased in the field of civil

engineering applications and construction practices due to its field

productivity, efficiency and less skilled workers needed in the

production and implementation [1].

One simple thing that absolutely contrasts interlocking bricks from

conventional bricks is the mortar between bricks layers where mortar is

not required for the construction of interlocking bricks. Due to that

characteristic, the construction of masonry walls is faster and needs

even unskilled workers as the bricks are arranged dry and interlock each

other by the protrusions [2].

An assortment of interlocking bricks have been manufactured and

produced during the last few years, varying in the composition of

material, shape, size, strengths required, and usage needed, including

Sparlock, Meccano, Sparfil, Haener, and Hydraform block system [3].

Due to the absence of mortar and the filling material

between the masonry brick joints, the contact area need to be study

with particular attention. The understanding of the compressive behavior

of dry joints is a vital design parameter, for this reason only dry

joint compressibility should be examined. Moreover, dry contacting

surfaces between the blocks and bricks play a major role on the

performance of dry stack masonry [4].

Thus, dry interfaces characterize the behavior of dry stack masonry

under different loads. When the dry stack masonry is subjected to

compression the interfaces gradually close and the surface contact area

increases with the increment in loading [5,6].

However, very limited research outcomes are reported in the literature

on the characterization of the dry interfaces under key loading

conditions. In this paper, a review on the behavior of the contact area

between interlocking bricks or blocks layers is presented.

Dry Joint Closure

Previous studies tests have been conducted to

determine the behavior of contact area between brick layers and its

effects on the overall behavior of masonry systems.

Greve et al. [7]

have used matrix based tactile surface sensors (MBTSS) to determine the

contact pressure and contact area of the dry stack joint subjected

gradually to compression load normal to the dry interfaces. As MBTSS is

an expensive, a cheaper carbon paper insert technique was also utilized

to check its ability to trace surface contact area between the bricks

subjected to compressive loading incrementally. The imprints obtained

from the carbon paper were analyzed using Image J software that

determined the contact area. The comparison between the two techniques

revealed that the carbon paper imprints significantly and consistently

under-predicted the contact area. From the MBTSS data, it was concluded

that the contact pressure and contact area increased gradually under the

increase in loading. It was also observed that some high-pressure

points existed within the contact surface and the location of the point

remained unaffected throughout the loading history which demonstrated

that the unevenness of the surface did not even out even at loads very

close to the ultimate.

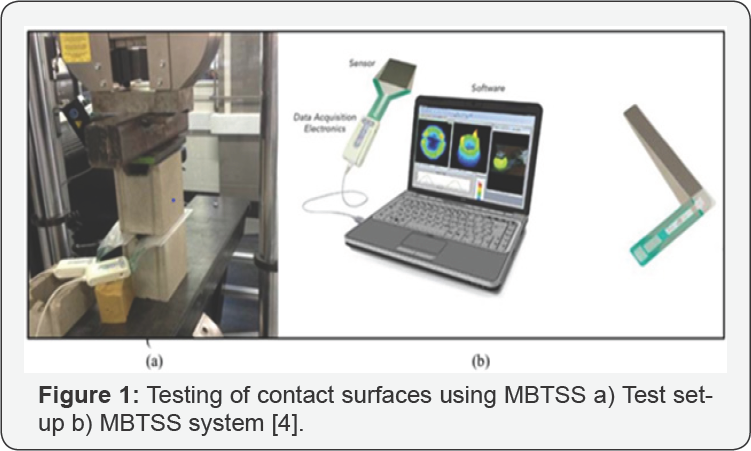

Zahra et al. [4]

have experimentally examined the characteristics of the dry contacting

surfaces of the concrete blocks and bricks. The contact surface area

between two blocks under progressive compression load is determined by

utilizing a matrix based tactile surface sensor positioned between the

contacting surfaces of the two adjacent blocks. The tactile sensor

determined both the contact area and the contact pressure distribution

between the block surfaces as shown in Figure 1.

The contact surface area was found to be progressively increasing from

about a minimum of 15% to a maximum of 95% of the net area with the

progressive increase in compressive load. In addition, the closing

deformation between the two surfaces under the compressive load was

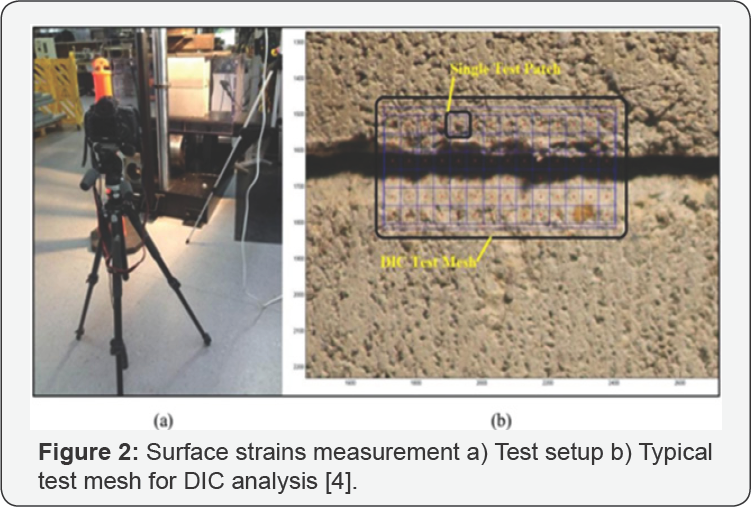

determined by a non-contact digital image correlation (DIC) technique as

shown in Figure 2.

Digital image correlation technique is extensively recognized for

measuring surface strains in numerous laboratory testing including

masonry [8,9].

The close-up joint deformations and strains were measured for

bi-stacked masonry prisms. The test images were analyzed by a special

program innovated by Willam

[9]

to evaluate the strains in the area of the dry joint. It is found that

the seating behavior of the dry interfaces in the early stage of

compression is obvious through the gradually stiffening curve.

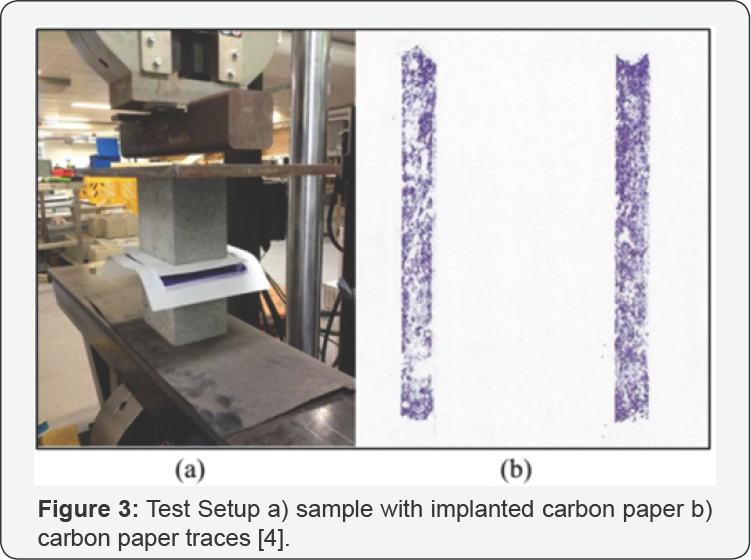

The carbon paper image imprints were traced for loading increments of 20kN from 0kN to100kN as shown in Figure 3.

Each imprint was then analyzed by Image J software to determine the

surface contact area. It can be observed that the contact area increases

with increasing in the applied load. The area is increased from a

minimum value to about 6500mm2 (82%) of the maximum contact area at

100kN for the half blocks,

Marzahn & Konig [6]

have examined the influence of the geometric imperfections in the bed

joints to the structural behavior of mortarless masonry subjected to

compressive loading. Results showed that the surface quality impacted

the strength of brick units where the more irregular the bed planes the

lower the strength because it causes initial deformation. However, the

load bearing capacity was lowered by only 5 to 15% compared to mortared

masonry due to the initial settlement.

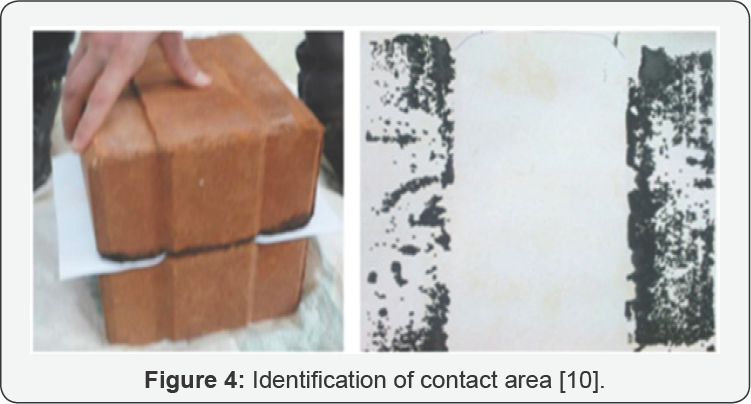

Ayed et al. [10]

have used an image analysis method to determine the behavior of the dry

stacked joint on the interlocking bricks. A plain white paper weighing

80g/m2 and free of physical or chemical effect on block has

been used. The interface of the interlocking blocks was painted and the

white paper between the blocks were placed in order to print the contact

area as shown in Figure 4.

An image analysis was developed on MATLAB in order to estimate the

percentage of the contact surface printed on the paper. It transformed

the image of the printed paper in white and black pixels. Counting of

pixels leads to the percentage of the contact area.

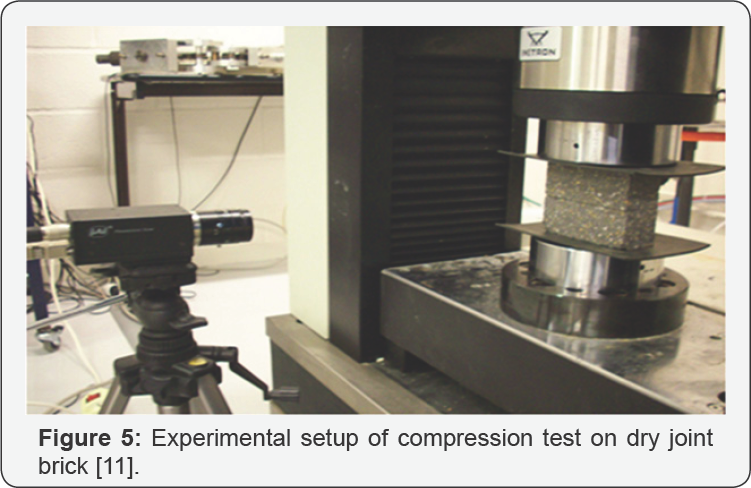

Another recent study conducted by Rekik et al. [11]

used Digital Image Correlation method to examine the compressibility of

dry joints. Compressive tests on specimens that cut from

Magnesia-Carbon mortarless bricks were carried out. Tests were conducted

using a load cell of 200kN as shown in Figure 5

with an accuracy of 0.2% of the attained load and 0.033mm/ min

displacement rate. 2D Digital Image Correlation is utilized to measure

the compressive behavior of the dry joint.

Similarly, Andreev et al. [5]

have investigated the dry joint closure behavior of refractory bricks

under compressive loading. Finally, the procedure of joint closure was

estimated in a roundabout way by stressing specimens with and without

joints in wide temperature extend.

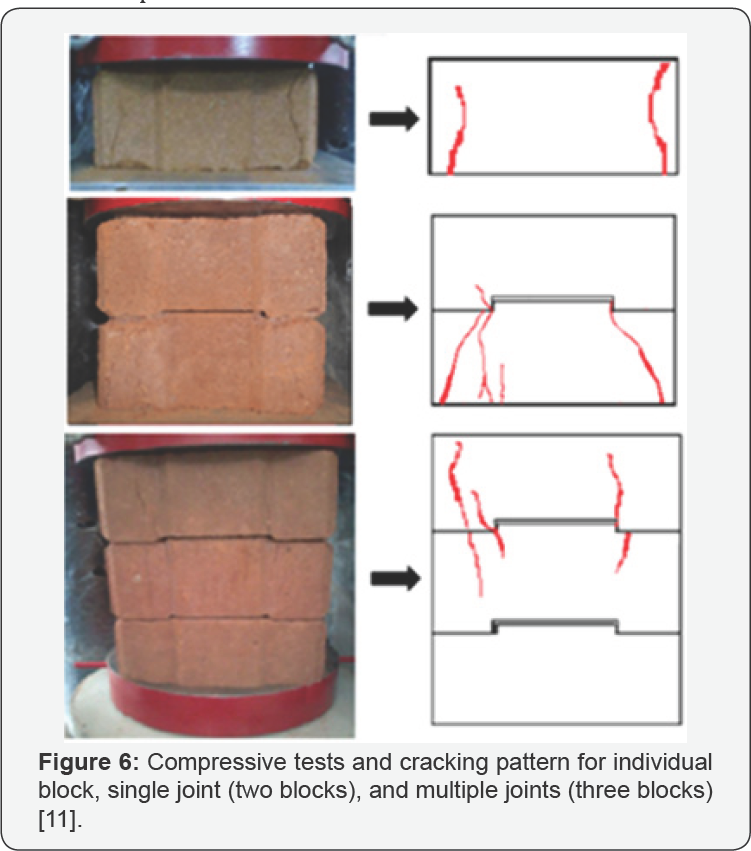

Ayed et al. [10]

have analyzed the effect of contact area and the clearance between the

blocks on the mechanical behavior of interlocking stabilized earth block

(ISEB). The ISEBs were placed dry without grouting and tested under

compression load tests to the mechanical behavior and the contact area

effects, while the effect of the local stress around the clearance were

performed by finite element modeling. The ISEB manufactured by red

earth, sand, and 8 percent of cement. The compressive tests were

conducted on individual block, single joint which consists of two

interlocking blocks, and multiple joints that consists of three

interlocking blocks as shown in Figure 6.

As a result, the compressive strength for individual block, two blocks,

and three blocks were 11.9MPa, 8.2MPa, and 5.5MPa, respectively. That

means the contact area and the clearance between the blocks have an

effect on the masonry compressive strength, causing it to decrease.

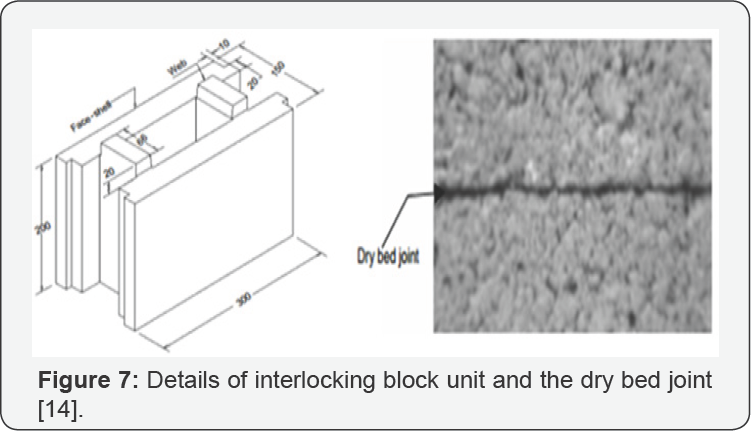

Jaafar et al. have investigated the behavior of the

dry joints of interlocking masonry under compressive loading and

consequently their impacts on the structural behavior of the

interlocking mortarless hollow blocks for grouted and ungrouted prisms

subjected to compression as shown in Figure 7.

Two test setups are experimentally proposed to determine the contact

behavior of dry joints with consideration of the geometric imperfections

in the contacting interfaces. Results revealed that the geometric

imperfections of the brick beds are highly affected the dry joint

behavior and hollow prism deformation. Varied deformation forms are

observed in mortarless un-grouted and grouted prisms. However, this

behavior isn't common in grouted prisms, for the reason that visible

deformation begins after 38% of the maxim loading. Besides, the

differences of strength and deformation in grouted samples are reduced

in compression with those in un-grouted samples.

Dry Joint Opening

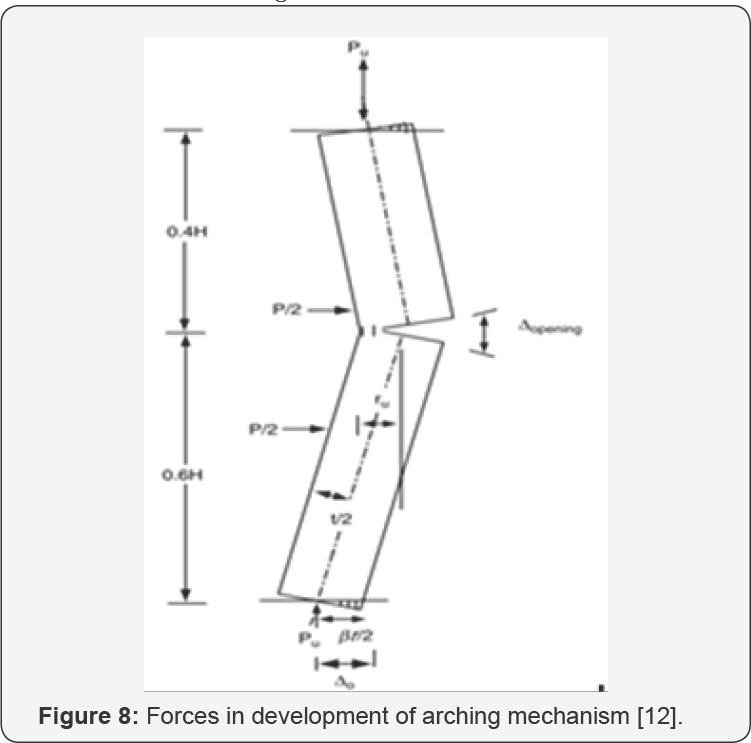

Studies stated that opening mechanism of wall

specimens may be explained by arching mechanism in out-of plane wall.

When a wall is subjected to load that is perpendicular direction to wall

face, the wall will deflect in the out-of-plane direction (same

direction where load applied). In mortarless construction, the wall

tends to create an opening between courses where the location of maximum

bending moment occurs. Opening mechanism in dry joint is related to the

arching behavior during out-of-plane loading. Resistance of hollow

masonry walls to out-of-plane loads can be increased by imposing large

in-plane compression forces that can be induced when the wall is rigidly

supported [12].

With increasing loading, flexural opening occurs at mid span. With the

increased load, the wall is hard-pressed against the un-yielded supports

producing clamping forces ( ) at the ends as shown in Figure 8.

Three hinged arches reshaped where the external moment is resisted by the internal couple (p u*ru) where ru is the arch height. The clamping force Pu is a function of dry joint and contact area. The arch height ( ru ) is a function of the wall geometry, contact area (βt/2) and deflection (Δo.β)

is a slope of the bottom course opening, where (t) is the wall

thickness. Therefore, the more the wall deflects, the lower the clamping

force Pu due to the reduction of contact area and thus decreasing of resulting moment.

Studies stated that opening mechanism of wall specimens may be explained bySafiee et al. [13]

have examined the dry joint opening of interlocking mortarless wall

subject to out-of-plane load. During testing, the dry joint opening

mechanism around mid-height of wall, as shown in Figure 9,

was dominated. The opening was measured by Demec points at several

locations along the wall surface. The opening of middle courses of wall

increased as lateral load increased for all series of specimens. The

total opening may be affected by both lateral load and higher

precompressive load. The study exhibited that the opening size was

higher even at lower load. However for the partially grouted walls, the

opening value was relatively limited and mostly occurred at higher

lateral load.

Discussion and Conclusion

Studies stated that opening mechanism of wall

specimens may be explained byDry joint surface characteristics and

close-up deformation properties of interlocking dry stack blocks and

bricks were reviewed in this study as well as the dry joint opening.

It's found that the carbon paper image analysis method is unsuitable to

determine the contact area between the block surfaces accurately.

Meanwhile, the tactile sensors system computes the surface contact area

consistently and reliably. It has been concluded that the contact

surface of the mortar less masonry bricks on initially remained

negligible due to the initial gap and voids between the blocks and

undulations on the dry joint surface. After certain amount of time the

contact area increased with a steep slope until it stabilized. Moreover,

through the image analysis of contact prints, it was shown that the

contacting areas increase with the increasing of the compressive load.

The behavior of the interlocking mortar less system is extremely

affected by the behavior of the contact surface and the dry joint under

compressive loading. The geometric imperfections of the bed interlocking

blocks and bricks were found to be a significant factors impacts the

structural behavior of the mortar less masonry system. Finally, for

increasing the acceptance of dry stack masonry system, further research

related to dry surfaces contact and interface closure and opening

characteristics under compressive loads is needed.

For More Open Access Journals Please Click on: Juniper Publishers

Fore More Articles Please Visit: Civil Engineering Research Journal

Fore More Articles Please Visit: Civil Engineering Research Journal

Comments

Post a Comment