System Analysis and Optimization of Multi-Contaminant Water Reuse Network with and without Regeneration using a Hybrid Genetic Algorithm- Juniper Publishers

Juniper Publishers- Journal of Civil Engineering

Abstract

This paper proposed methodology to analyse the

possibility of combination of hybrid optimization function with

Single-Objective genetic algorithm (SOGA) for solving the

multi-contaminant water reuse network with and without regeneration

design problem. A non-linear model was considered due to non-linear

multicontaminant constraints system. The freshwater use and wastewater

production has been minimized, by applying the proposed method.

Moreover, the parameters related to the implementation of the genetic

algorithm that increase computer speed and satisfy optimum result were

tuned before the result is confirmed. The solutions and parametric

values so obtained have been further compared with the existing

literature values. The results obtained are in agreement and comparable

to those obtained from other methodologies and it even shows better

result in considering multi-contaminant water reuse with regeneration.

Keywords: Optimization; Genetic algorithm; UNESCO; Heat-integrated water; Computational strategies

Abbreviations:

SOGA: Single-Objective Genetic Algorithm; WNS: Water Network

Synthesis; WNA: Water Network Analysis; WAP: Water Allocation Planning;

WAN: Water Allocation Networks; OTWA: Optimal Total Water Network; GA:

Genetic Algorithm; IWN: Industrial Water Networks

Introduction

Water is a key element for the normal functioning of

many industries. It is intensively utilised in food, pulp or paper,

pharmaceutical, petrochemical and chemical industries, and so on. The

industrial revolution inspired many industrial processes that utilize

water and dispose of it with a certain concentration of pollutant. The

waste water generated from industrial processes is usually treated in a

central common facility in order to remove contaminants and to meet

regulatory specifications for wastewater disposal.

However, as opposed to this conventional approach,

reusing and re-routing the water streams in an integral water network

helps in reducing the consumption of freshwater in the system, and

minimizes the amount of wastewater to be treated and disposed of in to

the environment. Reusing and re-routing the water streams can account

for significant financial investment in a plant (industry), as the cost

of the treatment units is dependent on the volume of wastewater that

requires treatment. Furthermore, in certain instances the level of

treatment required is quite substantial. Hence, it would be favourable

if the volume of water that requires treatment were reduced.

This leads to research in water-reuse, recycling, and

regeneration-reuse/recycle as a means of minimising freshwater use and

wastewater production. Regeneration involves partial treatment by using

water treatment and purification technologies such as membrane and steam

stripping prior to reuse or recycle. These different options for

minimising the volume of water used by the industries combined together

are termed water network synthesis (WNS) or water network analysis (WNA)

or water allocation planning (WAP).

Some of the works done in the area of water

minimization in continuous and batch processes are described by the

detailed reviews of [1], Foo, Khor et al. and Gouws et al. The previous

works that involve wastewater recycle, treatment and reuse within

(industrial) consuming processes dates back to 1970's. The critical need

in reducing both contaminants and consumption of water and energy

necessitate most of them, due to the fact that twenty percent of the

world's total water consumption (this widely exceeds fifty percent in

many industrialised countries) has been recently attributed to

industries by UNESCO.

The scientific community has been largely involved in

the topic of the design of optimal water networks in the last three

decades, through minimizing both economic and environmental objectives.

The design of Water Allocation Networks (WAN) is a complex task,

especially when multiple contaminants are treated in the same plant with

particular emphasis on the decision about the use of many regeneration

units. This problem has been identified in previous works (e.g.

Gunaratnam et al., Feng et al., Boix et al.) and formulated as a generic

framework considering one or several objctive functions. The analysis

of the dedicated literature shows that a robust approach that can take

into account large problems is far from being straightforward. Also, the

definition of constraints or assumptions must be specified and adapted

to a case study, thus hindering the development of a standard approach.

Although, the model-based optimisation approach allows handling of water

network synthesis problems in their full complexity by considering

representative cost functions, multiple contaminants and various

topological constraints, it frequently presents major challenges of high

computational burden to achieve optimality, and it does not guarantee

global optimum which provides the lowest value (known as global

minimum).

Some of the significant achievements in water network

analysis that utilizes optimization-based modelling techniques and

computational strategies are the work of Takama et al. [2] which provide

seminal work on water network synthesis using optimization approach.

Galan and Grossmann formulate optimization of distributed wastewater

treatment network using mixed integer nonlinear programming. Zamora and

Grossmann presented method for obtaining global optimization solution of

water network synthesis. Doyle and Smith proposed sequential

optimization approach in finding the optimal solution. Huang et al;

adopt a representation of fixed flow rate in the water network

synthesis. Savelski M and Bagajewicz M [1,3] provide rigorous proofs for

the necessary conditions of an optimal direct reuse/ recycle and

formulation of mixed integer linear programming for single contaminant

water network synthesis [1,3]. Koppol and Bagajewicz addressed the issue

of uncertainty in the water network synthesis problems.

Moreover, Faria and Bagajewicz proposed a planning

model and way of obtaining global optimum result with piecewise- affine

relaxation enhanced with bound contraction and also consider

pre-treatment for water network synthesis in their later work. Sujak et

al. [4] creates a model for the design of optimal total water network

(OTWN) [4]. Sharma and Rangaiah [5], proposed designing, retrofitting,

and revamping water networks in petroleum refineries using

multiobjective optimization [5]. Tan and Cruz apply stochastic

optimization based technique in water network synthesis problems.

Karuppiah and Grossmann proposed a piecewise-affine relaxation of non

convex terms in the solution of water network analysis. Tan et al.

consider membrane separation based water regenerators for total water

network synthesis. Hong et al. [6] proposed simultaneous optimization of

heat-integrated water allocation networks.

However, despite all the above mentioned significant

achievements in water network analysis research that utilizes

optimization-based modelling techniques and computational strategies

there are some challenges in the issues of non convexity (which leads to

the presence of multiple local optimal solutions), nonlinearity (which

is due to considering regeneration technologies as nonlinear mixed with

linear objective function), simultaneous optimization of the

interactions of rigorous design models for wastewater treatment

technologies and multiple water-using units, enabling faster numerical

solutions, development of more meaningful optimization-based

formulations, uncertainty (posed by the data obtained from the industry,

the assumed parameters in analysis of the problems), alternative

methods for optimization under uncertainty and extension to resource

recovery systems. However, all the above challenges and uncertainties

can be handled by using stochastic programming which is robust

optimisation method. The use of stochastic programming like Genetic

Algorithm (GA) can improve the potential future directions in water

network analysis and assist in developing feasible, cleaner and more

economic industrial water networks (IWN) that drastically reduced

freshwater consumption as well as wastewater, and ensure reasonable

costs and efficient productivity (Ramos et al.).

Inconsideration of the above, this paper developed a

general framework for water (fresh and waste) allocation planning (WAP)

that can be applied to different water allocation contexts e.g. oil

refinery, food production, pharmaceutical etc, by considering multiple

contaminants with and without regeneration. The WAP problem was solved

using a combination of stochastic genetic algorithm (GA) optimization

and hybrid function optimization method. The non-convexity and

nonlinearity challenges are adjusted by using reproduction parameters of

GA which includes Elite Count and Crossover fraction to obtain possible

solutions by the use of Population creation function

that is constraint dependent. The optimization method handles

interactions of rigorous design models for wastewater treatment

technologies and multiple water using units simultaneously. The

solutions and parametric values so obtained from a case study of three

processes have been further compared with the existing literature

values.

Methodology

Superstructure for integrated water network (IWN) allocation problem

The superstructure model for IWN allocation problem

as proposed by Ramos et al. is shown in Figure 1. It is generalization

of the model given by karuppiah and Grossman and Ahmetovic and Grossmann

[7]. The first part consists of freshwater source, water from

regeneration units and from other process units all linked in to a

mixer. This is followed by connection to different processes for further

operation and addition of more contaminants strictly based on the

acceptance level of contaminant concentrations of each process. The

output water flow is linked to the splitter that separate flow in to

discharge as wastewater, flow to regeneration units and to other

processes. The second part starts with the mixer of water from process

units and from other regeneration units link to further regeneration and

passed to splitter which link the water flow to other process units and

further regeneration units (Figure 1).

Formulising the water minimisation problem with and without regeneration

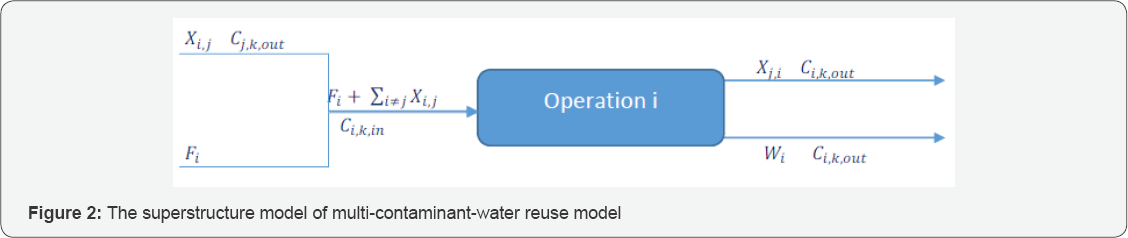

Multi-contaminant-water reuse without regeneration model

Fitness function: The fitness function for

multi- contaminant-water reuse without regeneration model which is the

sum of fresh water flow rates at the entrance of all water using

processes is presented in equation1 (Figure 2).

Where, F is the flow rate of freshwater entering operation in tons/h.

Constraints

Linear Constraints functions: The linear

constraint function of the water mass balance of all processes involved

in Multi contaminant water reuse is presented in equation 2.

Where, Xi ? is the flow rate of water reuse form to in tons/h, and

W is the wastewater flow rate out of the process in tons/h.

Nonlinear constraints functions

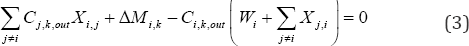

i. The nonlinear constraint function of the

contaminant mass balance of all processes involved in multi-contaminant-

water reuse is presented in equation 3:

Where, c,,k is the average inlet concentration of contaminant to process in ppm.

ΔMjk is the average mass load of each contaminant for each operation in g/h.

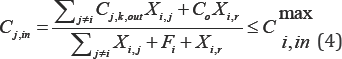

i. The nonlinear constraint function of maximum contaminant inlet concentration involved in

multi-contaminant-water reuse is presented in equation 4:

Where, Cj,k,in is the average inlet concentration of contaminant k to process in ppm.

Cj,k,out , is the average outlet concentration of contaminant k to process in ppm.

Multi-contaminant water reuse with regeneration model

Fitness function: The fitness function for

multi-contaminant water reuse with regeneration model which is the sum

of fresh water flow rates at the entrance of all water using processes

is as presented in equation 1: (Figure 3).

Constraints

Linear Constraint functions: The linear

constraint function of the water mass balance of all process involved in

multi-contaminant- water reuse with regeneration is presented in

equation 5.

i. The nonlinear constraint function of the

contaminant mass balance of all processes involved in

multi-contaminant-water reuse with regeneration is presented in equation

6.

Where, Cok , is the average regeneration outlet concentration of contaminant in ppm.

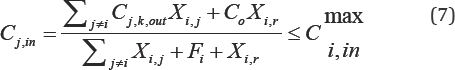

ii. The nonlinear constraint function of the Maximum Contaminant inlet concentration involved in

multi-contaminant-water reuse with regeneration is presented in equation 7:

Where, all the symbols are as described in the first model description.

The main difference between multi-contaminant-water

reuse with and without regeneration model is that the later has

reconnection of water reuse after regeneration which includes the

processes and streams connected to the regeneration unit, and the former

has no regeneration that links to the processes and streams after use.

Solving the water minimisation problem using a GA Algorithm

For solving the equations above (1-7) the SOGA was

used and in order to further improve the diversity and convergence of

the solutions obtained by SOGA, a hybrid function was incorporated. The

hybrid function "fmincon" is adopted to prevent the GA from getting

stuck in the local minimum solution of the WAP. "Fmincon" uses a Hessian

as an optional input.

Initial generation of chromosomes: The initial chromosomes were randomly generated by the Matlab software using boundary limits of all positive real values i.e Xu} >

0 . The binary values (1 and 0) of all the variables in each equation

were identified. A value of 1 is assigned to the position of the

variable if it exists in the equation and 0 otherwise. The values of

contaminants were directly used in the equations as either the

coefficient of the variable or as a constant.

Genetic algorithm in matlab:The SOGA is the basis used for solving the proposed optimization

model in Matlab, and in order to further improve the

diversity and convergence of Pareto optimal solutions obtained by SOGA, a

hybrid function is incorporated. The hybrid function works after the

exhaustion of the combined crossover and mutation operator that improved

the search ability of the algorithm.

Method for the hybrid approach: Incorporating a

search method within a genetic algorithm can improve the search

performance on the condition that their roles cooperate to achieve the

optimization goal [8] (Tarek et al). The hybrid function "fmincon" is

adopted to prevent the GA from getting stuck in the local minimum

solution of the WAP. "Fmincon" uses a Hessian as an optional input. This

Hessian is the matrix of second derivatives of the Lagrangian equation.

The Hessian is the matrix of second derivatives of the objective

function.

In single objective GA the hybrid function starts at

the best point returned by the GA. The method involves combining

principles of Genetic Algorithms (GA) and SQP algorithm that performs

the computation of the Hessian of the objective function and its

non-linear constraints. The hybrid function prevents the GA from being

stuck in the local minimum solution of the WAP problem.

The Hessian for a constrained problem is the Hessian

of the Lagrangian of an objective function f, nonlinear inequality

constraint vector c, and nonlinear equality constraint vector ceq, the

Lagrangian is given by equation 8.

The are Lagrange multipliers.

The Hessian of the Lagrangian is shown in equation 9.

Matlab software provide SQP as "fmincon" which

minimise constraint function based on a powerful concept in optimization

known as trust regions. "Fmincon" uses a Hessian as an input function.

Key steps in waste water minimization for multiple contaminant problems

A number of key steps are to be followed for implementing a Wastewater minimization project [9].

Step 1: The need of waste water minimization identified based on limited availability of freshwater,

economic and environmental regulation consideration.

Step 2: Data related to plant/industry is collected

which include fresh water use by a particular unit, process quality

requirement, cost and capability of treating water for initial input to

the process and the wastewater generated in the end by the process.

Step 3: Drawing a flow sheet of the processes, which shows water balance diagram of the processes.

Step 4: Identification of the key contaminants for

the processes; these are the contaminants that are to be reduced so that

the discharged waste water can be reused or disposed under the

specified control standards for an industry.

Step 5: The approach applied for solving the

wastewater minimization problems. Mathematical programming approach: It

involves definition of superstructure by considering each process within

an industry to have a certain freshwater flow rate, output water from

other process and or regenerated water, the output from the process will

have effluent with certain level of pollutants concentration which can

be discharged, recycled or regenerated for reuse, mathematical

optimization and analysis of solution.

Step 6: After carrying out various analysis and calculations a Wastewater minimization project can be

implemented.

Algorithm implementation

The basic flow chart for the implementation of

Genetic Algorithm (GA) is shown in Figure 1. However, depending on the

optimization software used in finding the solution, the steps may

require a little adjustment in execution.

This paper uses Matlab software for implementing the

steps; as such the following adjustments were adopted in obtaining the

best result.

Steps in genetic algorithm implementation in Matlab:

a. Combining all variables in one vector.

b. Writing vector for lower and upper bounds ( lb and ub ).

c. Writing matrix and vector of inequalities ( A and b)

d. Writing matrix and vector of equalities ( Aeq and beq ).

e. Writing nonlinear constraint function.

f. Calling the solver: [x fval] = ga(fitnessfcn, nvars, A,b, Aeq, beq, lb, ub)

Algorithm testing

As the parameter setting that is good for one problem

may not be suitable for another one sensitivity analysis of the

parameters of the GA approach was done to identify the parameters that

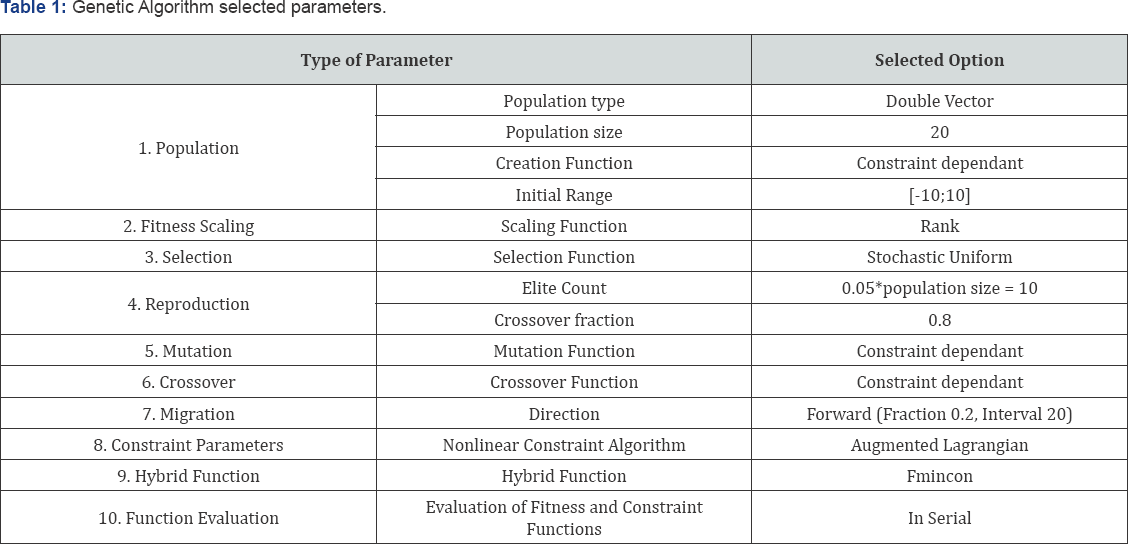

produce quality solutions [10,11]. In this research all parameters

related to the implementation of the genetic algorithm were tuned before

the algorithm is confirmed. These parameters are Population, Fitness

Scaling, Selection, Reproduction, Mutation, Crossover, Migration,

Constraint Parameters, Hybrid Function and Function Evaluation (Table

1). These parameters were chosen so that the optimal, or at least a good

one, solution is found. Obviously, by the stochastic nature of Genetic

Algorithm (GA), multiple runs on the same problem are necessary to get a

good estimate of performance.

Furthermore, in order to verify the adopted methodology the solutions obtained have been further

compared with the existing literature obtained values.

Case Studies

The genetic algorithm program was used in two

important examples in chemical engineering industries. The examined

industrial cases have significant usage and discharge of fresh water and

wastewater. The first case has three industrial processes and three

contaminants but without regeneration. The second case is as the first

case but with addition of regeneration.

Multi-contaminant water reuse without regeneration for 3 (Three) industrial processes

Considering an integrated optimization approach in

multiple contaminant system that contains n operations, m contaminants,

the numbers of variables involved are and there are equality constraints

[12].

The Linear Constraint is derived from the water mass

balance and the nonlinear constraint is derived from the contaminant

mass balance and the maximum contaminant inlet concentration. The lower

bound was set to zero to control all variable as positive numbers,

while, the upper bounds was set to infinity.

Case Study: Input limiting process data The example

data used have three process units and three contaminants, is fMann and

Liu [13], with the limiting water data for the industrial process units

shown in Table 2

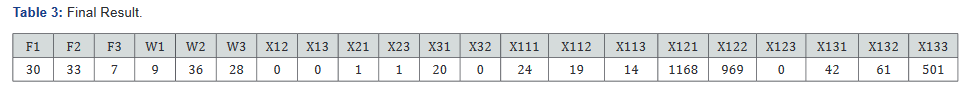

Final points: Optimization terminated because

the average change in the fitness value is less than function tolerance

and constraint violation is less than constraint tolerance. The solution

process further proceeds by switching to the hybrid optimization

algorithm (FMINCON) and satisfy the constraints. "Fmincon" stopped

because the size of the step is less than the default value of the step

size tolerance and constraints are satisfied to within the default value

of the constraint tolerance. FMINCON come to termination because the

objective function is non-decreasing in feasible directions, to within

the default value of the function tolerance, and constraints are

satisfied to within the default value of the constraint tolerance. The

final result is shown in Table 3.

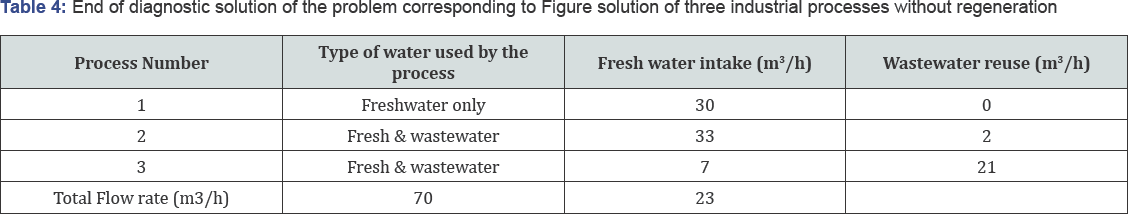

The Superstructure representation of results for

three (3) processes is shown in Figure 4. This shows the optimum water-

using network for an example problem of multi-contaminant without

regeneration-water reuse.

Solution of the problem corresponding to the

diagrammatical Superstructure representation of the solution is shown in

Table 4. It described the obtained result, indicating that the minimum

total freshwater required by the industry is 70.0m3/h, 30m3/h for process 1 and 33.0m3/h for process 2 and 7.0m3/h for process 3. While, process 2 and 3 reuse 2.0m3/h and 21.0m3/h of wastewater respectively, from process 1.

Solution of the problem corresponding to the

diagrammatical Superstructure representation of the solution is shown in

Table 4. It described the obtained result, indicating that the minimum

total freshwater required by the industry is 70.0m3/h, 30m3/h for process 1 and 33.0m3/h for process 2 and 7.0m3/h for process 3. While, process 2 and 3 reuse 2.0m3/h and 21.0m3/h of wastewater respectively, from process 1.

Multi-contaminant water reuse with regeneration recycle for 3(Three) industrial processes

Considering an integrated optimization approach in

multiple contaminant system that contains n operations, m contaminants

and regeneration units, there are 2n variables more than water reuse

without regeneration. The numbers of variables involved are + 3n + nm and there are n + nm equality constraints [12].

The fitness function which is the sum of fresh water

flow rates at the entrance of each water using process is as presented

in equation 1.

Test problem: Input limiting process data: The

example data used have three process units and three contaminants, and

is taken from Mann and Liu (1999) and [13], with the limiting water data

for the process units shown in Table 2 is used with the limiting water

data for the process units shown in Table 2 is used with an assumed

regeneration contaminant concentration of 25ppm:

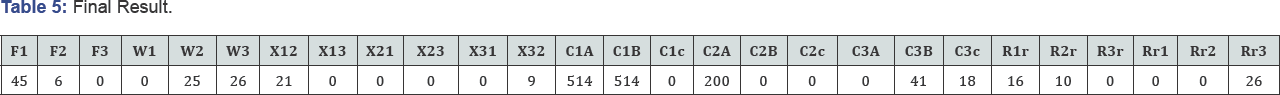

Final points: Optimization terminated because

the average change in the fitness value is less than function tolerance

and constraint violation is less than constraint tolerance. The solution

process further proceeds by switching to the hybrid optimization

algorithm (FMINCON) and satisfy the constraints. "Fmincon" stopped

because the size of the step is less than the default value of the step

size tolerance and constraints are satisfied to within the default value

of the constraint tolerance. FMINCON terminated. because the objective

function is nondecreasing in feasible directions, to within the default

value of the function tolerance, and constraints are satisfied to within

the default value of the constraint tolerance and the final result is

shown in Table 5.

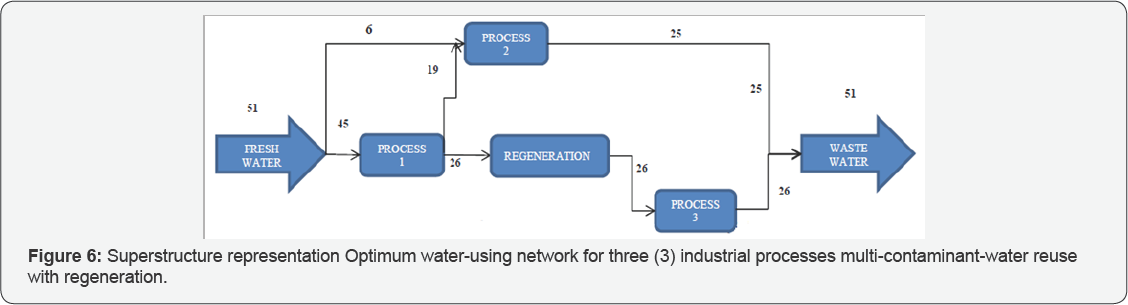

The Superstructure representation of result for three

(3) the optimum water-using network for an example problem of processes

with regeneration is shown in Figure 5. This shows multi-contaminant

with regeneration-water reuse (Figure 6).

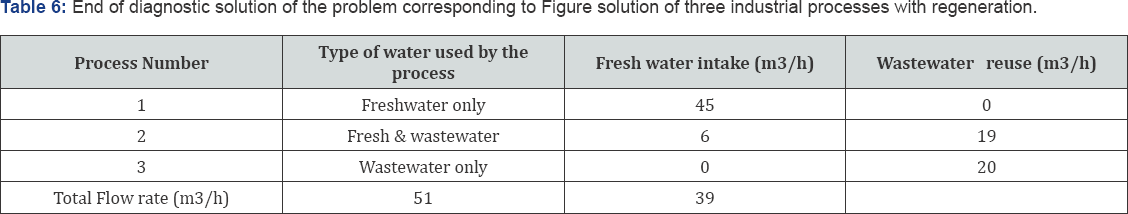

Solution of the problem corresponding to the

diagrammatical Superstructure representation of the solution is shown in

Table 6. It described the obtained result, indicating that the minimum

total freshwater required by the industry with regeneration of 25ppm is

51.0m3/h, 45m3/h for process 1 and 6.0m3/h for process 2. Process 2 use additional 19.0m3/h of wastewater. While, process 3 reuse 20.0m3/h of wastewater only, from process 1 after regeneration.

Comparison of the obtained result with the existing literature value

Table 7 shows that the result obtained from the

solution of multi-contaminant water reuse without regeneration for

minimum freshwater consumption or wastewater generated is equal to that

obtained from the literature. Moreover this study consider regeneration

in the second case i.e multi-contaminant water reuse with regeneration

with an assumption of 25ppm contaminant regeneration quality, while the

literatures mentioned [13] (i.e Mann and Liu) did not find solution to

that case.

Conclusion

The genetic algorithm has major advantages of

flexibility and robustness as a global optimum result search method.

Although, it uses stochastic optimization it can deal with highly

nonlinear problems and on differentiable functions as well as functions

with multiple local optima and is readily amenable to implementation,

which renders them usable in real-time problems of WAP. The nonlinear

programming solutions for multi-contaminant water network with and

without regeneration are presented. The approach was based primarily on

using MATLAB in implementing the genetic operators. A standard

formulation was proposed that can be modified to suite a wide variety of

WAP problems. The only data required are the number of processes, their

associated maximum inlet and outlet concentrations, the mass load

generated for each contaminant and the number of regeneration units with

the corresponding efficiency related to each contaminant [14-23].

The best genetic algorithm parameters for obtaining a

good result were presented, followed by the implementation. Finally the

obtained results were compared with the literature values.

The model shows better result in considering multi-contaminant water reuse with regeneration.

Moreover, the future study will consider

multi-objective optimization of water reuse network using multiobjective

genetic algorithm capabilities of Matlab.

Acknowledgment

I would like to knowledge Petroleum Technology Development Fund (PTDF) Nigeria for funding this research.

For More Open Access Journals Please Click on: Juniper Publishers

Fore More Articles Please Visit: Civil Engineering Research Journal

Fore More Articles Please Visit: Civil Engineering Research Journal

Comments

Post a Comment