Forward Osmosis: Commercialization and Acceptance Considerations- Juniper Publishers

Juniper Publishers- Journal of Civil Engineering

Keywords

Keywords: Forward osmosis; Desalination; Thermodynamic

Abbreviations:

FO: Forward Osmosis; O&G: Oil & Gas; WDR: Water Desalination

Report; MBR: Membrane Bioreactor; HTI: Hydration Technology Innovations

Introduction

Until recently, forward osmosis (FO) has been

primarily an academic pursuit. Significant scientific work and

development have further advanced the technology, opened new

applications, and improved both the financial and technical merits of

the process. However, limited publicly available information on real

world applications, cost data, and experience with engineered

applications of FO has limited market acceptance and penetration. FO is

now growing rapidly due to recent technical innovations, better suited

applications, increased demand for novel solutions for difficult waters,

and increased exposure.

This work seeks to give an expert's perspective on

the progress made, and remaining work to drive the FO process toward

greater acceptance. Throughout this investigation it is assumed the

reader has a general understanding of osmotic processes. For simplicity,

all osmotically driven membrane processes are referred to simply as FO.

FO in the Minds of the Public

FO has long had a fragmented reputation, with

advocates on one side and opponents on the other. Relatively little the

general public and even water industry insiders know about FO feeds this

cycle. As such, each new article on FO claims the process as either a

"break-through" or just another example of "too-good- to-be-true". Those

working in FO know the reality is somewhere in the middle. An excellent

example is the years of FO being marketed as an energy efficient

alternative to RO desalination, and the inevitable blowback from

sceptics who point to the thermodynamic minimums for desalination.

One bright spot in this information duality are

industry specific articles. Water Desalination Report in April of 2013

ran two weekly issues completely devoted to various FO processes, the

state of the technology and market, and identified the various players.

In addition, FO news is often presented and very well covered in WDR

(Water Desalination Report, Vol 49 Nos. 14-15, April, 2013). Increased

coverage from a variety of sources will serve to educate potential

clients on the benefits of FO.

FO markets

One benefit of FO is a relatively large and varied

market potential. The main markets FO can and is having an impact in

include Oil & Gas (O & G), Industrial, Food and Beverage, and

Municipal. Across all markets, FO competes best where either difficult

waters are being treated or there is an existing waste energy source

that can be harnessed by various FO processes (chemical or thermal

gradients).

In the O&G and industrial markets, uses for the

FO processes fall into either waste minimization or resource

recovery/product concentration (or both). A thermal FO process is used

by Oasys Water in Texas to treat produced water in a waste minimization

scheme. The process is able to utilize waste heat to reduce the volume

of produced water by 60%, minimizing the waste stream. Additionally, the

resultant streams from the process illustrate how, when separated,

waste can become a resource; the 700ppm freshwater stream and the

240,000ppm brine stream can both be reused for other purposes (Oasys

Water, 2018). Another industrial market example is the use of FO+RO by

Porifera for treatment of manufacturing wastewater for high purity reuse

and near ZLD. While conventional membrane technologies fouled rapidly

on the wastewater (COD, oil, grease, surfactants), the FO+RO system was

able to recover 80% of the water and achieve high purity targets, which

in this case could not have been met with a thermal process [1].

The food and beverage market likewise has several

different areas where FO can be brought to bear including food product

concentration, direct-to-consumer products, and process wastewater

treatment. Food products could potentially be concentrated with FO

utilizing food based draw solutions. Such an application would allow the

concentration of food without applying heat and/or pressure. Hydration

Technology Innovations (HTI) also markets direct-to-consumer hydration

products utilizing FO membrane bags and a nutrient draw solution. These

products are marketed in the outdoor and emergency response sectors [2]. Process wastewater treatment applications are similar to the municipal market discussed below.

As of yet, there is very little penetration of FO

into the municipal market. However, potential applications include water

treatment, wastewater treatment, and perhaps most likely, water reuse.

While FO could certainly be applied to water treatment applications it

would be difficult to compete cost effectively with conventional

treatment technologies unless the water is difficult for conventional

technologies to treat. This in large part includes desalination,

although difficult to treat waters or areas with an abundance of low

grade waste energy could compete. Modern Water has completed and

operated for the last several years the only two commercial FO

desalination plants in the world (Gibraltar and Oman), and acknowledges

that FO is best able to compete with conventional desalination on

"challenging" waters (Modern Water, 2018). On the wastewater front, FO

has been tested in a Membrane Bioreactor format (Osmotic MBR, OsMBR) [2].

These systems would prove beneficial in a system where very high

quality permeate is required (OsMBR permeate to RO membranes) or where

the diluted brine can be used as is (such as dilution of RO brine before

discharge). The main benefits of the OsMBR are the high rejection of

dissolved solids at the FO membrane and the potential to use an existing

waste energy for the MBR separation [3].

The characteristics of FO include the ability to

treat very difficult feed waters, and provide exceptionally clean

permeate. These two characteristics position FO very well for water

reuse schemes in which a very impaired source must be purified to a very

high level. These schemes essentially bring the water and wastewater

treatment abilities of FO together; for instance using an OsMBR to

dilute seawater before desalination or a thermal FO process to purify

produced water for reuse (Table 1).

Market players

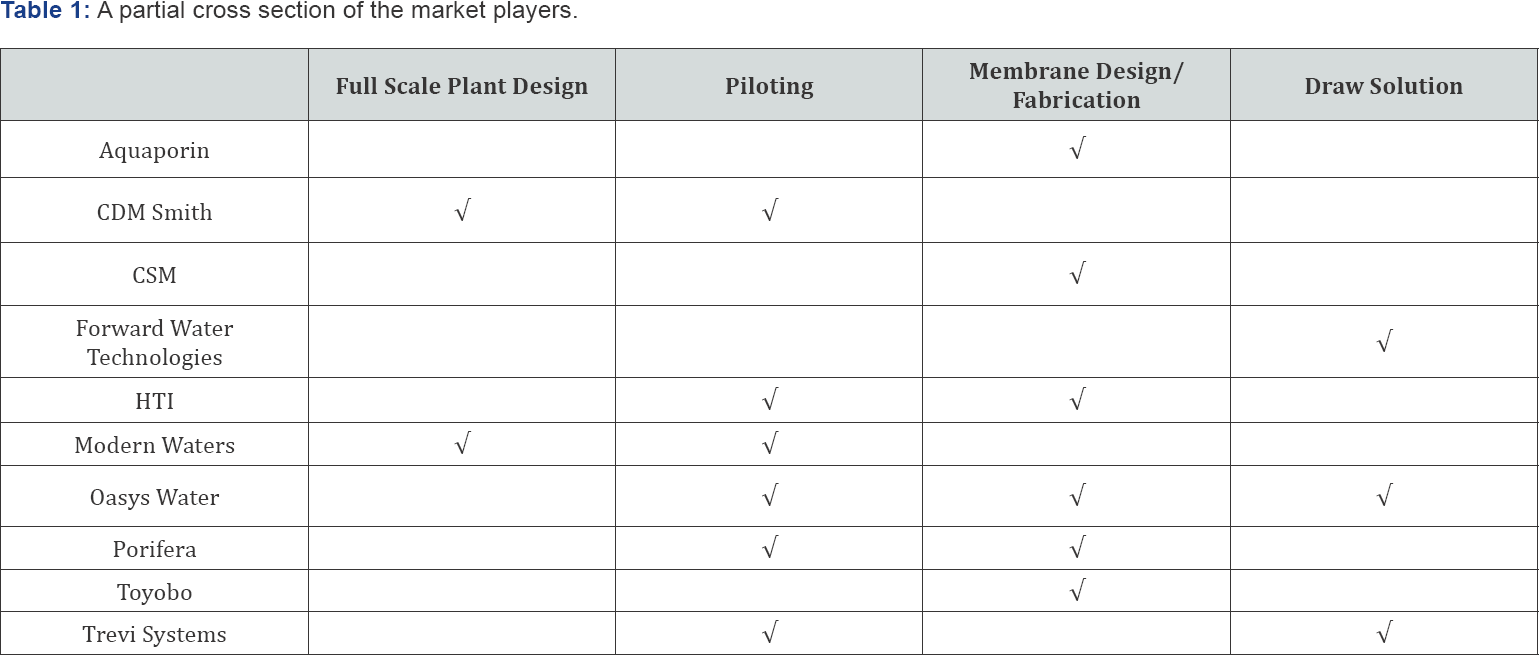

Players in the FO market have proliferated in recent

years as water sources have become less conventional, processes and

membranes have improved, and potential customers have become more

comfortable with FO. A partial cross section of the market players is

included below.

Barriers to Wider Use

While significant efforts have been made in the last

few years to allow the wider use of FO, several barriers still exist.

Some of these must simply be pushed through with effort and persistence.

However, several of the remaining barriers can be removed through

coordination of the various market players.

The largest and most difficult barrier for any new

water technology is the closed, slow moving water markets run by

conservative owners and engineers. Particularly in the municipal market,

both owners and engineers are hesitant to use any new technology that

has anything less than a long track record going back decades. The

industrial market is somewhat less conservative and more willing to take

a risk on a somewhat proven technology that promises to save time,

money, or effort in their processes. As such, the first steps of

breaking into the water market have always been piloting, industrial

use, and eventual adoption by the municipal market. The FO industry is

now operating a significant number of pilot systems and beginning to

break into the industrial market. A recent example of this is the

announcement that Oasys Water won a bid industrial treatment project in

China [4]. Publication and promotion of these successes will help to establish a reputation for FO.

Use of non-NSF-60/61 materials and chemicals is

another barrier for wider use, at least in the potable (and thus

generally municipal) water market. In many regions (including many

states in the USA) the use of non-NSF certified materials and chemicals

is prohibited for potable water systems. If non-NSF systems are to be

used in these cases either the materials and chemicals must be certified

by NSF for potable water use, or the process must be redesigned to

eliminate the non-certified materials and chemicals. Similarly, some

regions require regulatory approval for all new potable water treatment

technologies. In these cases, extensive piloting is typically required

before approval.

The proprietary nature of many of the FO systems and

materials are also a barrier to use, although the MF/UF market shows

that this can be overcome. It is clear that vendors and manufacturers

prefer a proprietary approach for its higher margins and more flexible

mechanical design, however this type of market makes designing,

specifying, and bidding systems and technologies more difficult and many

(mostly municipal) owners resist proprietary formats. Lastly, there is a

lack of clear and consistent cost data for FO systems. Consultants and

owners have a general knowledge of the cost of various conventional

technologies that can be employed, but have no way of developing high

level estimates for an FO system alternative. This lack of information

could be combated with consistent and real world case studies

highlighting the CAPEX, OPEX, and process parameters of completed pilots

and full scale plants, but what is really needed is several

competitively bid projects across the FO market [5].

Drivers for Wider Use

Although barriers exist, there are also significant

drivers for wider use of FO across the industries discussed. These

drivers generally fall into one of two categories; sole solutions to

emerging problems, or efficient solutions to existing problems. For an

FO system to fit an application, it must meet one of these two drivers.

Situations in which FO is the sole solution to an emerging problem are

relatively rare. Examples of these types of applications may include

food concentration in the food and beverage industry. While there are

other ways to concentrate food, it could be conceived that there are

foods for which application of heat or pressure is not acceptable.

Another sole solution situation is water recovery from extremely fouling

or highly concentrated waters, where significant strides are being made

by the various FO market players.

Many FO applications will be an efficient solution to

an existing problem. An example of this is the use of waste heat for

the thermal FO treatment of produced water. While conventional

technology could solve the problem, FO is able to do so in a more

efficient manner. It should be noted that in most of these situations,

the improved efficiency comes not from consuming less energy, but from

consuming energy from a waste source. An example of an application where

FO truly does consume less energy could be FO dilution of seawater with

wastewater before desalination. In this case, the use of FO is more

efficient than separate wastewater treatment and desalination steps

How to get municipal acceptance

Municipal acceptance of new technology is much more

difficult than industrial or food and beverage. Municipal owners and

engineers tend to be much more conservative and want to be ensured of a

long lasting, reliable, and robust system. Typically municipal owners

prefer to be able to manage the system as needed, which necessitates

simple and reliable operation. Another difference from the industrial

market is that technologies are typically recommended by the consultant

to the owner; thus, initial education and marketing should be focused on

consultants. However, owners will still require significant education

before they will be willing to accept a technology they are unfamiliar

with. Most municipal projects are bid, and specifications require at

least two (usually three) acceptable vendors. Therefore, after

successfully getting specified the vendor still must out bid one or two

other vendors. In rare occasions an owner and consultant may decide that

a sole source specification (where only one vendor is listed) is

acceptable. In this case, the vendor is not required to compete.

Generally in the case of a sole source, an agreement between the owner

and vendor is established before the project is bid [6].

Stakeholders prospective

The goals of owners, consultants, and suppliers are

in some cases similar and in some cases different. From the perspective

of the owner, they would like a low cost, reliable system, preferably

with several acceptable vendors for both initial purchase and ongoing

maintenance and upgrades. The FO suppliers, on the other hand, would

prefer proprietary solutions as these are less risky at bid and lock the

owner into the vendor's replacement and upgrade services. Consultants

tend to fall in the middle. Proprietary systems are acceptable, but they

still strive for a lowest lifecycle cost solution. Regardless, all can

agree that FO should be used in every correct and most efficient

application (Figure 1).

Going forward

From a consultant's perspective, there are several

short term items that would help sell the process both to other

consultants and prospective clients.

Consistent defendable success stories: For

each application, a success story showing the benefits, costs, and

expected outcomes from use of the FO process. Preferably these would be

published or presented at conferences.

Process design information: Publically

available membrane or process cut sheets and/or projection software

allowing the engineer to develop conceptual process values, energy

demand, and sizing for an application.

Reliable cost information: Cost information as

a function of membrane area, flow rate, or other independent parameter

to allow budget level lifecycle cost estimation. This should include

consumables and estimated membrane replacement.

Proprietary package information: Literature

presenting typical integration the FO system into the overall treatment

process including required supplementary equipment.

For More Open Access Journals Please Click on: Juniper Publishers

Fore More Articles Please Visit: Civil Engineering Research Journal

Fore More Articles Please Visit: Civil Engineering Research Journal

Comments

Post a Comment