Visual Interpretation of DEM Fill Mechanisms for a Rope Shovel Dipper in Dry Broken Rock- Juniper Publishers

Juniper Publishers- Journal of Civil Engineering

Abstract

A discrete element model (DEM) particle flow code

(PFC) based 2D numerical simulation was used to model the behaviour of

crushed cohesion-less rock fragments passing into a rope shovel dipper

(bucket); mimicking previous field verified physical 1/32nd

scale tests. While the previous physical tests showed the development of

a previously unknown void space within the dipper that perpetuated low

dipper fill factors; the model reported in this paper was developed to

show the impact of particle size characteristics on the ability of a

given shovel dipper geometry to fill, within a set arc dig trajectory.

In comparison to the previous scale physical tests, a

good correlation to the DEM indicated that the numerical method was

able to mimic the dipper fill process; specifically particle flow mode

sand development of flow layers and particle obstructions, akin to

sanding in a low velocity hydro-transport pipeline.

Keywords: Rope shovel; Particle flow; Simulation; Discrete element method; PFC; Dipper

Introduction

A particle flow code (PFC) based discrete element

model (DEM) presents a viable tool to numerically model ground engaging

tool interactions; which may be used to mimic and predict complex

surface versus media concerns that are manifest as low productivity KPIs

[1].

Such DEM methods have been widely used to predict the flow behaviour of

rock materials for several decades, providing tangible solutions for

industrial and mining problems [2].

Coetzee et al. [1-5]

modeled the flow of broken rock particles into a dragline dipper using

DEM, proposing a means of estimating the input parameters required for

the modeling of cohesion-less material, where the size and density of

particles were assessed through direct measurement. Coetzee et al. [1-5]

showed that particles for a range of frictional and size

characteristics could be represented by clumps of varying size PFC

spherical particles interacting with one another. This early work was

verified through mimicking of a confined compression test [1]. However, Coetzee et al. [1,3-5]

concluded that although a general modeling trend was indicated, the DEM

was unable to predict the dragline bucket-ground interaction with the

anticipated accuracy[1,3-5].

Cleary [6,7]

in preceding the work of Coetzee et al. [1,3- 5], modelled the fill

process for a dragline dipper using DEM to compare the loading for

different dragline bucket designs, and to evaluate the loading impact on

the dragline bucket hoist and drag rope system. Cleary specifically of

interest for this paper, studied the effect of particle shape on fill

times and bucket fill volumes achieved, noting the two rock shape

parameters of aspect ratio and sharpness appeared to greatly influence

the behaviour of a particle’s ability to fill a dragline bucket [2,8], modelled via PFC encoded spheres and spherical based super-quadric hybrid shapes in DEM-3D [8,9].

Cleary’s results indicated that non-spherical particles showed more

resistance to flow, more representative of the friction resistance of

rock particles to flow resulting in lower fill factor payloads, but with

an increased fill time [9]. In parallel work, Owen et al. [10]

simulated a dragline bucket fill, where particles were modeled via

DEM-3D and the bucket load response was modeled via finite element

modelling [10], such that drag forces and trajectory distances were shown comparable with a scale physical test.

Following the work of Coetzee et al. [1,3-5], Cleary [2, 6- 9] and Owen [10],

this paper will show a parallel DEM application to investigating the

flow of broken rock particles into a rope shovel dipper, where there is

strong correlation to 1/32nd scale physical tests using a transparent

dipper and test bin, permitting the visual inspection of material

behaviour as previously reported by Rasimarzabadi & Joseph [11].

DEM as applied to a shovel dipper passing through a

digging medium, then employs two principal elements to define rock

particles and the shovel dipper rigid body; as spheres and walls

respectively [12,13].

In 2D simulations, a sphere is a stiff circle with unit thickness;

while in 3D simulations, a true spherical shape is defined [14].

To model non-circular (non-spherical) particles that may then be

attributed higher surface frictional properties, as might be expected

for highly angular broken rock fragments in a blasted rock file under

shovel dipper excavation; clumps of multi-sized spheres were used, where

a clump was a combination of two or more spheres that remained rigid

under all modeled conditions [14].

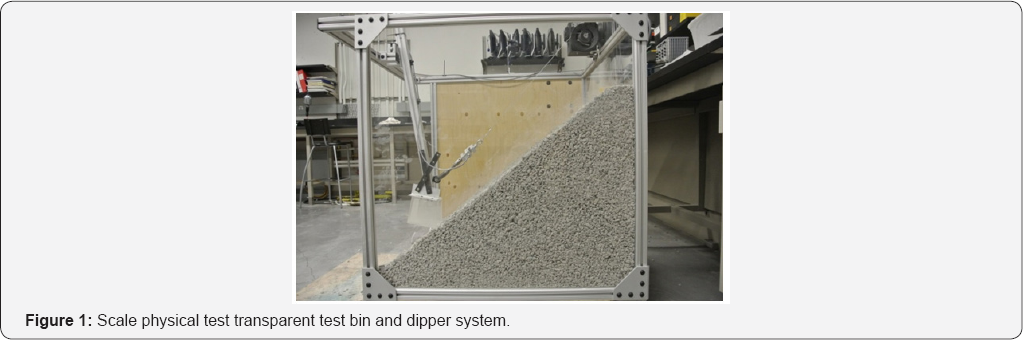

To provide a comparator and by extension a scaled

validation of the DEM numerical results, a set of scaled physical tests

were performed, after Rasimarzabadi & Joseph [11], using a transparent scaled rope shovel dipper and test bin arrangement (Figure 1). The scale testing was based on well accepted physical testing scaling laws as reported by Ghosh & Chakraborty [15].

The 1/32nd volumetric cube root scaled dipper model referenced a 44m3

ultra-class category field scale dipper found on Komatsu P&H4100 and

Caterpillar 7495 model electric rope shovels in common large scale

surface mine hard rock operations. The scaled dig medium was constructed

from crushed dolomitic limestone rock mimicking the field particle size

distribution relative to the shovel dipper geometry. As such, the field

mean rock particle size of 0.380.32m relative to a 44m3 capacity dipper

with a 3.58m wide lip set the 1/32nd scale 1,340 cm3 capacity dipper

with a 11 cm wide lip and 1.21 cm mean size broken rock. The dolomitic

limestone was chosen as it fractured under crushing producing similar

angularity and surface roughness commensurate with a field hard rock

blast excavation face.

The scale dipper hoist system was effected in a

similar arc trajectory to that experienced by the field rope shovel

system, relative to a 1/32nd scaled dig trajectory for the same dig

cycle time experienced in the field, such that a dig velocity range from

0.450.5 to 0.951m/s was then set at 1.41.6 to 3.03.1cm/s. The

transparent wear bin dig face height was also scaled from 12m in field

to 37.5cm in height at a similar angle of repose of 38, (Figure 1).

With all geometries scale matched from field to test scenario, the flow

mechanisms generated through the dipper to dig face interactions were

then commensurate with the field conditions, permitting high speed

camera visual observation of the particle flow characteristics into and

around the scale dipper as it passed through the dig face material.

Specific operation details for the testset-upmay be found in

Rasimarzabadi [16] and Rasimarzabadi & Joseph [11].

Defining Model Particle Material Properties

Although DEM simulation relies on micro- rather than

macro-properties of materials, where micro-properties of materials with

simple packing arrangements such as spherical contacts may be predicted

from material macro-properties; it is more difficult to determine broken

rock particle material properties, where arbitrary particle

orientations are present. In this instance, to assign appropriate

micro-property values for broken rick rock particles, calibration

methods are required; where density, particle shape, particle size

distribution, shear stiffness and friction define those micro-properties

[1,13,17].

For example, apparent (broken rock) density may be determined and used

as an appropriate particle density for PFC modeling purposes [18].

In DEM models, particles are represented by discs

(2D) or spheres (3D). Such particles do not represent broken rocks well.

However, DEM is capable of modeling particles with noncircular,

non-spherical shapes by creating clumps of discs or spheres of different

size and configuration [14].

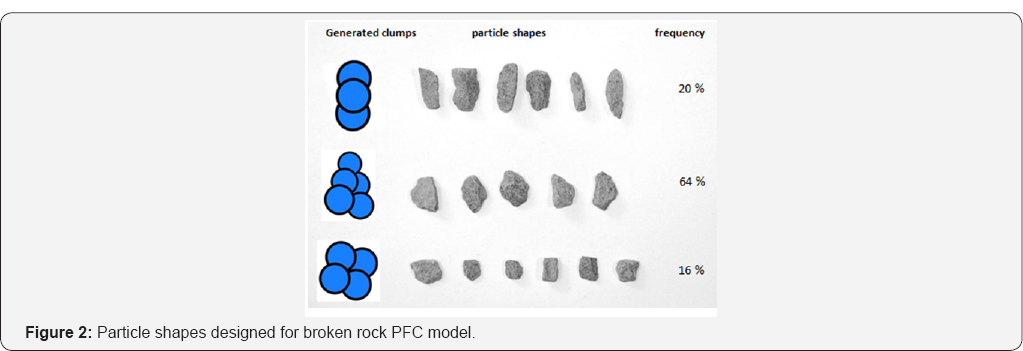

To determine the representative shape of particles commensurate with

that used kin the scale physical tests, a random sample of 250 particles

was taken from the dig face material. These particles were classified

into three groups based on their overall shape. For simplicity, where

complexity of modeled particle is directly proportional to computing

power needed to run a given model, the classification was restricted to

three clumped particles designed for PFC use. Figure 2 shows the three shapes designed to mimic the broken rock particles relative to frequency of occurrence in the dig face.

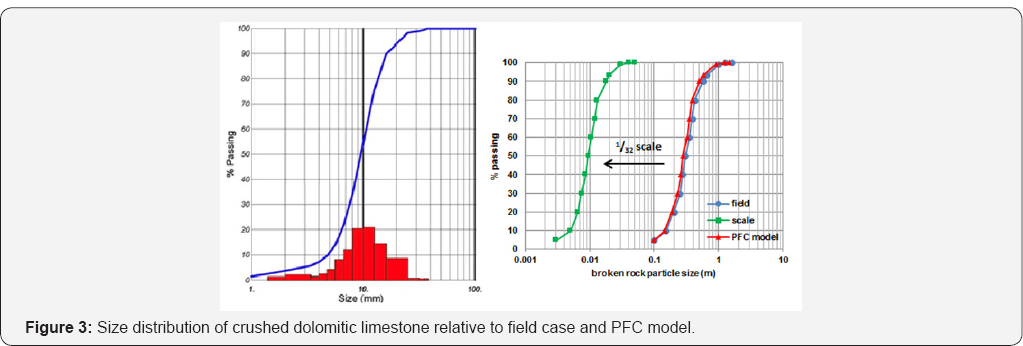

To determine the 1/32nd test size distribution for

the crushed dolomitic limestone, the digital image processing system,

WipFrag, was used, generating the distribution in Figure 3;

compared with the field dig face blast size distribution being mimicked

and the PFC model size distribution. A user defined FISH function was

written to model the scaled up results from Wipfrag, producing a

comparable match to the scale and actual rock particle distribution.

In order to estimate particle to particle model

stiffness commensurate with the actual material frictional and geometric

contacts, a simple packing simulation was conducted, where particles

fall into a container under gravity and settle to equilibrium. As such,

it was assumed that normal and shear stiffness were equal. The stiffness

model comprised eight containers filled with particles of similar

characteristics but different stiffness. The model was influenced by the

shape and size distribution of the rock particle fragments used in the

physical test.

In Figure 4,

container 1 presented the lowest particle stiffness, with large void

spaces. Increasing the particle stiffness in containers 2 through 8,

from left to right, it was observed that the height of particles in the

containers proportionally increased, resulting from decreased particle

overlap. It was also observed that a proportional change in stiffness

(columns 5 through 8), had a minimal impact on the change of particle

height in the container. Majidi [17]

argued that where stiffness change had a minimal impact, the particles

were then compacted with minimal overlap. To reduce the model

computational time step, a minimal value of stiffness was selected at

kn= ks = 1exp06.

The broken rock particle to particle friction

coefficient is a critical parameter in establishing the angle of repose

of the dig face in numerical modeling using PFC. Since the angle of

repose is a reasonable indicator of an effective friction co-efficient

for cohesion less broken rock fragments, the angle of repose was used to

indicate the friction co-efficient [19]. The dolomitic limestone particles used in the physical test were poured onto a horizontal surface, (Figure 5).

The pile conic angle relative to the horizontal was taken as the angle

of repose of broken material. For a number of piles, a mean angle of

repose was determined. The pile angle of repose test was simulated in

PFC2D for different friction coefficients, revealing outcomes comparable

to the physically measured angle of repose and focusing on an

appropriate friction coefficient value for simulating the dolomitic

limestone broken rock.

Frictional sliding between the components of a system

reduces the energy of the system; but frictional sliding alone is

insufficient to establish a state of equilibrium in a model [14].

Local damping and viscous damping are two options to reduce kinetic

energy in PFC; where local damping generates a damping force on each

particle that has a value comparable to an unbalanced force, while

viscous damping provides a damping force comparable to the relative

velocity difference between two particles in contact [14].When a system needs to rapidly reach an equilibrium state, local damping works best [13].

For systems with dynamic behaviour, or systems where particles are free

to move in the domain area, viscous damping is more suitable [14].

However, damping is a property that does not have a specific calibration method [13].

Here a set of test runs were conducted to evaluate different damping

coefficients. Analysis of the results implied that both local and

viscous damping was potentially needed. Viscous damping was a good

option for systems involving free flowing rock particles, as is the case

here; once establishment of the dig face file pile was achieved,

leveraging local damping to establish a reasonably steep dig slope angle

of repose. The local damping coefficient absorbed undesirable energy

generated when establishing the dig face pile as material dropped onto a

horizontal surface which under un damped conditions would generate a

low rock material angle of repose.

Processing Time

In DEM, the total processing time depends on computer

processor power. Long simulation periods revealed that it was necessary

to employ appropriate strategies to shorten total processing time. In

PFC, two parameters that may be manipulated to control simulation time

are the time step and cycle time [13].

The process duration, a function of the simulation setup and complexity of parameters, may be shortened by [13]

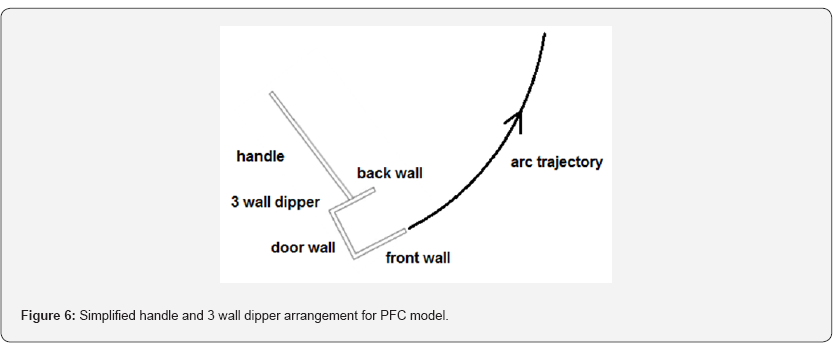

reducing the quantity of objects in the system, including modeling

spheres, clumps, and walls and reducing the time taken to generate the

rock particles and dig face from spheres and clumps. Here, the number of

calculations performed per cycle was reduced by decreasing the number

of rock clump particles and number of shovel dipper and dig bin walls in

the system. As such, the dipper was modeled as the simplest geometry

possible, Figure 6 and generation of highly complex particle clump shapes were avoided.

Generating a broken rockpile with a broad size

distribution of particle sizes and shapes adversely extended the model

computational processing time, given the large proportion of generated

clumps required in the system, thus limiting the number of runs

possible. As such, rather than generate the entire DEM broken rockpile

from clumps, the rock particle to dipper contact zone was focused as a

capping layer of set thickness over a set linear slope at the angle of

repose.

To further reduce the processing time, the time step

was increased. In a linear contact model, the time step is dependent on

particle stiffness, density, and size [13].

A lower stiffness results in a smaller time step; however, small

magnitude stiffness causes unrealistic overlaps between spheres and

clumps as evident from (Figure 4), [17].

It should be borne in mind that conversely a higher stiffness may also

result in unrealistic behaviour, due to high forces generated between

two particles in contact [17].

DEM Simulation Material Flow Into A Rope Shovel Dipper

Once the particles for the surface layer of the

rockpile were created, they were permitted to reach an equilibrium

state. The dipper was then created into the model using rigid walls,

initiated in the model at the toe of the rockpile. The dipper was then

moved through the particle layer by assigning a rotational speed to the

dipper walls. The motion behaviour of the particles and the loading flow

mechanism were recorded, and compared to the experimental test

observations reported by Rasimarzabadi & Joseph [11].

The results indicated good correlation to the dipper - material flow filling process seen in the physical tests [11].

It was specifically observed, as a qualitative key indicator of

modeling success, that as the dipper engaged the rockpile, a thin layer

of material flowed into the dipper (flow zone), with particles rotating

and sliding relative to each other. An increase in broken rock pile

penetration by the dipper, prior to moving along the trajectory path,

resulted in greater material being displaced and flowing into the

dipper, proportional to an increased thickness in flow zone.

As more rock particles entered the dipper, those

adjacent to the inner dipper walls, interlocked to particles that they

came into contact with, generating a bulk larger volume zone moving much

slower into the dipper, while the previously identified flow zone was

now forced to flow over the slower moving bulk zone. The closet analogy

to this would be 'sanding' in a slurry pipeline, where solids of larger

mass or density drop out of the main flow regime and create a

restricting pile in the base of a pipeline, impeding the ongoing flow of

a slurry. The simulation here clearly showed the mode of two motions as

the flow and bulk zones.

Observed both in the physical tests [11]

and in the model here, the flowing material into the dipper generated a

flow restricting pile, inside the leading edge (lip) of the dipper

front wall, which progressively increased in size through the dig cycle.

Given the progressively increasing restriction as the dig cycle

progressed along the dipper trajectory, a void space was generated at

the contact between the back and door walls of the dipper. As the

restriction increased in size, less material was able to progress in the

flow zone to fill the dipper, and hence the void space became

inaccessible to fill. In the physical test [11]

it was observed that the void space remained set to the point at which

the thickness of the flowing material over the bulk zone approached the

back wall of the dipper. In rotating the dipper as it proceeded to the

end of its trajectory and broke out of the dig face, the material

contained in the front of the dipper sloughed into the void space,

effectively transferring the void from backdoor corner to back-front

opening zone.

Although the numerical model was successful in

simulating the general flow pattern, it had some restrictions in

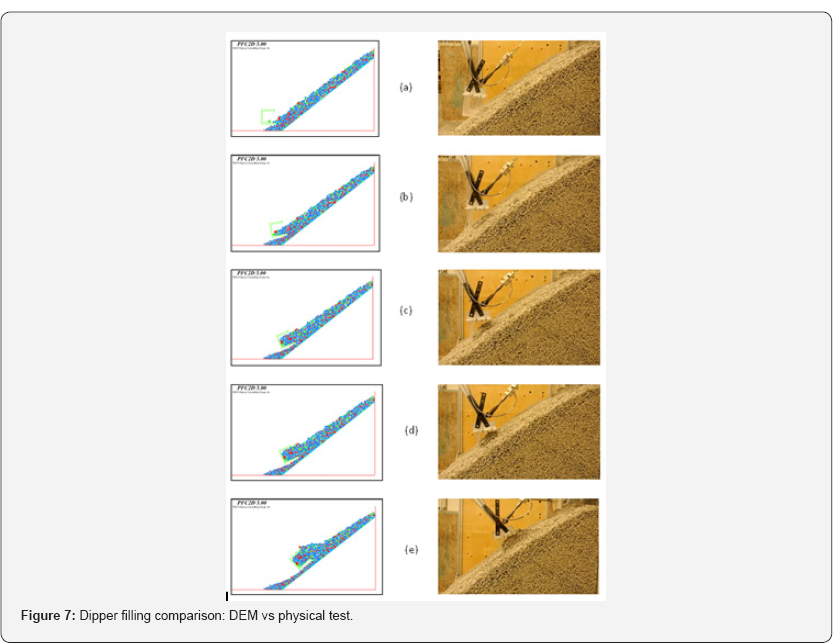

reproducing the physical test results. Figure 7 compares the results of the DEM model versus the physical test.

Figure 7a

shows the dig cycle initiation, where the dipper first engages the

broken rock dig face pile. The DEM seems to have reasonably simulated

this segment. Figure 7b

then illustrates the point at which the flow zone material contacts the

rear-door of the dipper. Although the height of material at the

dipper's ingress appears the same in the physical test and numerical

model, the particle slope forming inside the dipper appears more shallow

in the simulation.

In progressing through the dig cycle, a wedge of

particles inside the ingress at the front wall of the dipper is formed,

the thickness of which progressively increases, but again with an

apparent pile slope noticeably reclined in the numerical model. This

results in a much smaller void space developing at the rear of the

simulated dipper, Figure 7-c and Figure 7d.

As the thickness of the material obstruction at the dipper ingress

reaches the dipper back wall, the size of the void space in the DEM

model becomes insignificant Figure 7e.

The DEM model results did indicate that although the

simulated material showed the same flow pattern as evidenced by the

physical test results, it did not adequately mimic the void space

generation that consistently impacts fill factor for such shovel dippers

in industry. It is evident that the simulated particles moved past one

another with a much lower fictional resistance than anticipated, and as

such did not behave as angular, rough particles. This resulted in a

lower angle of repose pile of material developing inside the front wall

of the dipper, and a smoother flow of particles than the physical test

case, more easily able to fill the void space at the rear of the dipper

On reflection, the model was hampered by poor assumptions of particle behaviour

a. Roughness of particles: In an attempt to

generate rough particles via more complex clump geometries, the

computing power limited complexity. Simple clumps were chosen, but were

not complex enough to generate the roughness and friction response

expected. As surface roughness increases, the value of the

inter-particle friction coefficient increased which lead to reducing

rolling ability and increased interlocking; where as smooth particles

were able to move past one another via sliding and rotation with only

limited resistance.

b. Friction coefficient: The inter-particle

friction coefficient defines how difficult it is for the particles to

move over one another. Too low a particle friction coefficient results

in particles moving easily over one another and permits the dipper

structure to penetrate deeper into the dig face material. The friction

coefficient in the PFC model was determined from the angle of repose

calibration. However, higher friction coefficients were examined showing

that an increase in friction coefficient had no significant influence

on results. It is believed that the impact of the particle shape,

representative of the roughness of the particles, was more significant

than the value of the friction coefficient used in the model.

Contact and damping models: PFC is primarily employed

for static systems. Employing these methods in dynamic models may

generate unforeseen issues [13]. Different damping values were examined and those that worked best with the model were selected.

Compaction and rock particle interlock: The PFC

method used to generate the dig face broken rock resulted in a low

degree of particle interlock and effective material compaction; which

decreased the effective frictional resistance to a dig implement. The

major obstacle in this study was to create a representative broken rock

dig face.

Understanding the Void Space in the Dipper

The major difference between the numerical model and

the physical test observations was the degree of generation of void

space at the back wall - door wall contact of the dipper. Due to the

importance of understanding the generation of this void space, further

simulations were performed to investigate the capability of DEM to model

such a phenomenon. Shi [20]

previously stated that in rope shovel dipper operation, the void space

is generated at the end of the dig cycle, located at the leading edge of

the dipper back wall. Shi [20] was however not aware of the filling mechanism that gave rise to the initiation of the void space.

To improve the PFC DEM model with a greater effective

friction restricting the flow of particles into the dipper, previous

research indicated that a mixture of fine and coarse particles reduced

particle resistance to move relative to one another due to the

lubrication influence of finer particles [21-23].

The revised simulation model replaced the previous uniform size

distribution with a broader range of larger rock fragment material

sizes.

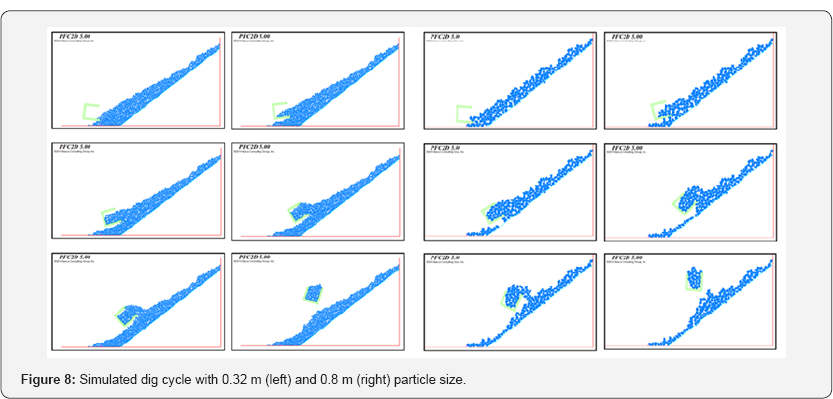

While the revised simulations were performed with

different particle sizes; other properties were kept constant. Particle

sizes of 0.152m, 0.32m, and 0.8m, were trailed effectively representing

small, medium, and large particle sizes, the latter medium and large

sizes reflected in Figure 8.

For the smallest particle size modeled at 0.152m, the same smooth flow

of material as originally modeled with the broad size distribution

evident in Figure 7

was discerned. In the small particle size case, little digging

resistance due to a low friction coefficient was evident. Under such

conditions, there exists a low likelihood of void space generation in a

dipper, corresponding to a high achievable payload.

Figure 8 shows

that by increasing particle size, the void space generated during the

dig cycle also increases. Common with the results of the physical scale

tests, the void space develops as the ingress of the dipper is blocked

by incoming material. In Figure 8,

rotating the dipper orientation at the end of the dig cycle caused the

particles to fill the void space and generate a new void space at the

front of the back wall, transitioning the void space to its final

location, as was commented on by Shi [20].

Figure 8

which also shows large 0.8m particle sizes, illustrates that even in

rotating the dipper orientation, the material is unable to flow into the

void space of the dipper due to more pronounced particle to particle

interlocking, so the void space can be seen maintained in the same

position to the end of the dig cycle. This is what would be logically

expected for very large particle sizes.

Modifying the properties of the simulated

particles in the DEM model produced results that were more

representative ofthe physical test experience. The void space phenomenon

realized in the model represented in Figure 8 is significant; as it represents the physical test evidence of Rasimarzabadi and Joseph [16],

as a previously unknown dipper fill phenomenon. This knowledge now

provides the impetus for dipper manufacturers to review dipper designs

with the goal of negating a void space generation during the fill cycle.

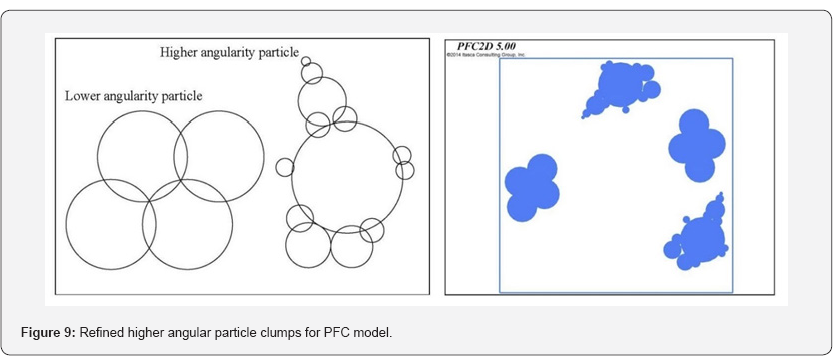

To generate particles with higher frictional

resistance capable of giving rise to a steeper dig face pile, particle

shapes were constructed to represent moderate and high angularity

materials, Figure 9.

This was in turn varied via particle sizes of 0.32, 0.8, and 1.2m, then

termed small, medium, and large particles, relative to the ingress

across the lip system of the dipper, where the largest particle size

passing was rated as being less than 1/3 of the dipper lip width, such

that for a 44m3 'box' shape dipper the largest particle size is

estimated at 1/33^44 equivalent to 1.18m.

Dig piles were created using the clumps shown in Figure 9 representing

moderate angularity for the three different particle sizes with the

overall size distribution commensurate with the physical scale test

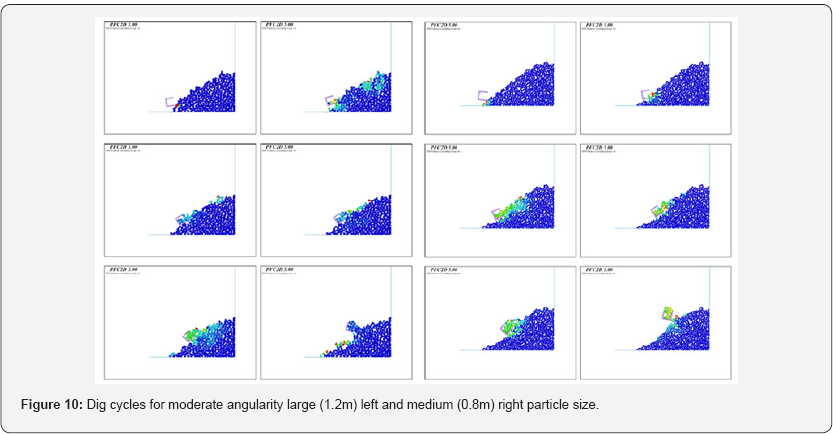

material and field conditions. Figure 10

illustrates sample dig cycles for the large (1.2m) and medium (0.8m)

particle sizes, where the blue to red colouring indicated zero (blue) to

high (red) levels of induced particle motion due to the dipper - ground

interaction.

As previously reported through the physical test results [16],

the general particle fill flow was similar for all examined particle

sizes; but the size of particles did impact dig efficiency; a function

of the steepness of the dig face as the angle of repose, increasing with

increasing particle size.

In Figure 10

(left) where the large particle size was roughly equal to 1/3 of the

dipper lip width, at 1.2m, it is evident that during the first half of

the dig cycle large particles blocked the dipper ingress restricting

further particle flow into the dipper. However with changing the

orientation of the dipper, gravity assisted obstructing particles moving

further back into the dipper, thus permitting more material ingress.

The medium 0.8m particles in Figure 10 (right) had little difficulty in flow into the dipper, reflective of an easier set of dig conditions.

As previously seen in the physical tests [16],

a void space was evident in all simulations, but the void space size

reduced with decreasing particle size. Commensurate with a smaller void

space, as would be expected, the overall final dipper fill suggested a

higher payload with smaller particle size and less likelihood of dipper

ingress restriction. The results then indicated that particle size has a

significant influence on loading action, highlighting the importance of

blast fragmentation for excavating application.

The issue with blast fragmentation prediction is that, as illustrated in Figure 11, there is frequently an over-estimate of smaller particle size fractions compared to actual distributions inset from Figure 3. The Kuznetsov-Rosin-Rammler fragmentation model shown in Figure 11 was

generated for a dolomitic limestone modulus of 15 GPa commensurate with

field conditions, where a 6.25 m burden by 9 m spacing blast pattern of

235 mm diameter blast holes were loaded at 8.5 m charge length with

emulsified 1.17 relative strength ANFO explosive for a 13 m bench

production blast at a powder factor of 0.62 kg/m3. Although there is

evidently a different size distribution particularly with reference to

smaller particle sizes, the maximum size of 1.18 m for the shovel dipper

was approached, and the d50 50% passing characteristic size fraction

was the same at 0.3m. As such a combination of existing blast

fragmentation analyses combined with the DEM model observations in this

paper provides a useful tool in predicting shovel dipper interactions

with fragmented rock.

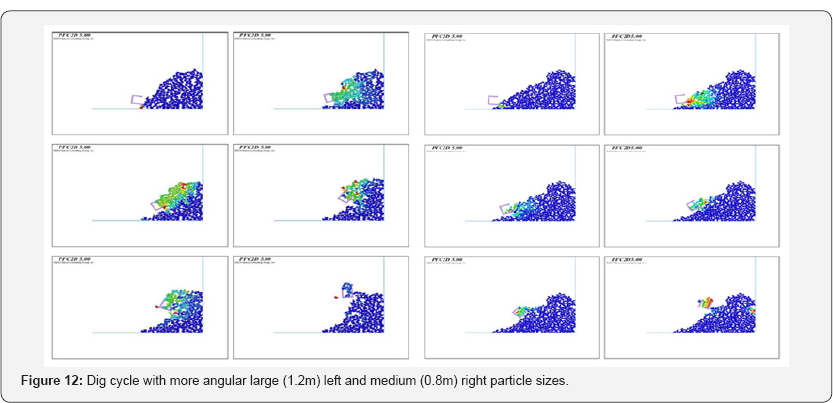

To further investigate the influence of particle

shape, specifically particle angularity on flow pattern, a model was

generated using high angular clumps, Figure 12 then illustrates the results for the medium and large particle sizes.

Effectively the higher the angularity of the

particles, the steeper the dig face pile, with the more angular

particles showing a greater tendency to block the dipper ingress and

promote a dipper internal void space. Figure 12

clearly shows an ingress restriction from the onset of the dig cycle.

It is evident that as angularity increases, particles cannot easily pass

one another and become interlocked, effectively requiring that

particles overcome a higher frictional resistance due to rolling

limitation.

Conclusion

A series of DEM simulations were performed to

evaluate the dynamics of filling a rope shovel dipper and investigate

the capability of DEM against physical test evidence commensurate with

field conditions.

The modeling results showed the DEM simulation was

able to mimic the broken rock particle flow noted from the physical

scale tests.

The DEM simulation was shown to successfully model

the flow of broken rock particles into a rope shovel dipper, predicting

many of the trends seen during scale physical testing. The flow

mechanism stages including particle flow layers identified in the

physical tests were identifiable in the numerical simulation. The

process of void space generation inside the dipper was clearly evident

in the numerical simulation once the particle size, surface angularity

and roughness; proportional to frictional resistance and angle of

repose; were delineated through particle shape refinement in the DEM. It

was specifically observed that the more fluid a digging condition

observed in the simulation output, the lower opportunity to generate

void space was evident, proportional to the quality of rock blast

fragmentation.

For More Open Access Journals Please Click on: Juniper Publishers

Fore More Articles Please Visit: Civil Engineering Research Journal

Fore More Articles Please Visit: Civil Engineering Research Journal

Comments

Post a Comment