Experimental Evaluation of Gravel Bed Up-Flow Roughing Filter for Pre-Treatment of Rural Community Water Treatment- Juniper Publishers

Juniper Publishers- Journal of Civil Engineering

Abstract

Water is essential for life. This study evaluates

gravel bed up-flow roughing filter (URF) for pre-treatment of rural

community water treatment. The pilot unit consisting of acrylic pipe

with internal diameter 90mm was used for study. This column is

vertically fixed, having an inlet at bottom so that filter can be run

for up flow mode of operation. For sake of roughing filtration,

artificial raw water was continuously passed through laboratory column

packed with quartz gravel media. Media size range was 16mm-2.36mm. The

media was filled in the column in three layers. Filter was studied for

the flow rates in the range of 5-20m/hr. The results investigated shows

that turbidity removal by gravel bed roughing filter is very good it is

almost 85% - 90%. By and large, based on the present experience of the

different filtration experiments it can be certainly inferred that the

URF is a dependable alternative for conventional pretreatment of water

in rural community water treatment.

Keywords: URF; Rouging filter; Water treatment; Gravel media

Introduction

The development of human settlements cannot be

assured without securing and maintaining an adequate supply of water.

Naturally availed water can contain a wide range of ingredients that can

make people awkwardly ill or make it unsuitable for certain

applications. So, ensuring appropriateness of water in view of a

proposed use is an inevitable task. The necessity of water purification

was understood by man at the very outset of civilization. Wholesome

water is one which is safe, potable, and contains essential nourishing

minerals in adequate quantity. So the quest for progressively better

water continues.

However, an increase in manmade water pollution, the

development of technical and public health science, as well as the

consumer’s greater need for clean water contributed to the development

of the water purification technology [1].

Water, as required for the life, is rarely available

in the natural world. Therefore, wide arrays of treatment procedures are

evolved to cope up with different quantities, initial qualities, and

finishing requirements of water to be treated. In the present day, the

main objective of water treatment facilities in India is to produce safe

and potable water. With ongoing development of the country it will be

obligatory to address the issues related with safe, potable and

wholesomeness of water to be supplied and sustainability of treatment

procedures to be followed.

Contemporary water treatment technology is the

outcome of vigorous and systematic efforts of scientists and

technologists, working for more than last hundred and fifty years.

Surface water assumed the status of prime source of water as it is more

suitable for the use, and easier to treat in comparison with water from

other sources such as ground water or sea water. So, from the 1850s to

about the 1950s, water treatment facilities were frequently designed by

experienced engineers using empirical rules and succeeded design

practices. However, after the 1950s, a greater understanding of

fundamental principles underlying treatment processes was required to

deal with complexities due to growing demand for water, and increased

pollution of water bodies.

Pretreatment comprising of coagulation, flocculation

and sedimentation is known to be essential for rapid sand filtration. It

is because pretreatment not only trims down the particles but reduces

the surface charges of micro flocs to be removed by final filters.

However, the conventional pretreatment is costlier in view of large

capital as well as operation costs. Therefore, there

is a need for alternative pretreatment methodology to replace

conventional pretreatment units. Roughing filtration (RF) are low-cost

primary treatment options that could potentially improve the water

quality. The goal is that the primary treatment reduces the turbidity to

be within the 5-10 NTU range or lower so that RSF can be effective.

A roughing filter can effectively remove

colloidal-size particulates without the addition of coagulant chemicals

and also provide a large solids storage capacity at low head loss.

Sedimentation and adhesion to media particles are the main particle

removal mechanisms [2].

So, Roughing Filtration could be considered as dependable technique for

pretreatment. Subsequent to study of many water treatment plants in

India, CPCB [3]

reported rather inadequate pretreatment at many plants. It is reported

that chemical feeding is unsatisfactory, flash-mixers are defunct and

settling basins are overloaded. The use of roughing filtration would

obviate need of flash mixers and settling basins.

Depending on the rate of filtration, filters can be

classified as slow sand filters, rapid filters, or high rate filters.

Due to common availability, sand and gravel are the most common granular

media. Mono-medium, dual media and multimedia filters are also

developed to enrich the filtration process. Direction of flow during

filtration process results in different types of filters as down flow,

up flow, horizontal flow, radial flow and bi-flow filters. Filters

utilized in water treatment are also classified as gravity or pressure

filters based on driving force. Pre-filters or roughing filters

primarily aim at removal of impurities basically larger in size and

provide pretreatment to reduce the load on final polishing filters.

Significant aspects, design and operational parameters of the commonly

used of filters and roughing filters are provided in Table 1.

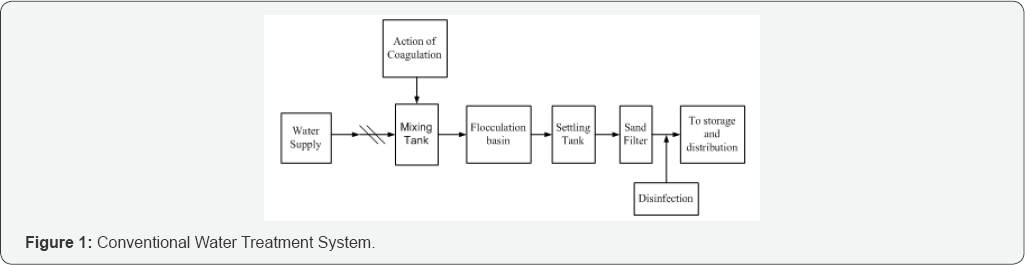

Conventional Water Treatment Units

In reference [4,5]

the primary purpose in surface-water treatment is chemical

clarification by coagulation and mixing, flocculation, sedimentation,

and filtration. These unit processes along with disinfection work to

remove particles, naturally occurring organic matter (bacteria, algae,

zooplankton, and organic compounds), and microbes from water to produce

quality water that is noncorrosive. Specifically, coagulation and

flocculation work to destabilize particles and agglomerate dissolved and

particulate matter. Sedimentation removes solids and provides virus

removal. Filtration removes solids and provides 1-log virus removal.

Finally, disinfection provides microbial inactivation and 2-log virus

removal Figure 1.

Simply stated, water primary treatment is any

physical, chemical, or mechanical process used before main water

treatment processes. It can include screening, pre sedimentation, and

chemical addition.

Non-Conventional Pretreatment Units

The electro coagulation floatation process consists

of electrolytic reactor with aluminum electrodes and a separation

floatation tank. The colloidal particles present in the water are

subjected to coagulation and flocculation by aluminum ions dissolved

from the electrodes. Hydrogen gas generated at cathode floats the flocs [6].

Performed experiments on laboratory setup and concluded that

electro-coagulation performed better than conventional coagulation with

aluminum sulphate for treating a model colored water, 20% more DOCS was

removed for the same Al dose.

Kardile [7]

has worked on a new unconventional treatment plant at Varangaon. The

system was designed for daily water supply of 4.20 MLD. He introduced

gravel bed flocculation unit of 3m*3m*2.5m in water treatment plant.

Gravel bed flocculation provides a promising solution to replace

mechanical flocculation unit for treatment of turbid water sources for

small capacity plants.

Bhole et al. [8]

have introduced "New concepts in low cost treatment plants". They

conducted experiments on pretreatment unit which combines principles of

tapered velocity gradient flocculation and solids contact flocculation.

Background on Roughing Filtration

Wegelin [1]

points out that roughing filtration is a process for separating

suspended impurities from water by passing through porous media.

Particle removal is one of the main objectives of filtration. Gravel

filtration has been used in water treatment since the early 1800s, when

it was first used in Scotland to pre-treat water prior to sand

filtration. Gravel filtration soon disappeared due to the advent of

chemical and mechanical water treatment. However, gravel filtration

reemerged in the 1970's and 1980's mainly in developing countries as

roughing filters, because those roughing filters do not require

sophisticated mechanical equipment or the use of chemicals.

Wegelin [1]

mentioned, roughing filtration technology is used as primary treatment

to polish the raw water quality for the improvement of performance of

slow sand filtration. But it may be used without slow sand filtration,

if raw water originates from well protected catchment area and having

minor bacteriological contamination. Therefore in rural water supply

systems roughing filtration becomes an appropriate technology.

So far theory of roughing filtration is not amply

established as the roughing filtration is not employed widely. It is

being considered as a remedial measure to reduce turbidity of water to

be applied to slow sand filters. Presently, the slow sand filtration is

almost abandoned in view of increased water demand and large area needed

for it. However, the roughing filtration could be employed for rain

water harvesting as well as an alternative for conventional

pretreatment. Ease of operation and maintenance in roughing filtration

makes it appealing for small capacity water treatment plants in rural

area.

As the pore sizes in roughing filter media are quite

larger than media in all other granular filters, head-loss developments

are smaller and the filter can run for more duration. So, the

regeneration is required less frequently. However, the regeneration of

roughing filter is rather distinct in comparison with other granular

filters. The larger media grains need too large flow rates for

fluidization. So, the cleaning by draining the bed is adopted at many

places. Smaller gravel in roughing filters could be cleaned by fluidized

washing. Suitable techniques could be appropriately combined to

regenerate roughing filter as and when required.

Materials and Methods

In pursuance of set objectives for the present work, laboratory experiments were planned and performed.

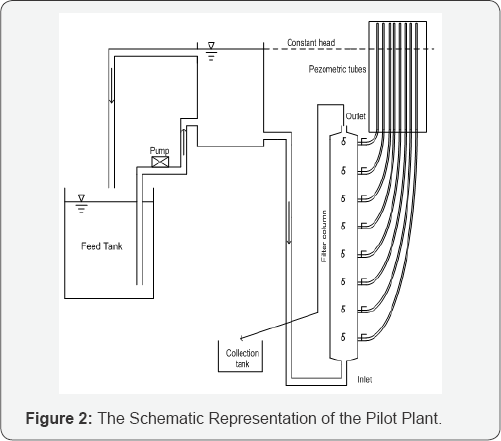

Figure 2 shows the schematic representation of the pilot plant unit and Figure 3 shows an actual picture of the filter unit.

Experimental setup

Filter column: The filter column used for

laboratory experiment is an acrylic pipe with internal diameter 90mm.

This column is vertically fixed, having an inlet at bottom so that

filter can be run for up flow mode of operation. For sake of roughing

filtration, artificial raw water was continuously passed through

laboratory column packed with gravel media.

In order simulate field conditions constant head tank

is provided. The artificial influent from feed tank is pumped to the

constant head tank. The overflow from the constant head tank is allowed

to pass into feed tank. So, the artificial clay suspension in feed tank

was in incessantly stirring condition due to pumping and recirculation

from constant head tank and there was almost

no settling in feeder tank.

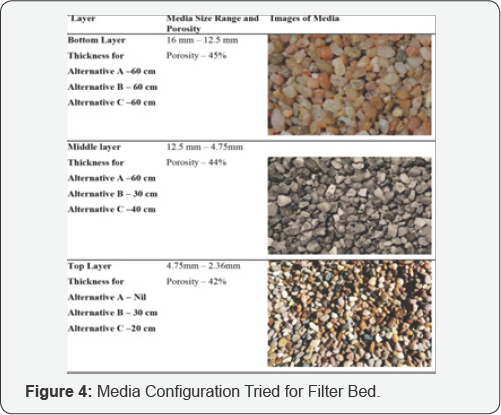

Filter media: Media used for filter bed is quartz gravel

Media size range was 16mm-2.36 mm. Stratification and configuration tried was as shown in Figure 4.

The media was filled in the column in three layers. Prior to packing

each layer in column, filter media was washed thoroughly with tap water.

Media was packed in the column in 5 cm increments and tamped down before

pouring additional media. After each layer of filter media a temporary

perforated plate was placed on and pressed tightly against the top of

the filter media.

Head loss and sampling ports: The filter

column has 8 sampling ports as well as 8 ports for determining head loss

at various depths of media. The inlet port is at bottom and first

sampling port is provided at a distance of 20cm from inlet port and

other successive ports are arranged accordingly. The seventh port is at

the top of the filter followed by output.

Flow control arrangements: A centrifugal (0.25

hp) pump is used to pump the influent water from the feeder tank to the

constant head tank. Constant head arrangement is provided by allowing

overflow from constant head tank. The overflow from constant head tank

is again directed to the feeder tank.

Flow rate arrangements: The filter was run at the constant flow rate. A flow control valve at the outlet of the column is used to control of flow rate.

Characteristics of water used: For the present

study, bore water and river bank clay was used to prepare artificial

influent. The bore well water was used for fluidized washing as well as

for Back-flushing the filter bed as and when required.

Suspension of river bank clay: For the

experimental study, artificial turbid water prepared in laboratory was

used. The turbidity was created by adding river bank clay to bore well

water. Prior to each experiment, the clay was hydrated in bore well

water overnight, dispersed in a blender, and mixed with additional water

to the desired initial turbidity.

Coagulation: Alum was used as coagulant. The

stock solution of alum was prepared in distilled water. It was added in

feeder tank in predetermined doses and mixed thoroughly every time while

preparing influent as desired for each set of filtration experiment. As

overflow water from constant head tank was recirculated into feeder

tank, there was continuous agitation and the possibility of settling of

particles in the tank was reduced. Further the stirring condition also

helped for better mixing of coagulant with raw water. The doses were

determined by conducting standard jar test.

Measurements of parameters

Turbidity measurements: Removal efficiencies

for all experiments were based on turbidity measurements (NTU). All

turbidity measurements were directly done, using a digital turbidity

meter of Hach make (2100P Portable Turbidimeter).

Flow rate: Flow rates were determined by

collecting effluent in calibrated jar and recording time required for

collecting 1 L of effluent in the jar. Flow rates were determined at the

predetermined time interval i.e. every one hour.

Head loss: The head loss measurements were

carried out and recorded at every hour and at all ports of filter

column. Piezometric tubes were used to measure head at each port.

Results and Discussion

Various filtration experiments were conducted in

order to acquire experience regarding performance of the roughing

filter. The observations made are put forth in this chapter along with

the discussions and significant findings.

Design of experimental set-up and operational parameters studied

Design of experimental set-up and operational

parameters are of immense importance in the study as they determine

rationality of findings based on the study. So, the design of

experimental set-up and operational parameters were carefully

considered.

Filter bed adopted: The configuration of

filter bed is the essence of all filtration processes. The

characteristics of filter media and depth of filter bed govern the

crucial parameters. The quartz gravel was used in the present study. In

line with the aim of pre treating the turbid water the coarser media

(2.36mm- 16mm) was selected unlike the finishing filters where effective

size of sand used is about 0.5 mm. As in the present study the URF was

challenged with coagulated and flocculated influent the largest gravel

size adopted was 16mm.

The stratified filter bed was adopted unlike the

finishing filters wherein un-stratified bed is deployed. For finishing

filters stratified bed are avoided in order to get rid of intermixing at

the media interfaces which can produce higher head losses. Further

highly fluidized washing of URF is to be never tried due to larger media

grains which require unworkably large fluidizing velocities. So, the

stratified bed was adopted with three different layers with gravel size

ranges as 2.36-4.75mm, 4.75-12.5mm and 12.5-16mm. The layer depths were

optimized to avail optimum removal performance as discussed in

subsequent sections. The total depth of 1.2 was adopted in the present

study.

Flow rates rtudied: The flow rates to be

deployed depend on target effluent, quality of influent, and more

crucially on economic feasibility. Good quality of target effluent and

poor quality of influent demand lower flow rates whereas greater

economic feasibility would demand higher flow rates. In this view the

flow rates in the 5-20m/hr were tried in the present study. Earlier

studies for roughing filtration are carried out even with flow rates of

1m/hr for pretreatment of water to be applied on slow sand filters

Wegelin [1].

Considering increased water demand, the aim to accomplish only

pretreatment, set target turbidities and more decisively economic

interests the flow rates adopted in the present study could be

proclaimed to be appropriate.

Optimizing filter bed configuration

For finding optimum media configuration, different

combinations of different sizes of gravel media were tried. The total

depth of media in URF column was 120 cm as aforesaid Wegelin, [1]. The different configuration of media as considered in alternatives A, B. and C were tried (Figure 4).

The filter runs were conducted with influent turbidity of 20-100NTU and

a coagulant dose of 5-40mg/L. Constant flow rate of 15±0.4m/ hr was

applied. It is desired to have effluent turbidity below 10 NTU.

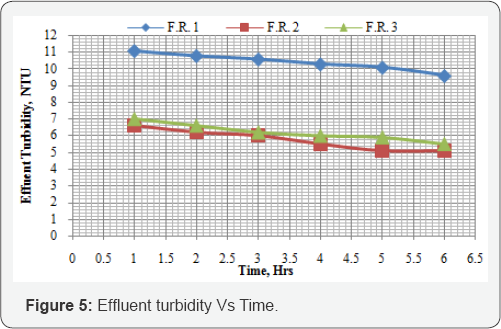

Although effluent turbidities observed for the

alternative B, are superior to some extent for all filter runs, the

total head- losses for the alternative B are significantly larger. The

head losses after6 hr for the alternative B is 40-55% larger than for

the alternative C. So, the configuration - alternative C is considered

as the best configuration as the removal efficiency was as desired and

head- loss development was considerably less in comparison with the

configuration alternative B (Figure 5).

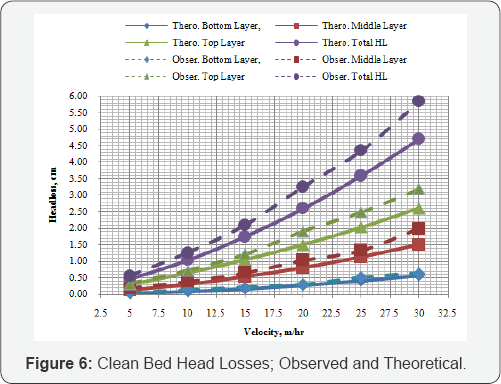

Clean bed head-losses

Clean bed head-losses, also known as initial

head-losses are amongst the significant hydraulic focuses that are

relevant to design of filtration systems. Depth-wise initial head-losses

are informative in respect of stratification of filter bed. Further,

initial head-losses influence the head available for actual filtration.

Initial head-losses across the filtration system are inclusive of losses

in the system without filter bed i.e. piping with accessories and

filter bottom with under-drains. Therefore they are also useful to

evaluate system components other than the filter bed.

These losses are found to vary nonlinearly and are

directly proportional to flow rate. The clean bed head-losses for the

URF layers with larger media grains were lower than that for layers with

smaller media grains due to larger grain sizes and porosity of the UF

filter. Theoretical clean bed losses, calculated using Ergun's equation,

are compared with observed head losses.

The observed initial head-losses for different flow rates, at different depths of sand beds are plotted in Figure 6 the

depths considered are measured in the direction of the flow through

gravel media. The observed initial head-losses are marginally higher

than computed head-losses for all layers as apparent from Figure 6.

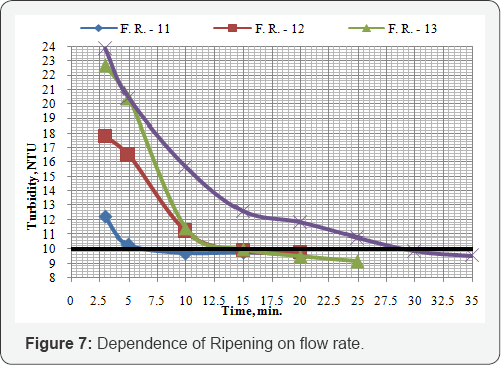

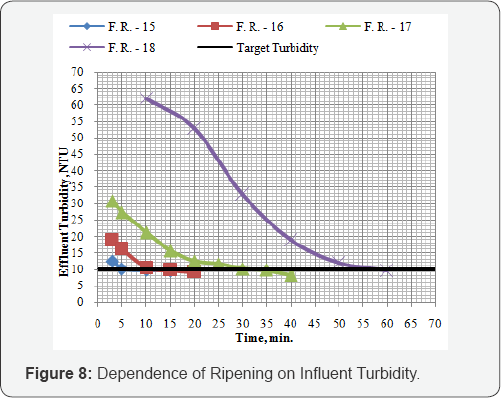

Ripening behavior of filter

This first stage of maturation of filter is known as

ripening. During the process of ripening the clean filter bed gets

conditioned due to attachment of particles from influent. The removal

efficiency of a filter continues to improve as the deposits build up in

media during ripening period.

In general ripening periods observed for URF are

15min- 1hr. Similar to those for finishing filters (15min-2hr). Though

grain size in URF is large ripening periods are comparable with drinking

water standards [9] As seen from Figure 7

the ripening of URF is dependent on filtration rate which corroborates

with the earlier research on ripening of rapid sand filters, Cranston

and Amirtharajah [10].

So, in order to deal with inadequate effluent during ripening period it

advisable to recirculate the inadequate effluent and to provide

multiple units of URF operating in staggered manner Figure 8.

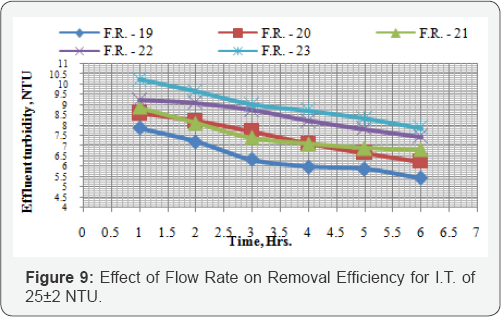

Effect of flow rate on removal efficiency and head loss development

For determining optimum flow rate for URF, removal

efficiency and head loss development are crucial. Hence, the filter runs

on URF were carried out to study effect of flow rate on removal

efficiency and head loss development. URF was run for 6hrs. Flow rates

were varied from 520m/hr and different influent turbidities were tried

(25-100 NTU) with the respective coagulant doses. It was desired to have

effluent turbidity below 10 NTU.

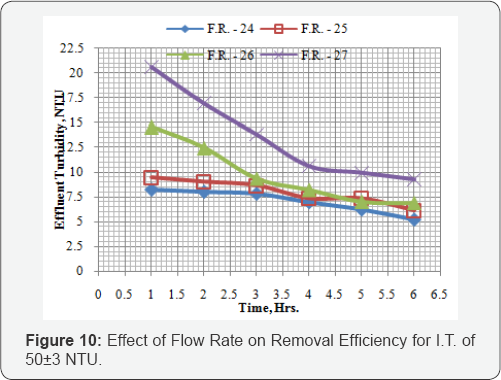

Observations for influent turbidity 25±2 NTU and 50±3 NTU are illustrated in Figure 9,10.

In general it is found that with increase in flow rates removal

efficiencies reduce and head losses increase. Since desired turbidity is

10 NTU and URF is found to take more than reasonable time for ripening

at higher flow rates. So, for higher turbidities the only option is to

run the URF at lower rate (5m/hr.). However such higher turbidities are

for very small period during the year. For the normal turbidity as seen

from the different runs discussed earlier, flow rate of 15m/ hr. is

found to be reasonable in order achieve desired removal performance.

With this flow rate, filter will generate more amount of effluent/sqm,

so that, overall cost of treatment will be more affordable.

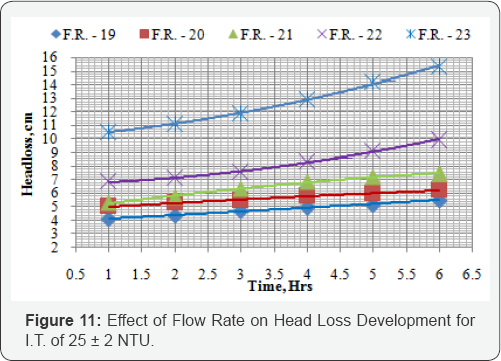

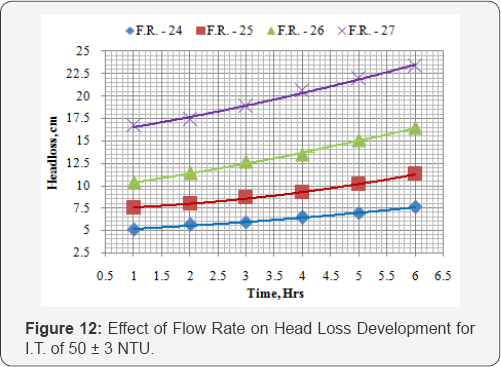

Observing Figure 11,12 it

can be seen that for smaller flow rates i.e. 5m/hr and 10m/hr head

losses are low enough whereas for higher flow rates, like 20m/hr and

above, head losses are too high. Keeping in mind head-loss development

too, constant flow rate of 15�0.4m/hr is recommendable for URF.

Performance evaluation of URF with optimal design and operating parameters

To evaluate performance of the URF unit, effluent

turbidities and head losses at different level and at different time

intervals are very expedient. Further, an experience of long duration

runs is essential for advocating the technique for field use. Keeping

this in mind the URF was run for longer duration and turbidity and

head-losses are monitored at different levels and periodically by

collecting samples at the sample ports. The filter runs were conducted

with influent turbidity of 20-100NTU and a coagulant dose of 5-40mg/L.

Constant flow rate of 15±0.4m/ hr was applied. It is desired to have

effluent turbidity below 10 NTU (Figure 13-15).

The port wise turbidities were monitored during

filter run (F. R.) with influent turbidity 20±3NTU. Constant flow rate

of 15±0.4m/hr was employed. The F. R. was carried out for 19 hrs. The

average effluent turbidity obtained was 4.2 NTU. So, the removal

performance was good enough in view of target turbidity set (10 NTU).

The total head loss developed was 22.5cm after 19 hr therefore the run

could have been extended further, as the effluent turbidity was also

significantly less than target turbidity.

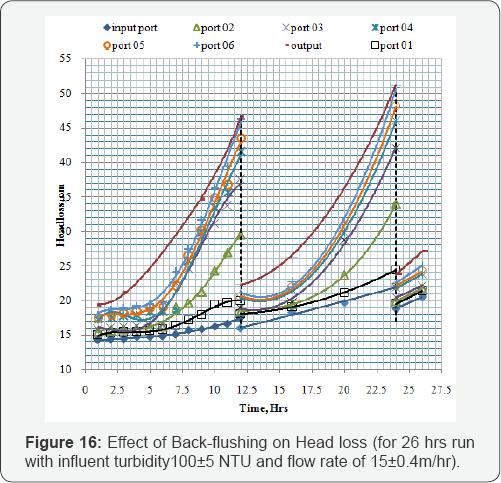

As seen from Figure 16,

it can be understood that turbidity removal is throughout filter depth,

though it is more significant in middle lower portion of total media.

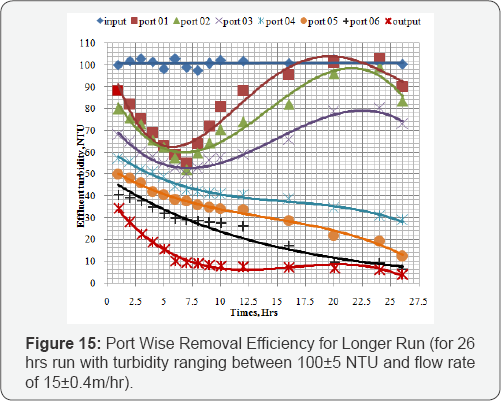

For some other F. R., URF was operated for duration

of 26hrs; and during this time interval port wise turbidities were

monitored (Figure 15).

Back flushing was adopted after ever 12 hrs for improving performance

of URF for this filter run. While operating this filter run influent

turbidity of 100±5 NTU and constant flow rate of 15±0.4m/hr was

employed.

Observing trend of turbidity removal in this filer

run, it can be understood that after each back flushing interval (i.e.

every 12 hrs) there is moderate change in removal efficiency of URF.

However, as filter run proceeds turbidity keeps on decreasing. The Figure 16

gives relationship between head loss and time. Here also effect of back

flushing can be seen notably. After each back flushing phase there is

fall in head-loss and gradually it increases. The recovering of utilized

head has significantly positive impact since it helps in extending

duration of filter run and periodic back-flushing assists in keeping the

bed reasonably clean. At the end of the filter run maximum head loss

observed after 26hr was just 27.1cm. Periodic back flushing is required

to prevent heavy accumulation of solids in the roughing filter. This

will reduce deterioration of effluent due to detachment and in

minimizing head losses too.

Conclusion

Based on the present study, it is feasible to render

certain inferences regarding behavioral aspects of URF, deployed as an

alternative for pretreatment of water. Further, the recommendations for

design and operating parameters for URF are also put forth based on the

experience of performance URF.

General features of URF

o Up flow roughing filtration is found to be viable

for pretreatment of water. The URF is found to function consistently for

long duration without special requirements of operating skills. So, the

present study corroborates its deployment in rural water supply schemes

where treatment plant capacities are small; and skilled operators not

available.

o The URF demonstrated true depth filtration as head

loss developments were moderate and there was no incidence of clogging

of the bed.

o Clean bed head losses are insignificant in URF due

to large grain size and porosities. Theoretical head losses computed

using Ergun's formula, are comparable with observed head losses.

o The initial effluent quality was found to be poor

during ripening. Ripening periods are found to be reasonably smaller

(3min) for lower flow rates (5m/hr) and lower influent turbidities

(26±0.5). Ripening periods are found to be larger (60min) for larger

flow rates (20m/hr) and larger influent turbidities (100±1).

o Head losses in URF during operation are inversely

proportional to flow rate and directly proportional to influent

turbidity. However, the head-loss development in UFR is moderate due to

large grain size and porosities. In general head loss is not the run

termination criterion for URF.

o influent turbidity. However, the head-loss

development in UFR is moderate due to large grain size and porosities.

In general head loss is not the run termination criterion for URF.

o The head lost during operation can be recovered

through back-flushing periodically. So, back-flushing results in

extending the URF runs.

For More Open Access Journals Please Click on: Juniper Publishers

Fore More Articles Please Visit: Civil Engineering Research Journal

Fore More Articles Please Visit: Civil Engineering Research Journal

Comments

Post a Comment