The Efficiency Evaluation of Applying Poly Ferric Sulfate and Perlite for Filtration- Juniper Publishers

Juniper Publishers- Journal of Civil Engineering

Abstract

The horrible quality of water from sand filters leads

us to study on the basis and sieving for this sort of filtration. In

addition, we assessed surface charges in the style of 4 samples

regarding chemical treatment from two areas before going to water

treatment plant and from output.

Our inspection demonstrated that the combination of perlite and certain

dosage of poly ferric sulfate with the filter surface 60% of surface

charge shows desirable efficiency.

Keywords: Ferric; Perlite; Turbidity; Liquor; UrbanaizationAbbrevations: Al: Aluminum; Fe: Iron; PACI: Poly Aluminum Chloride; DOC: Dissolved Organic Carbon

Introduction

Growing population, improving of living standards,

urbanization, industrial development and agriculture are the main

factors that increased water consumption and waste water production in

the community, consequently giving rise to environmental pollution [1,2].

Filtration is a separation process that consists in

passing a solid-liquid mixture through a porous material (filter) which

retains the solids and allows the liquid to pass through [3,4].

Removing suspended solids by high-rate granular filtration is a complex

process involving a number of phenomena. Attempts to develop theories

that quantitatively predict solids removal performance with sufficient

precision and versatility to be of use in practical filter design have

met with relatively little success. Consequently, filter media selection

is often an empirical process. Pilot investigations are common tools

for assessing the performance of a particular filter design [5-7].

The used process for water treatment depends on the

quality of water resource. Surface water normally has more variable

pollutants compared with underground water, despite the fact this

surface water could do with more complicated treatment process [8,9].

The most surface water in the world has more pollutants and turbidity

compared with standards for potable water. Although, high velocity of

water stream might have more suspended solids, the most of them are in

colloidal size. Hence, coagulation and filtration are good choice for

treatment [10-12].

The first extensive use of perlite was for filtration of raw cane sugar liquor as early as 1876 [13].

Today the primary industrial application of diatomite is as an

industrial filtration medium for liquids ranging from municipal water

supplies to alcoholic beverages. In contrast, substantial commercial

production of perlite did not begin until 1846. In 1963 only 15 percent

of the perlite produced in the United States was used as filter media [14].

Light weight expanded perlite structures are milled

and classified using strictly defined processes to produce perlite

filter aids with specific flow characteristics. The various grades

utilize the jagged inter locking structure to create billions of

micro-scopic channels between the filter aid particles to produce

optimum flow rates and clarification ability for a wide variety of

applications [15].

Perlite filter aids are light weight, inert, impart

no taste or odor to liquids being filtered and are virtually in soluble

in mineral and organic acids at all temperatures, solubility in strong

alkaline solutions vary depending on temperature and contact time [16].

Without using the filter aids the solid particles in liquid will soon

accumulate on filtering surfaces and block them. A perlite filter aid

makes a filtering layer that transfers the actual filtering from the

septum to the whole mass of filter aid. Filtration occurs in the tiny

pores formed by the fine particles of filter aid [17].

This study aims to find effective factors on

efficiency of filtration in order to enhance efficiency of physical and

chemical parameter and most importantly reducing turbidity [18].

This study presents the recent laboratory research

related to the application of engineered nano particles consisting of in

organic phases in water treatment and their classification in the

fields of heavy metal removal, anti microbial activity and organic

compound degradation. The reported results are discussed not only

according to their potential for application in different drinking water

treatment processes but also from a critical consideration of the

possibility to scale-up in technologically viable methods and become

competitive with existing techniques and conventional materials. As one

of the main limitations in the effort to evaluate the efficiency of nano

materials from different authors is the absence of a unified procedure

that enables direct comparison of results, this work suggests an

experimental methodology working with reliable conditions and parameter

ranges of drinking water treatment and generating proper indices for the

validation of performance.

Aluminum (Al) and iron (Fe) salts are two widely used

coagulants. Large flocs are formed in water sub sequent to hydrolysis

of the metal-based coagulants and then settled in a sedimentation tank.

The floc properties (e.g., size, density and strength) determined by

coagulant species, chemical dosage, and solution chemistry significantly

influence coagulation efficiency. Further, the coagulation performance

can greatly affect the membrane process For example, small floc sizes

lead to high cake resistance on membranes. Prior efforts were made to

determine an optimal coagulant dosage to minimize membrane fouling. Lee

et al. found an optimal poly aluminum chloride (PACl) dosage with

respect to fouling minimization, and the dosage depended heavily on the

physical and chemical characteristics of the waste water. Tran et al.

reported that dissolved organic carbon (DOC) in water could be

significantly reduced with a specified dosage of Al to reduce membrane

fouling.

Methods

Due to the fact that changing materials on the basis

of filtration is much expensive, we assumed the part of it as our model.

The evaluated parameters were turbidity, TSS, total solids, the amount

of Ca and Mg. we got our samples from two area first was the water which

goes to water treatment plant and second was in output of water

treatment plant.

The methods considering the experiments divided into

different stages which each of them implies divergent episodes. First

step was done without any coagulation, we carried out our experiments on

filtration soon after sedimentation and we attained the chemical

properties after our experiments on two samples and we call this step A.

Second step was done with using poly ferric sulfate as our best

coagulants, we used poly ferric sulfate with dosage of 8ppm as the

optimum dose, several hours later of jar test, we implemented filtration

experiment on this sample and attained the results on chemical

properties and we named this step B. Next step was done with combination

of using perlite and anthracite, in this step we added perlite with

anthracite on the surface of filtration, we arranged the array of them

respectively from upside to down part, perlite 48cm (ranging of sieving

0.5-2mm), anthracite 45cm (1-3mm), perlite 15cm (4-6mm), perlite 24cm

(5-8). After making adjustment on grading we performed our experiments

and attained the results and we named it C. The last step was done

similar to prior one but with the difference of height of used materials

in filtration, we changed the surface charge and reduced it up to 60%

of our last experiments, after making some alteration on grading and

surface charges we attained our results and we named it D.

Results

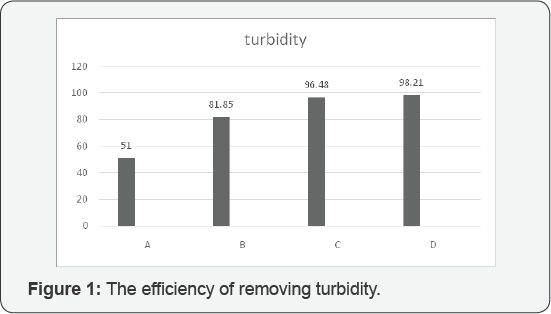

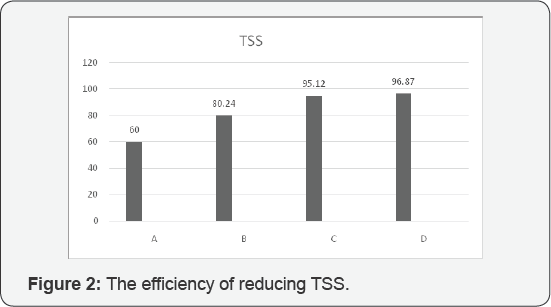

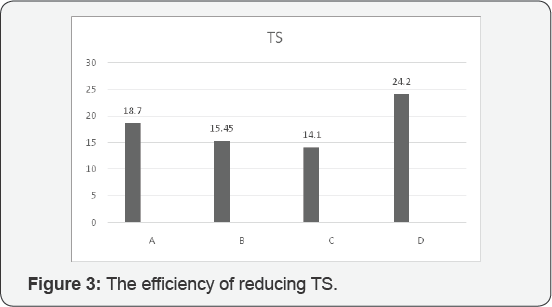

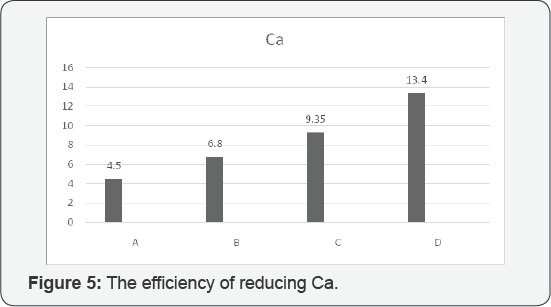

According to our evaluation and analysis of

experiments, these are being claimed that the best efficiency of

turbidity assigned to C and D respectively 96.48% and 98.21%. The best

efficiency for reducing TSS was assigned to D with 96.87 %, moreover,

the best efficiency for reducing total solids was allocated to D with

24.2%, the best efficiency for reducing Ca was assigned to D with 13.4

%. And also fourth stage succeeded to get the best efficiency of

reducing Mg with 26.5 %. (Figure 1-5).

Conclusion

Pursuant to our results in analyzing our samples

considering the parameters TSS, turbidity, total solids, Mg and Ca, it

clearly shows that this method is pretty impeccable if we use it

properly in the case of applying poly ferric sulfate for coagulation, it

gives rise to boost the quality of water as it is depicted in charts as

well as reducing turbidity as well as decreasing the amount of fees for

removing disinfection with considering PH and temperature and another

metals materials in the water. In compared with current methods in

scientific world, this method and results demonstrate the new idea and

method in order to get standard quality according to US EPA.

For More Open Access Journals Please Click on: Juniper Publishers

Fore More Articles Please Visit: Civil Engineering Research Journal

Comments

Post a Comment