Mechanical Properties and Structural Performance of Recycled Aggregate Concrete: An Overview-Juniper Publishers

Juniper Publishers Journal of Civil Engineering

Abstract

Using Recycled Concrete Aggregate (RCA) in concrete

has been the subject of many studies for years. A comprehensive

literature review on mechanical properties of Recycled Aggregate

Concrete (RAC) including splitting tensile strength, modulus of

elasticity, flexural strength, and fracture mechanic is presented.

Furthermore, this paper summarizes previous studies on structural

behavior (shear, flexural, and bond) of RAC.In addition, databases are

created for both mechanical properties and structural performances of

RAC in order to lead to changes or acceptance in design codes and

standards' provisions. Additionally, mechanical properties and

structural strengths of RAC were compared with both the U.S. and

European standards. Results of this study show that existing code

provisions are not conservative for both mechanical properties and

structural strengths of RAC.

Keywords: Mechanical Properties; Structural performance; Recycled Concrete Aggregate

Introduction

Around 25 billion tons of concrete is used each year globally that means over 3.8 tons per person in the world each year [1].

Occupying about 60% to 70% of the volume, aggregate is a main

ingredient of concrete. Nowadays, there is an increasing trend toward

using sustainable concrete and reusing of aggregates from demolished

concrete is one way to achieve this aim. Although using recycled

concrete aggregate (RCA) does not lead to significant reduction of CO2

emission, but it reduces using natural resources (virgin aggregate) as

well as helping to reduce dumping construction and demolition wastes in

landfills. More than 900 million tons of construction and demolition

waste is produced each year only in Europe, the U.S., and Japan [1].

The use of RCA to make a new concrete began in Europe after World War

II. Also the building contractors' society of Japan started research on

RCA after the 1973 oil crisis [2].

Although comprehensive research has been done on fresh and hardened

properties of recycled aggregate concrete (RAC), relatively limited

studies have been performed on structural behavior of RAC. This paper

compiles around 60 published studies (from 1977 to 2015) that studied

mechanical properties (splitting tensile strength, modulus of

elasticity, flexural strength, and fracture mechanic) as well as

structural performance (shear, flexural, and bond) of RAC. The work

presented here summarized only those studies that used RCA as a coarse

aggregate replacement. Given the fact that incorporation of fine RCA is

typically reported to result in inferior fresh and hardened properties,

the present study summarizes the properties of RCA incorporating coarse

RCA [3].

Mechanical Properties

The following section compares splitting tensile

strength and flexural strength as well as modulus of elasticity and

fracture energy of RAC with the ACI 318, CEB-FIP, Eurocode 2 and JSCE

provisions [4,7].

Splitting tensile strength

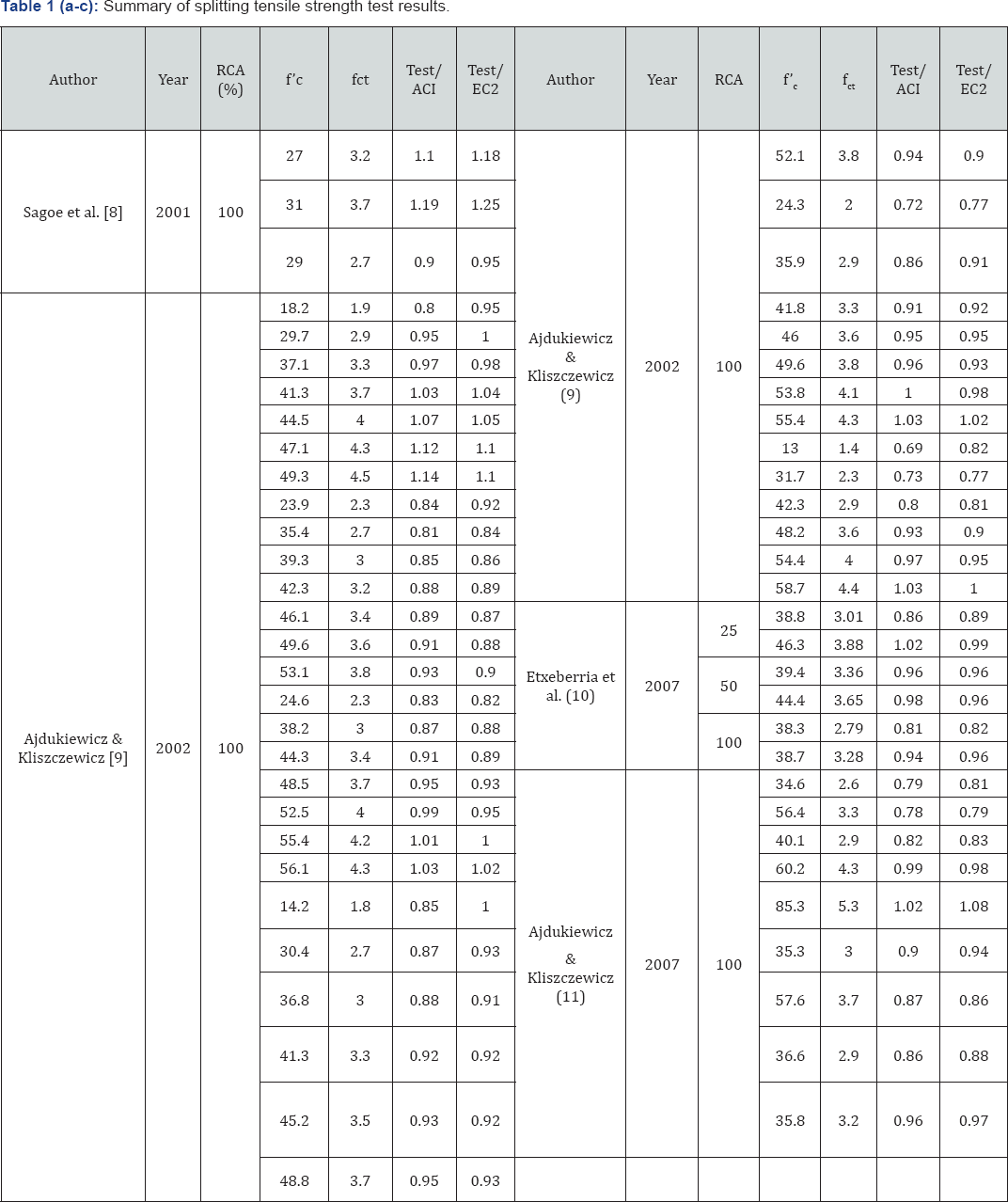

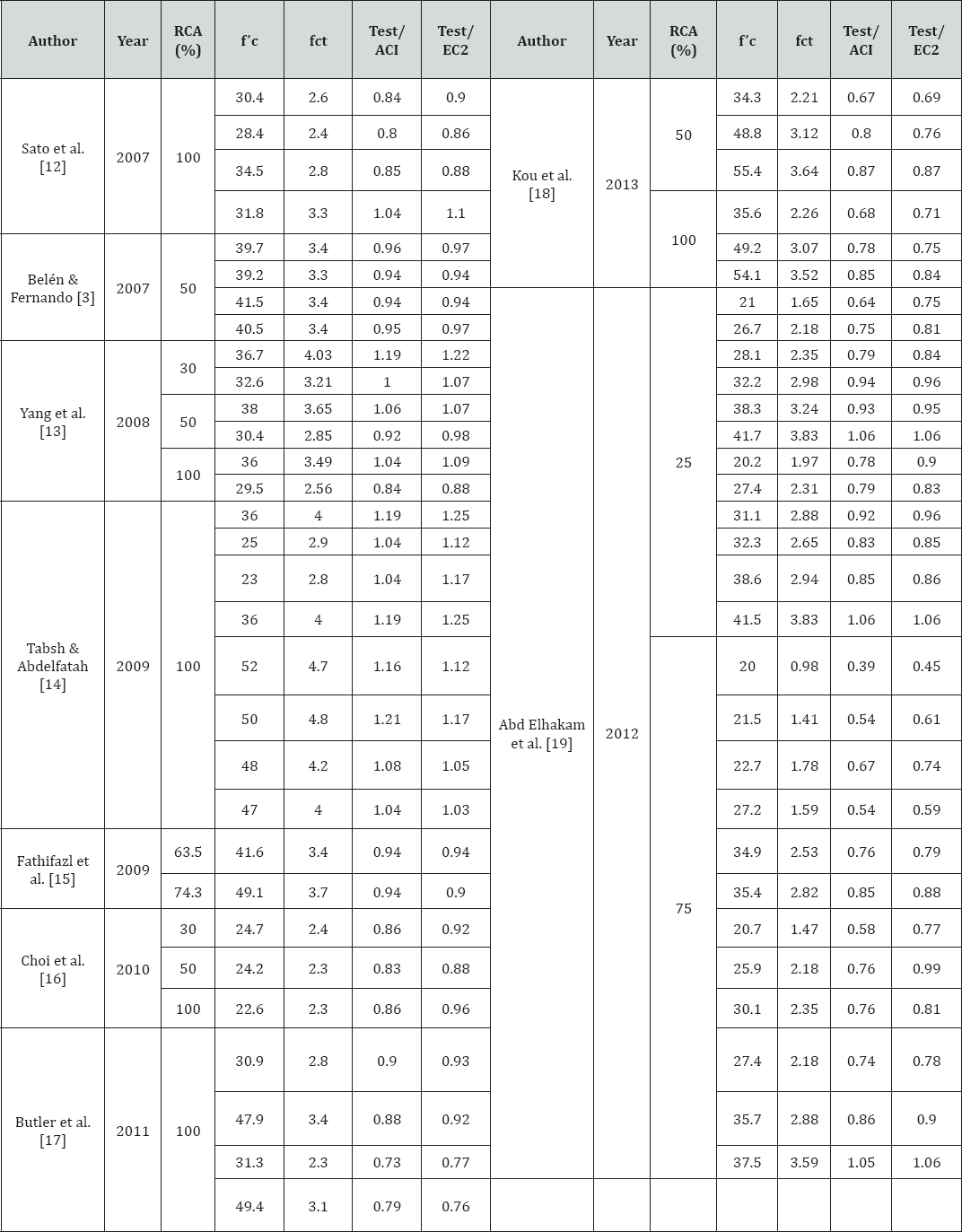

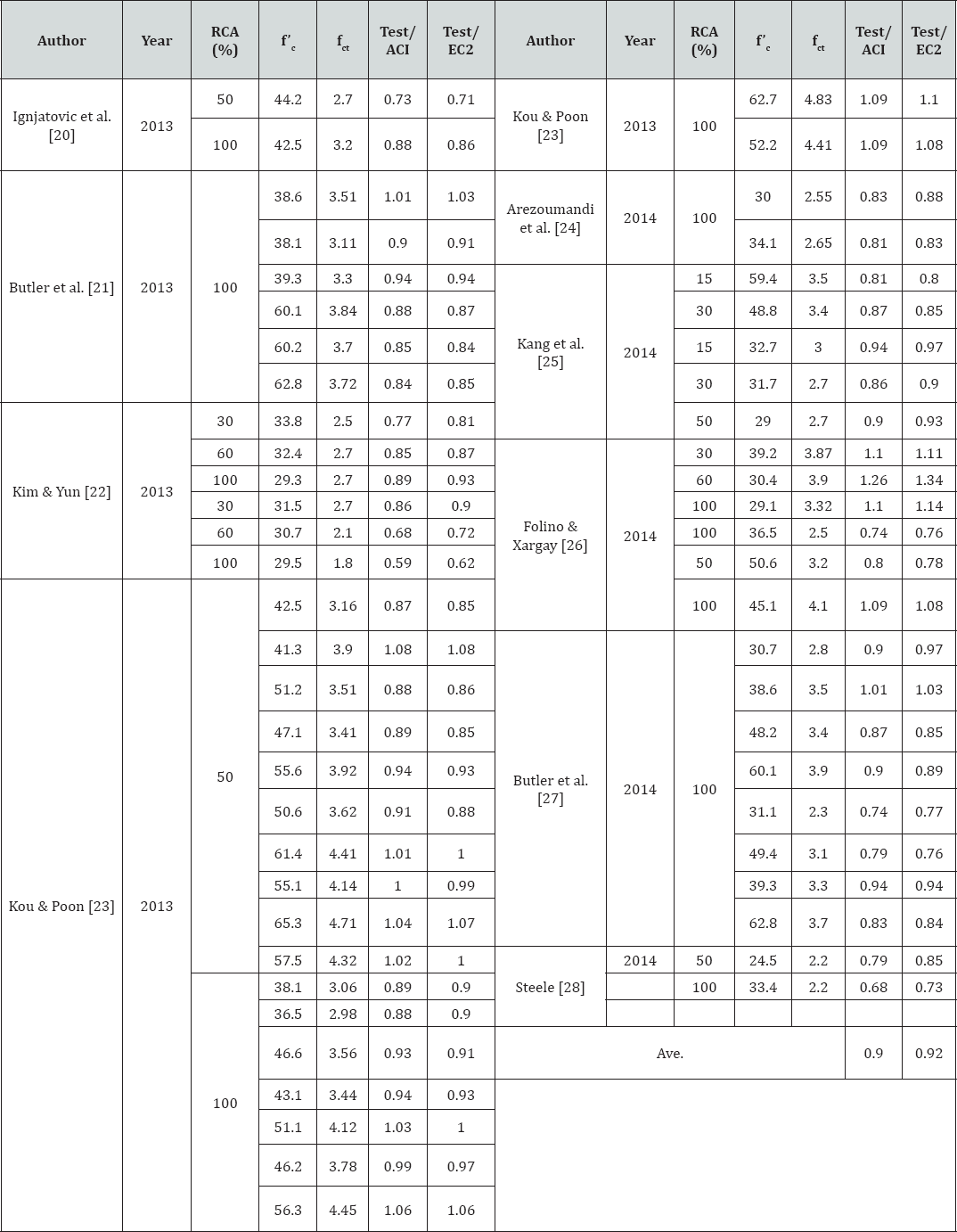

Table 1(a,c) summarizes the compressive strength (f&c) splitting tensile strength(fct) and ratio of the experimental-to- code values for splitting tensile strength based on the ACI 318 [5] and Eurocode 2 [7] provisions for previous studies [8-28]. The average values of experimental-to-code ratio are 0.90 and 0.92 for the ACI 318 [5] and Eurocode 2 [7]

provisions, respectively. Both provisions are conservative for about

22% of the data points. In other words, the investigated codes

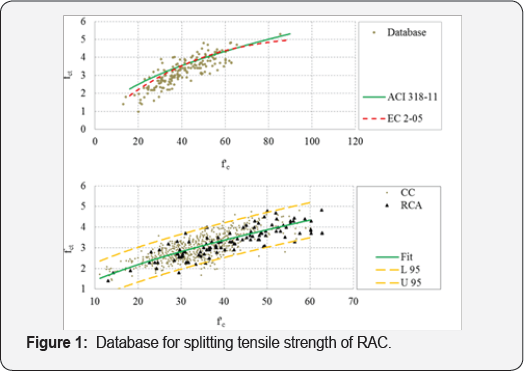

overestimate the splitting tensile strength for RAC (Figure 1)

based on measured compressive strength values. Furthermore, Regression

analysis was conducted to draw the best fit and 95% confidence intervals

for the investigated data points. The lower and upper 95% confidence

intervals (L95 and U95) are established. Results of the statistical data

analysis reveal the fact that even in the case of the mixtures made

with 100% RCA replacement (RAC-100), test results fall within a 95%

confidence interval of a nonlinear regression curve fit of the

conventional concrete (CC) database (Figure 1).

Flexural strength

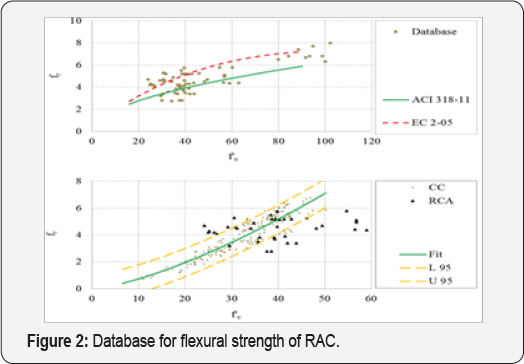

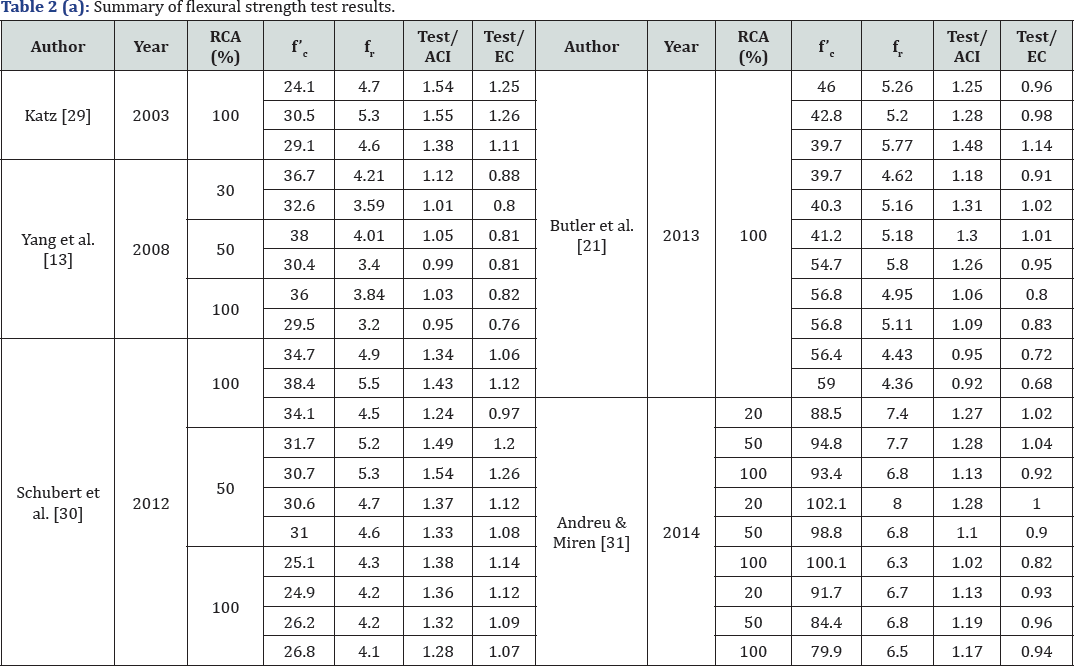

Figure 2 presents the flexural strength database of RAC mixtures compared to the provisions of both ACI 318 [5] and Eurocode 2 [6].

Based on the observed trends, it may be concluded that both provisions

over predict flexural strength of RAC. However, the ACI 318 [4]

is unconservative for 24% of the data points compared to

overestimations observed for about 65% of the data points in the case of

the EC 2 [6]. Table 2 (a),Table 2 (b))

summarizes the compressive strength, fc, flexural strength, fr, and the

experimental-to-code ratios for flexural strength based on the ACI 318 [4] and EC 2 [6]

provisions for previous studies from 2003 to 2014. The average values

of the experimental-to- code ratios are 1.15 for the ACI 318 [4] and 0.92 for the EC 2 [6]

provision. This reveals the fact that the ACI 318 underestimates the

flexural strength of RAC by 15%, proposing ACI 318 as a reliable source

for predicting the flexural strength of the RCA. Contrary to the ACI

318, the EC2 seems to overestimate the average flexural strength by

about 8%. In addition, regression analysis of the CC data indicates that

part of the RAC-100 test results don't fall within a 95% confidence

interval of a nonlinear regression curve fit of the CC database. This

result indicates that the RAC-100 flexural strength is lower than the CC

for mixes with compressive strength around 35MPa and higher.

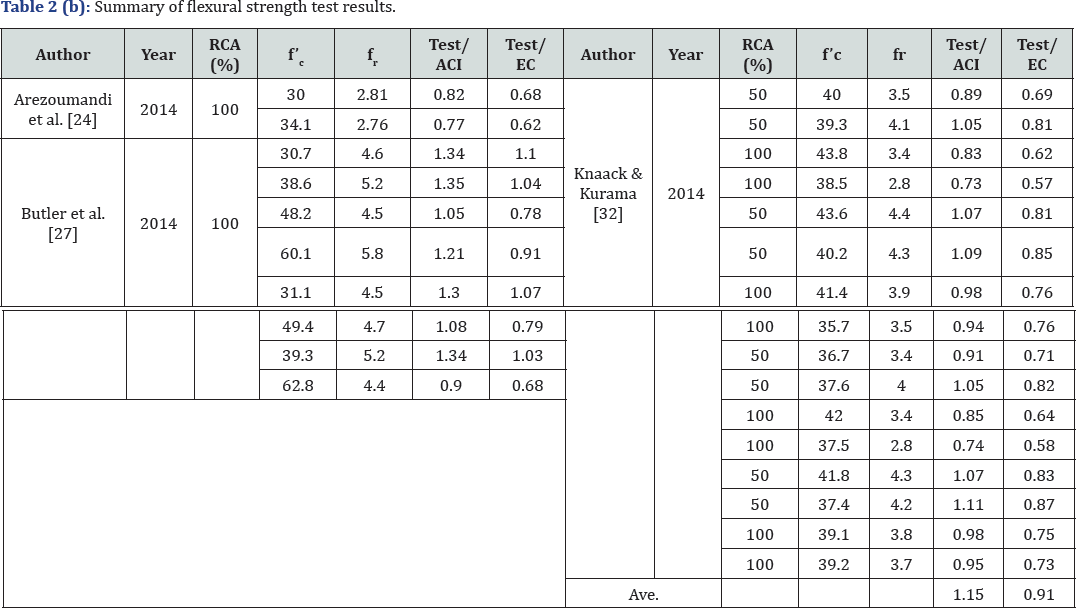

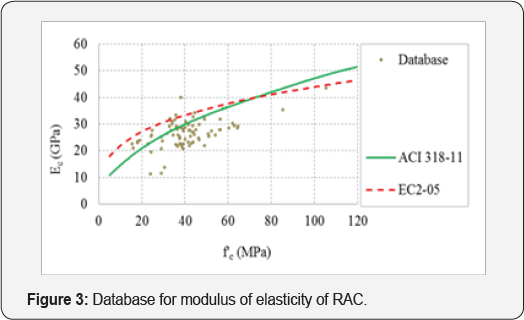

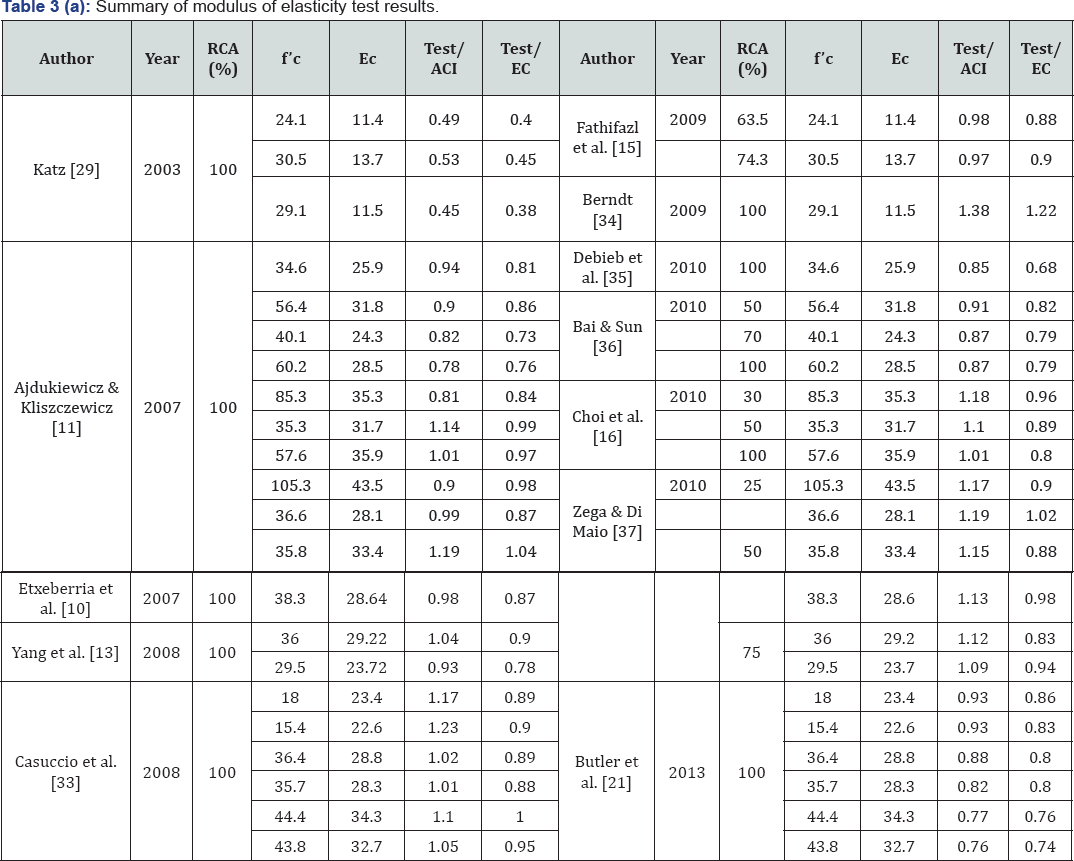

Modulus of elasticity

Table 3 (a,b)

presents the test results for modulus of elasticity from literature on

RAC with replacement level from 25% to 100%. Comparison of test results

with the ACI 318 [4] and EC 2[6] provisions showed only 34% and 5% of results is higher than the codes predictions, respectively (Figure 3).

Almost all the previous studies reported lower modulus of elasticity

for RAC compared to CC and it may be attributed to the lower stiffness

and rigidity of the RCA particles which in turn decrease the rigidity

and modulus of elasticity of the RAC [8].

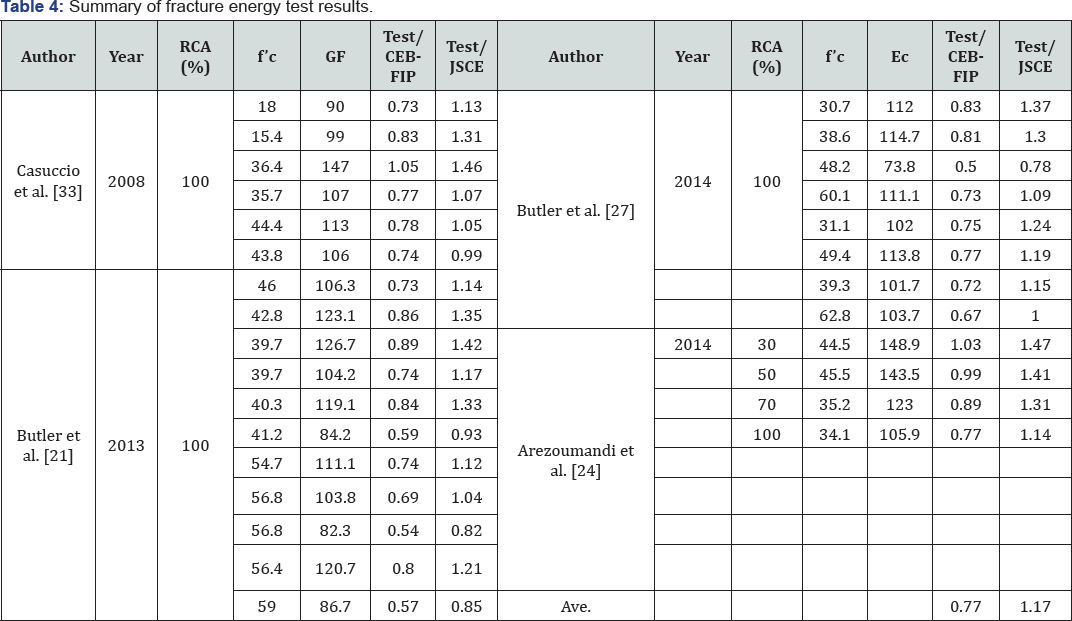

Fracture energy

Limited literature is available in the case of the fracture energy of RAC. Results presented in [21,24,27,33] suggest decrease in fracture energy as a function of increases in RCA replacement ratio. Table 4 shows that the CEB-FIP [5] code provision is conservative only for 7% of the investigated data points The Japan's code [7] underestimates the fracture energy for 17% of the experimental results (Table 4).

Likewise splitting tensile strength, statistical analysis of the data

shows that the RAC-100 test results fall within a 95% confidence

interval of a nonlinear regression curve fit of the CC database. That

means the RAC-100 fracture energy is similar to the CC (Figure 4).

Structural Performance

The following sections compare structural test

results of RAC including bond, flexural, and shear strength with both

codes provisions and CC databases.

Bond Strength

Three most common methods to measure bond strength

between reinforcing steel and concrete are pull-out, beam-end, and

splice specimens. Although pull-out test method is the most commonly

used due to the ease of sample fabrication, but this method has the

least realistic bond strength measurements. The reason is the bar at

pull-out specimen is loaded in tension and the surrounding concrete is

in compression, but in most practical applications, both the bar and

surrounding concrete experience tensile stresses. For beam-end and

splice specimens test methods, both the bar and surrounding concrete are

in tension and provide a more realistic response [40]. The following section discusses the results of each test method separately.

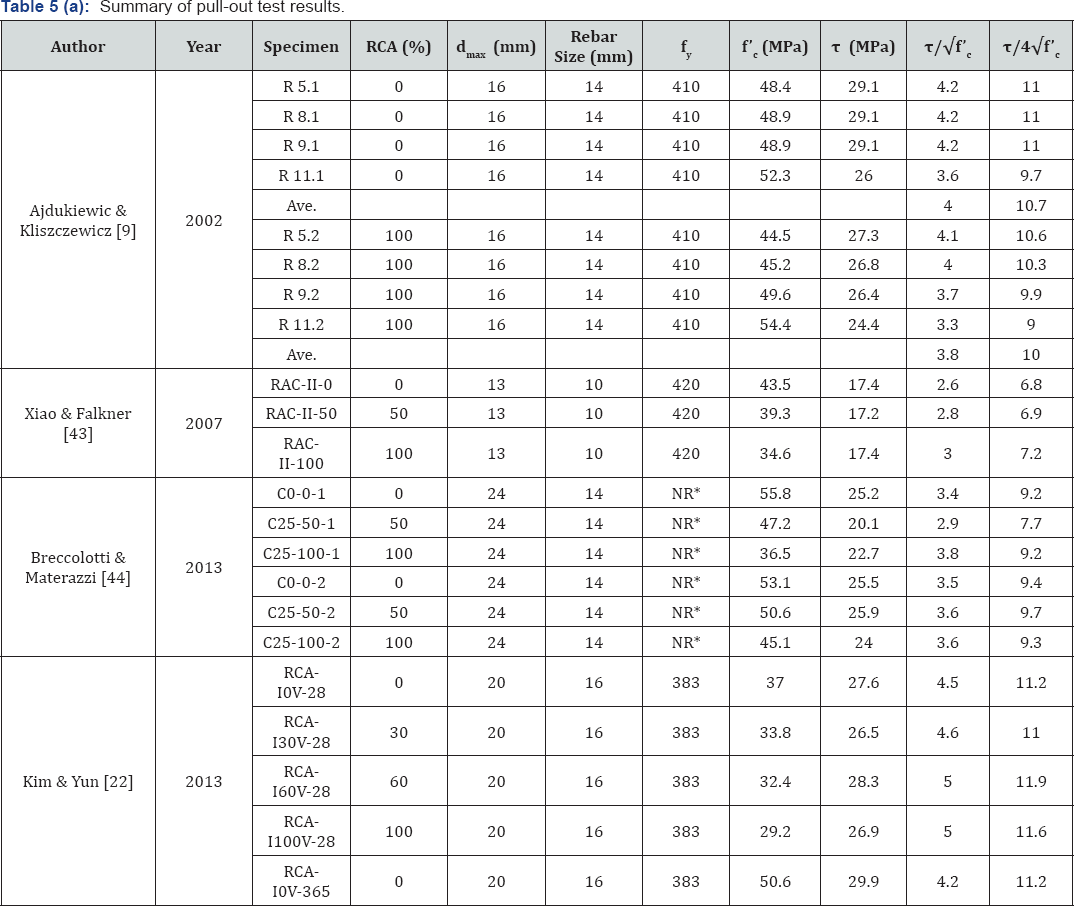

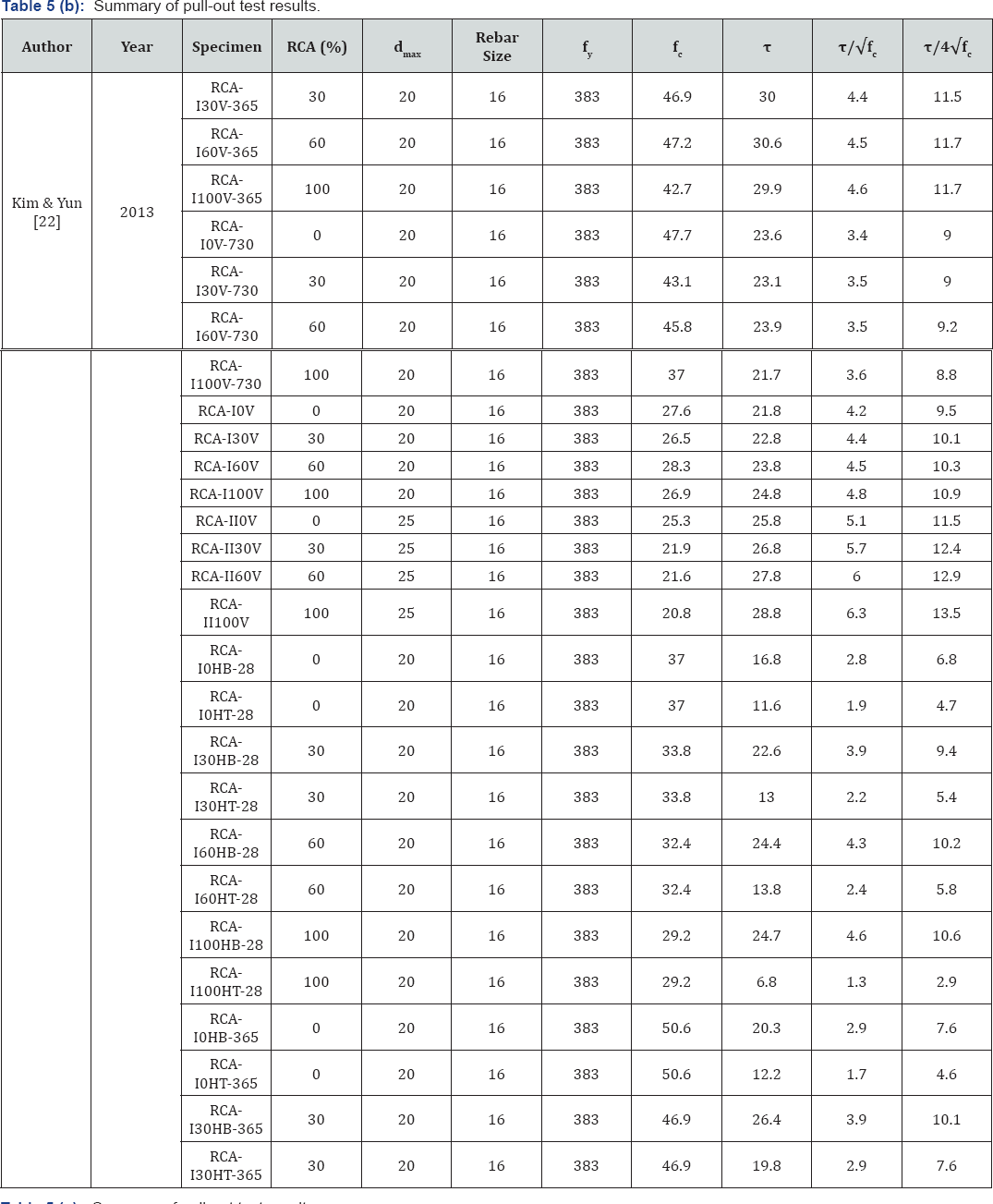

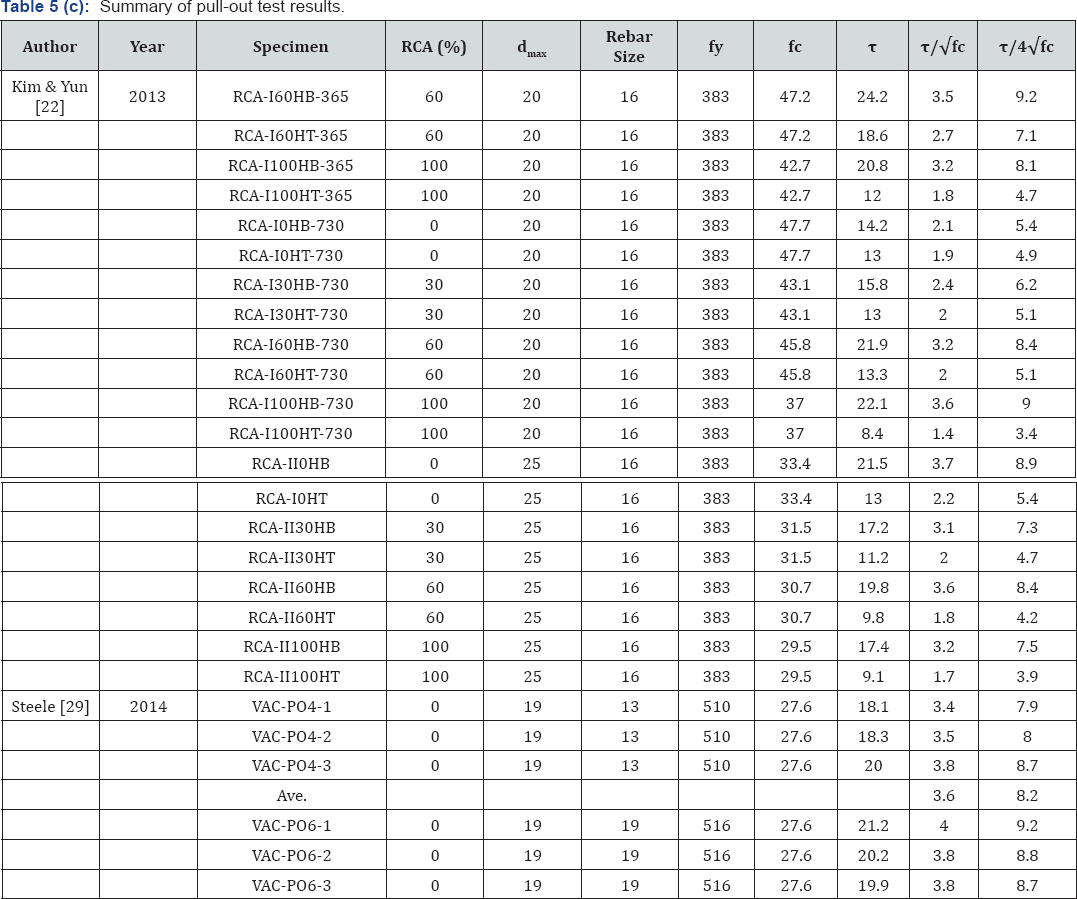

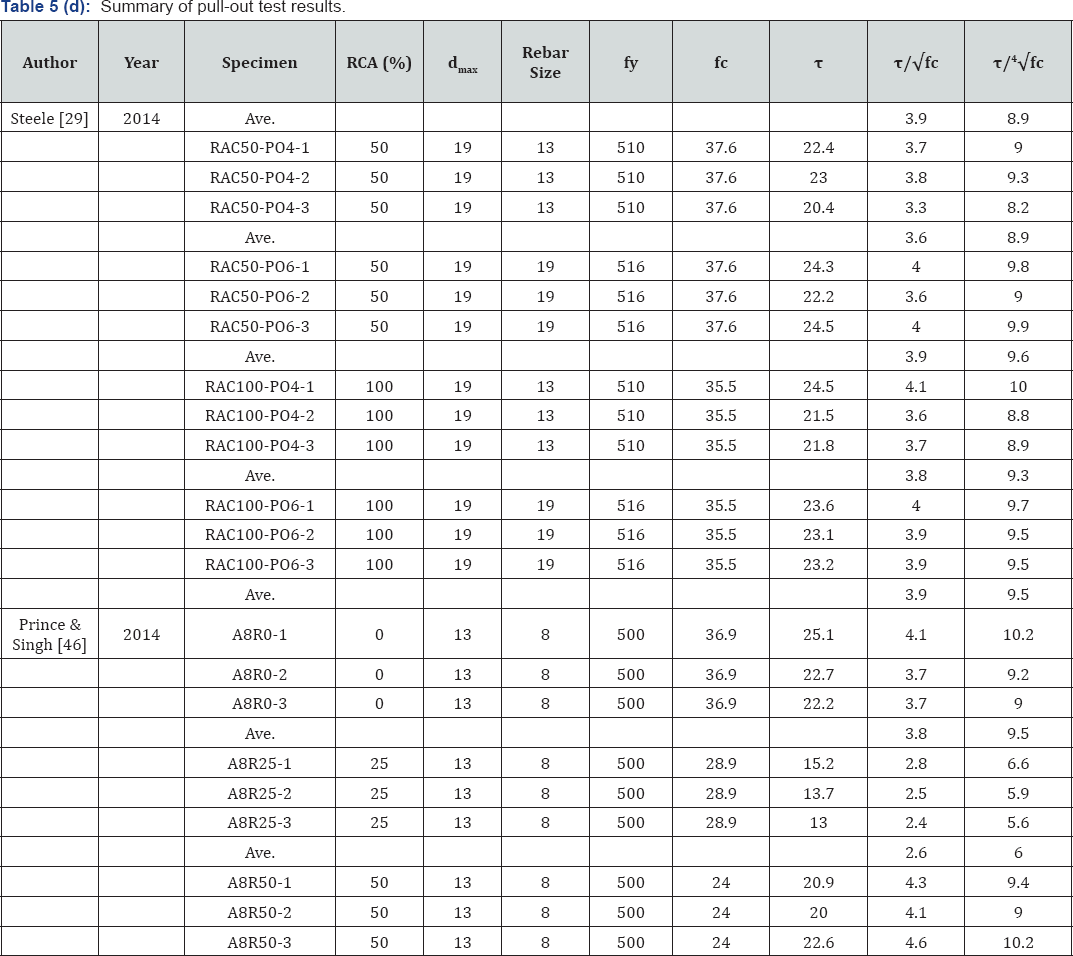

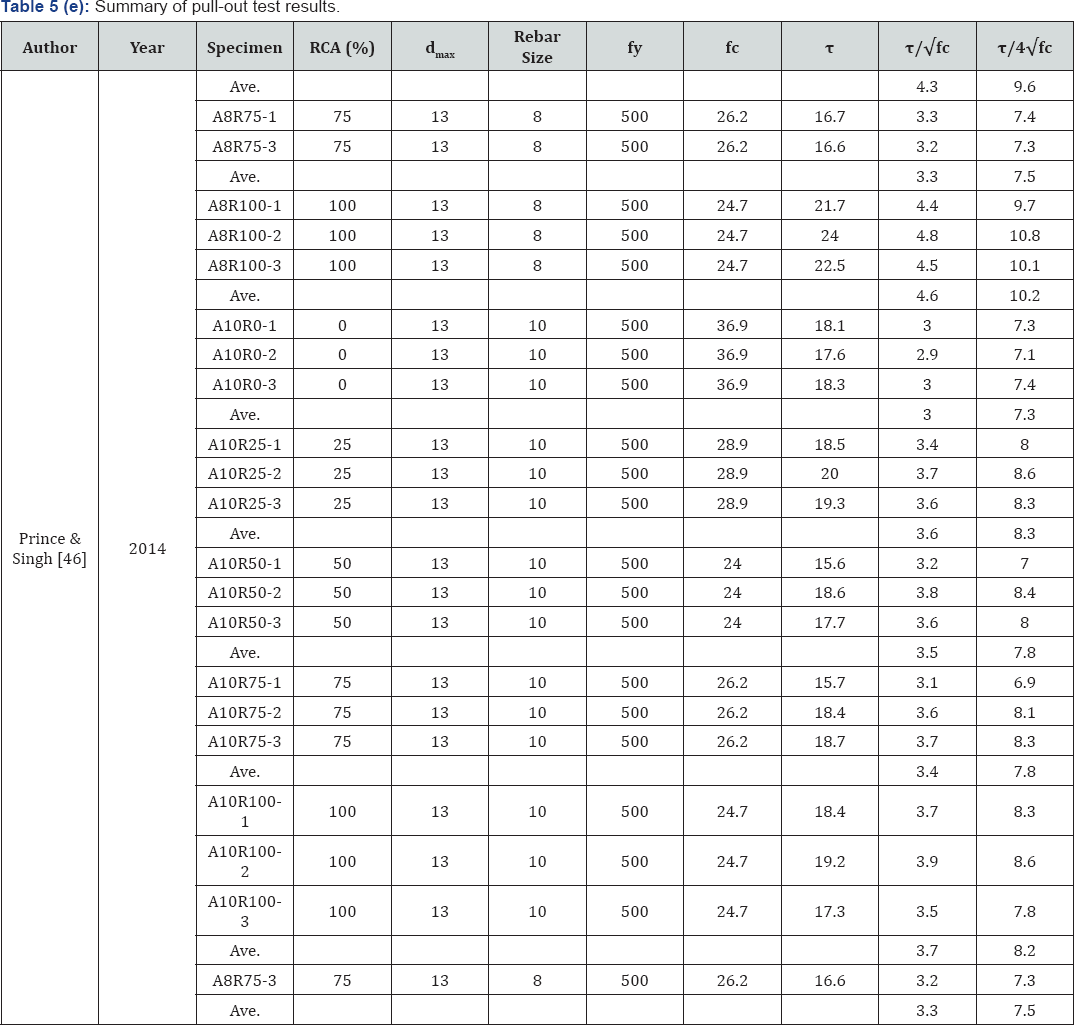

Pull-out

Table 5(a-e) summarizes the results of pull-out tests from previous studies including RCA replacement level, compressive strength, f'c and maximum aggregate size (dmax), rebar size, yielding strength of reinforcing steel (f) , average bond stress, τ, and normalized bond strength,  . The bond [4,7,14-16], but the ACI 408 [13]

recommends the fourth root of strength provision is a function of the

inverse square root of the the compressive strength of concrete instead

of the square root. compressive strength of concrete for most of design

standards For this reason Table 5(a-e] presents normalized bond strength of previous studies for both methods.

. The bond [4,7,14-16], but the ACI 408 [13]

recommends the fourth root of strength provision is a function of the

inverse square root of the the compressive strength of concrete instead

of the square root. compressive strength of concrete for most of design

standards For this reason Table 5(a-e] presents normalized bond strength of previous studies for both methods.

. The bond [4,7,14-16], but the ACI 408 [13]

recommends the fourth root of strength provision is a function of the

inverse square root of the the compressive strength of concrete instead

of the square root. compressive strength of concrete for most of design

standards For this reason Table 5(a-e] presents normalized bond strength of previous studies for both methods.

. The bond [4,7,14-16], but the ACI 408 [13]

recommends the fourth root of strength provision is a function of the

inverse square root of the the compressive strength of concrete instead

of the square root. compressive strength of concrete for most of design

standards For this reason Table 5(a-e] presents normalized bond strength of previous studies for both methods.

Mukai & Kikuchi [41]

used both 15% and 30 % RCA replacement in their specimens and reported

no reduction in bond between reinforcing steel and RAC. Ajdukiewicz

& Kliszczewicz [11] replaced 100% RCA from seven years old structures for pull-out specimens based on RILEM 7-II-128 [42]. Their results showed that the RAC specimens possess 7% lower bond strength compared to the Xiao & Falkner [43]

tested 36 pull-out specimens with 0, 50%, and 100% RCA replacement and

reported similar load-slip curve for RAC specimens. However, 4% and 12%

increase on bond strength of RAC was reported for the 50% and 100%

replacements, respectively compared to the Breccolotti & Materazzi [44]

used pull-out specimens with 0, 50%, and 100% RCA replacement and

observed no significant difference between bond strength of the RAC and

CC specimens.

Kim & Yun [22]

used RCA with the replacement ratios of 30%, 60%, and 100% to make 144

direct pull-out tests. Authors reported that the RAC specimens with the

smaller aggregate size had a greater bond strength compared to the

specimen with the larger aggregate size, while the CC specimen showed

similar bond strength for both aggregate sizes. Furthermore, authors

reported that the current ACI 318 [5] and CSA [45] codes provisions can be applied to RAC specimens. Steele [28]

results showed that replacing both 50% and 100% RCA slightly improved

the bond strength of reinforcing steel and RAC compared to the CC

specimens. Prince and Singh [46]

tested 30 pull-out specimens specimens. However, the bond strengths for

10mm diameter with 0, 25%, 50%, 75%, and 100 % RCA replacement ratios

and deformed bars in the RAC were higher than the CC specimens. reported

identical load-slip relationships for the RAC and CC

Splice Beam

Table 6 presents dimensions and mechanical properties of materials used to test splice beams. The only difference is that Table 6 includes reinforcing steel stress at failure, fs, instead of average bond stress based on ACI 408 [40] recommendation. Steele [28]

tested full scale beams with cross section of 300x460mm for both 50%

and 100% RCA replacement levels and reported that the bond strength

decreased around 10% for 50% and 20% for 100% RCA replacement.

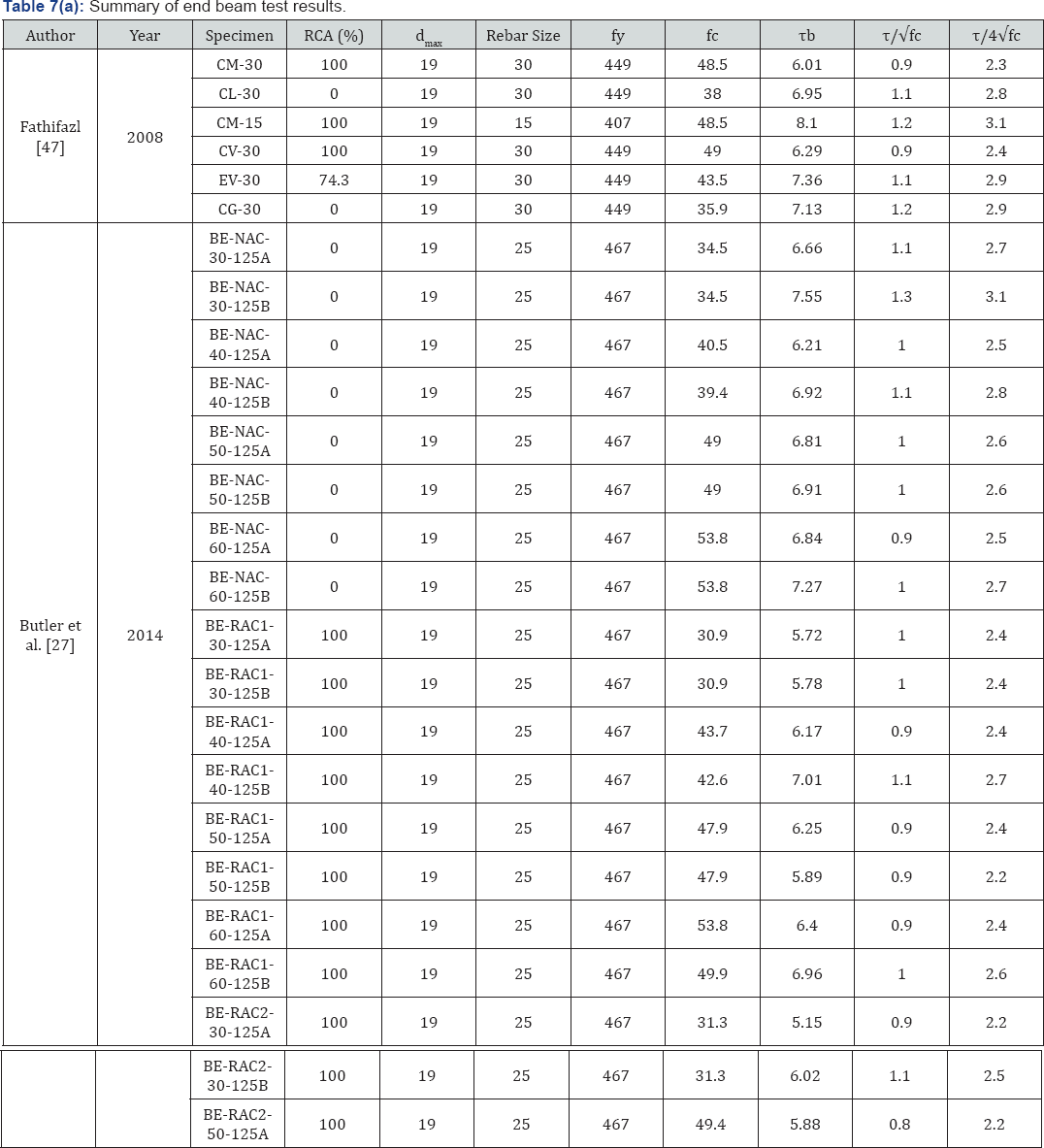

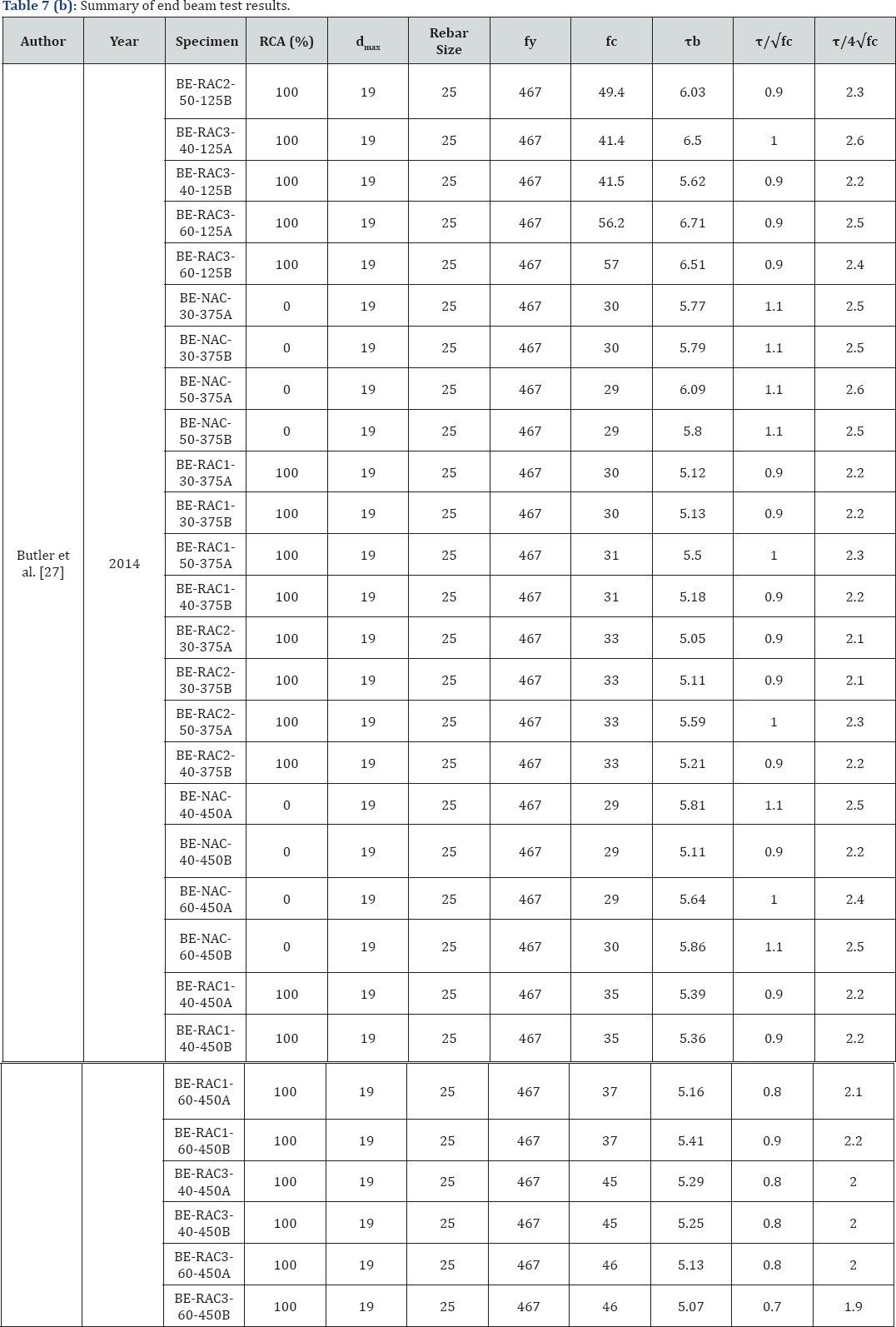

End beam

Fathifazl et al. [47]

used both conventional method (replaced 100% RCA) as well as the

equivalent mortar volume (EMV) method for proportioning RAC. They

reported 24% lower bond strength for the conventional method, while the

EMV method bond strength was comparable (only 6% reduction) with the CC

specimens. Butler et al. [17]

tested 48 beam-end specimens with 100% RCA replacement from different

resources, including regional sidewalk, curb, and gutter infrastructure,

apron and terminal structures from Pearson International Airport in

Toronto, Canada, and a concrete ready-mix plant. Their results showed 3%

to 20% reduction in bond strength between reinforcing steel and the RAC

compared to the CC beams. A summary of details for end beam tests can

be found in Table 7 (a,b).

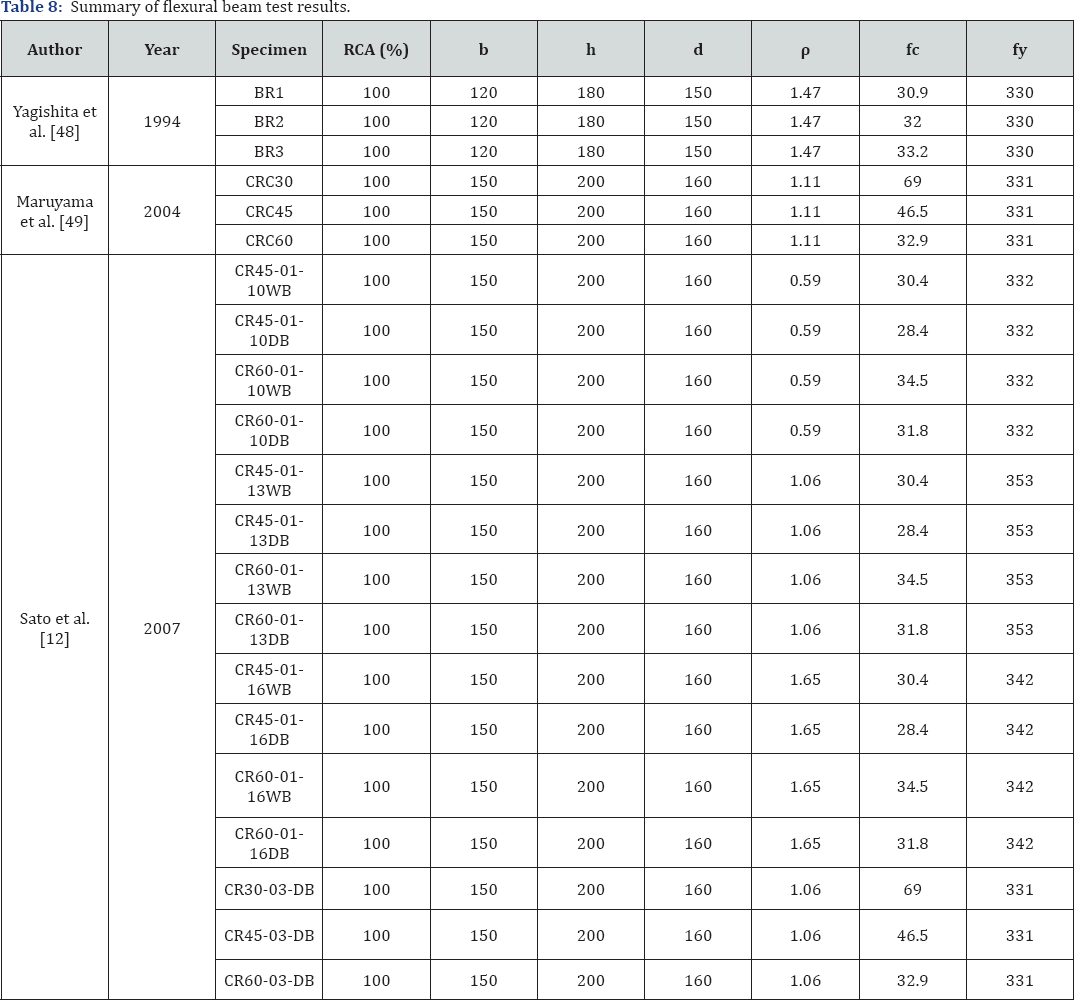

Flexural Strength

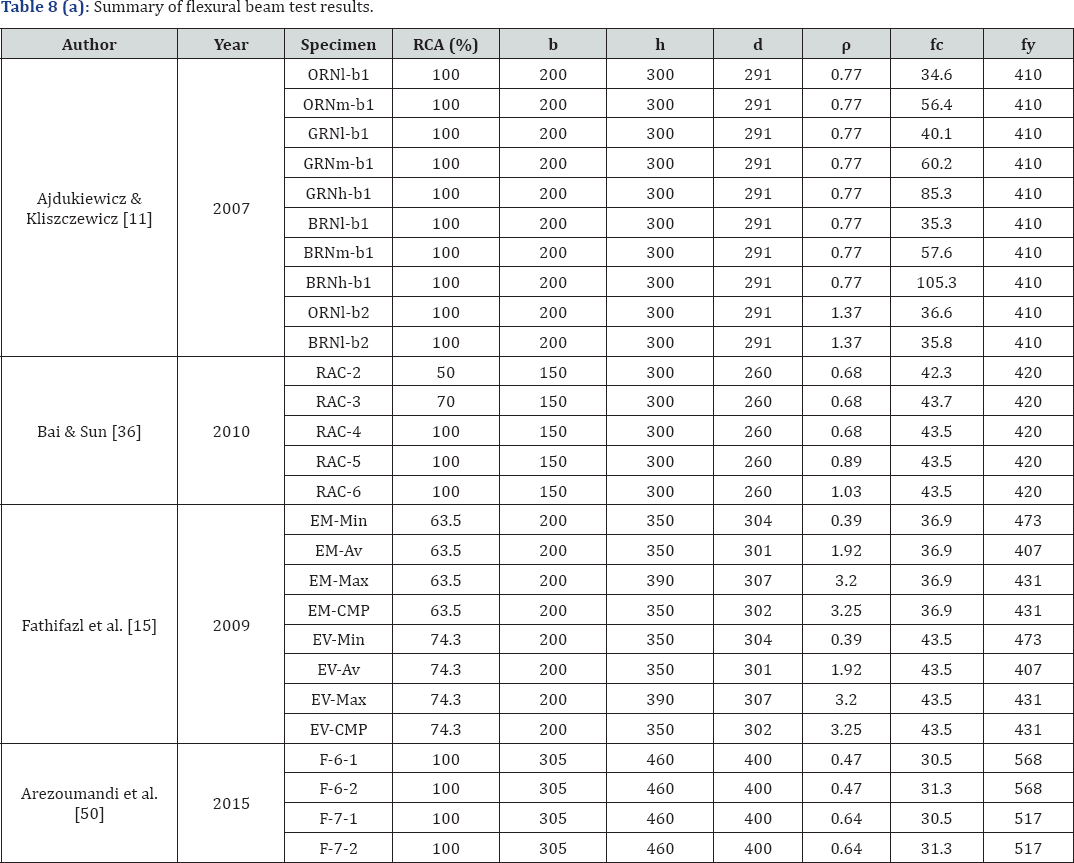

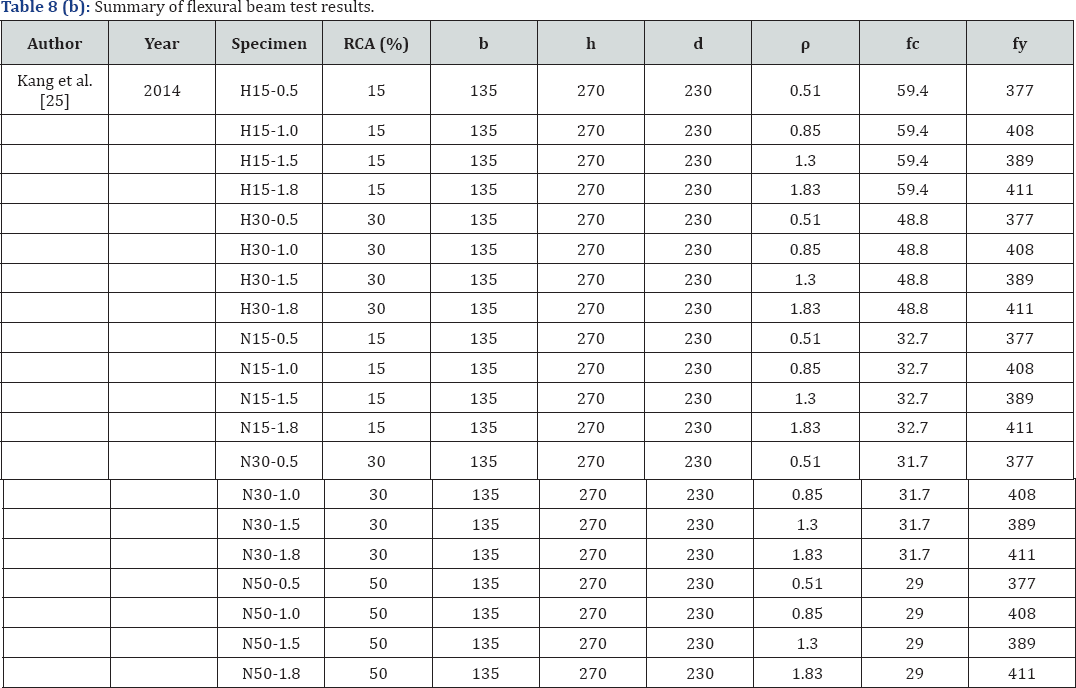

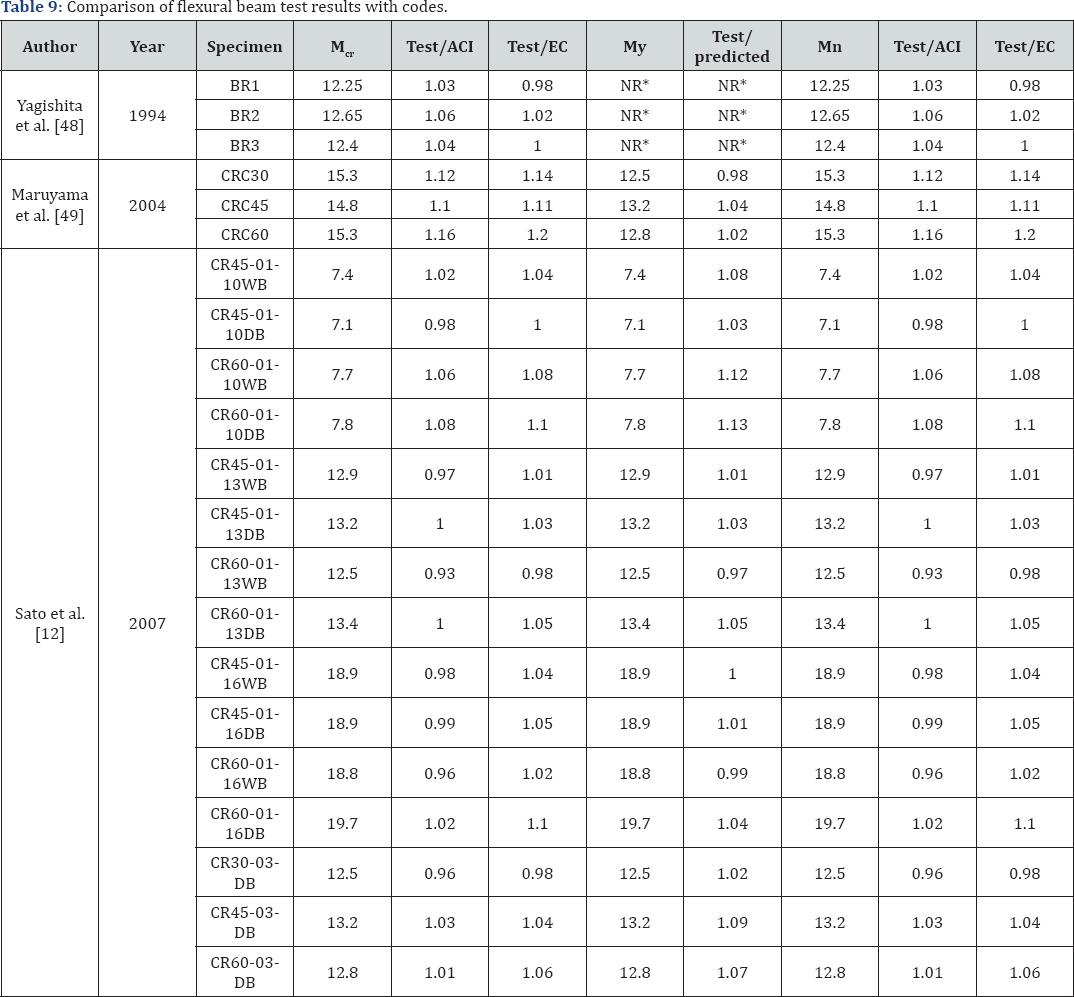

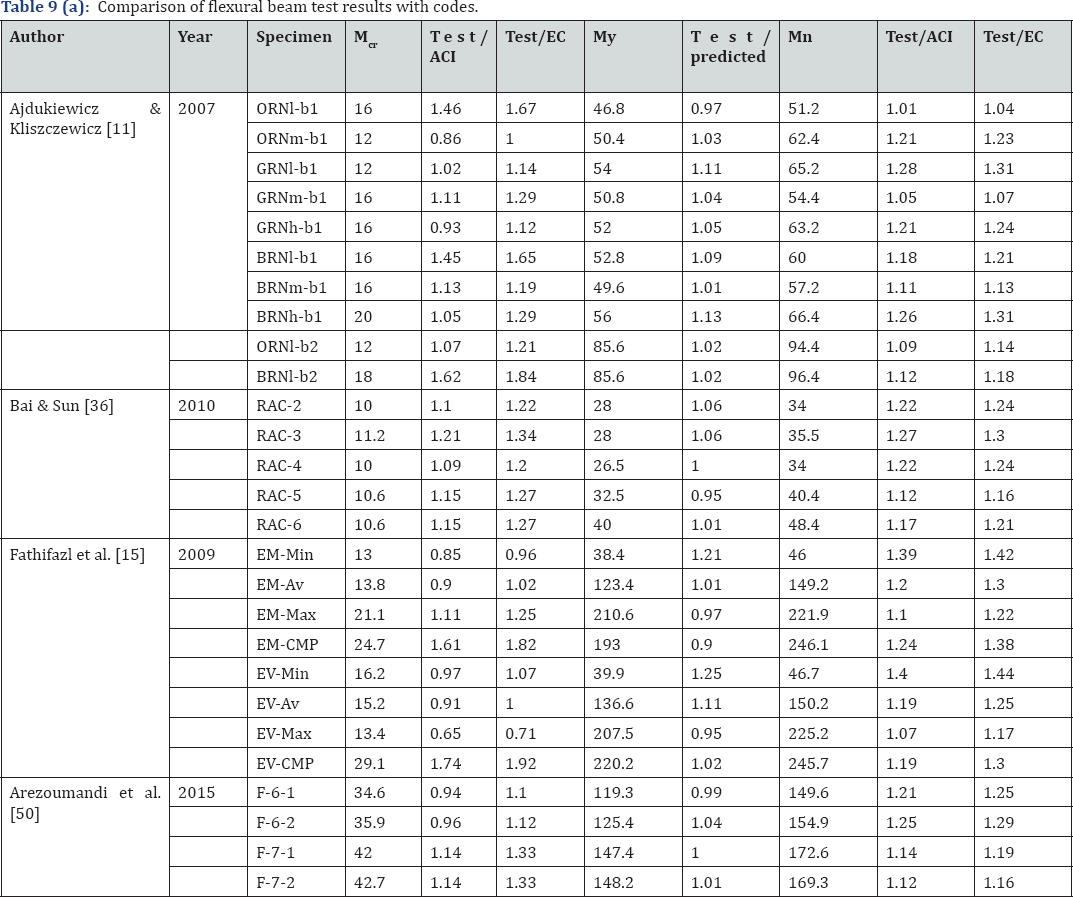

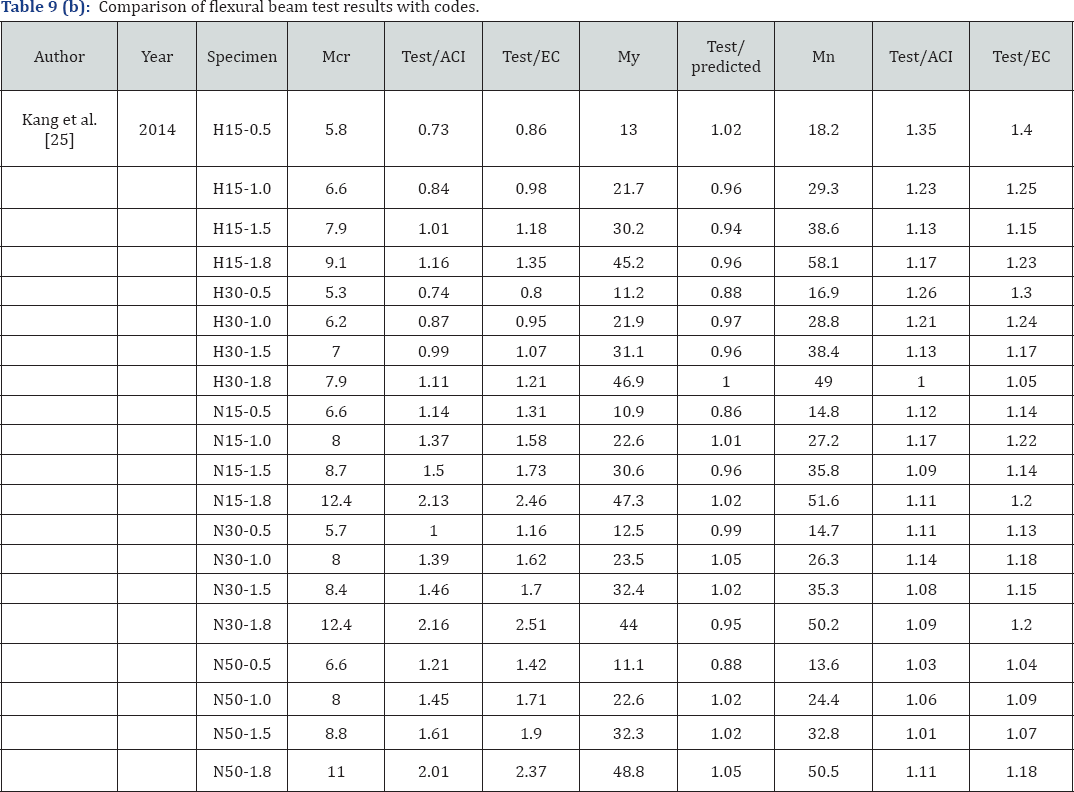

Table 8 (a,b) presents details of flexural test specimens from previous research. Table 9 (a,b) compares cracking moment (Mcr) , yielding moment(My) , and ultimate moment(Mcr) , of the RAC beams with both the ACI 318 [5] and EC 2 [7] provisions. Mukai & Kikuchi [41]

tested beams measuring 150x150mm in cross section and 1.8-m in length

with both 15% and 30 % RCA replacement ratios and reported no

significant difference in ultimate moment. However, authors reported

lower cracking moment for RAC beams. Yagashita et al. [48]

used low grade, medium grade, and high grade types of recycled

aggregate with 100% replacement for determining the flexural strength of

reinforced concrete beams. Their results showed using high grade RCA

slightly decrease (around 10%) the flexural capacity of RAC beams.

Ajdukiewicz and Kliszczewicz [11]

used partial or full recycle aggregate. All the beams were fabricated

with rectangular sectons measuring 200x300mm and 2600mm in length with

two longitudinal reinforcement ratios of 0.90% and 1.60%.

They reported that the RAC beams had slightly (3.5%

in average) lower moment capacity and higher deflection compared with

the CC beams. Sato et al. [12]

tested 37 beams with three different longitudinal reinforcement ratios

of 0.59%, 1.06%, and 1.65%. They used 100% recycled aggregate for their

mix designs. Results of their study showed that the RAC beams had larger

deflection compared to the CC beams. In terms of crack spacing no

significant difference observed between the RAC and CC beams. However,

the RAC beams had wider crack openings compared to the CC ones. They

also reported almost the same ultimate moment for the RAC and CC beams.

Maruyama et al. [49]

tested beams with 1% longitudinal reinforcement ratio and reported that

the cracks propagated on the RAC beams were wider and spaced closer

compared to those of the CC beams. The RAC beams had larger deflection,

but authors reported no significant difference between the flexural

capacity of the RAC and CC beams. Fathifazl et al. [15]

incorporated the EMV method for their mix designs. They used both 64%

and 74% RCA as a partial replacement of the coarse aggregate for their

RAC mixtures. Their beams were cast with three different longitudinal

reinforcement ratios ranging between 0.49% and 3.31%. Authors reported

comparable and even superior flexural behavior for RAC beams at both

service and ultimate states. They concluded that the flexural strength

provisions of the current codes can be used for RAC beams. Bai & Sun

[36]

used 8-10 years old RCA with different replacement levels of 50%, 70%,

and 100%. They observed similar crack pattern, but deflection and crack

width increased with the increment of RCA replacement level. They also

concluded that RCA replacement level doesn't significantly affect the

cracking ultimate moment of beams. Ignjatovic et al. [20]

studied nine full scale beams with 0, 50%, and 100% recycled coarse

aggregate and 0.28%, 1.46%, and 2.54% longitudinal reinforcement ratio.

They reported no noticeable difference between load-deflection behavior,

service load deflection, and ultimate flexural strength of RAC and CC

beams. But they observed that the beams with higher range of recycled

aggregate showed higher level of concrete destruction at failure.

Kang et al. [25]

used beams with longitudinal reinforcement ratio ranged between 0.5%

and 1.8% with RCA replacement level up to 50% for both normal and high

strength concrete. They observed greater number of cracks and lower

cracking moment for RAC beams. They also reported no significant

decrease in flexural capacity up to 30% RCA replacement level. Knaack

& Kurama [32]

tested 150x230mm cross section and 2000mm long beams. They used RCA

from late 1920s foundation and with both 50% and 100% replacement level.

They reported higher deflection for the RAC beams, but they concluded

that the existing analytical models and code provisions can be used for

the RAC beams. Arezoumandi et al. [50]

replaced 100% RCA in full scale beams (cross section 300x450mm and

3050mm long) and reported similar crack pattern and flexural capacity,

but lower cracking moment for the RAC beams.

As it can be seen from Table 9 (a,b), in terms of ultimate moment, when 100% RCA used as a coarse aggregate, the ACI 318 [5]and EC 2 [7]

provisions are conservative for 82% and 92% of beams, while only 83% of

the RAC beams showed yielding moment higher than the predicted values.

Furthermore, 53% of the RAC beams showed cracking moment less than the

ACI 318 [5] provision; however, it was 39% when it compared to the EC 2 [7] provision. The ACI 318 [5] and EC 2 [7]

ultimate moment provisions are conservative for the beams used less

than 30% RCA as a coarse aggregate, but in terms of cracking and

yielding moment 30% and 60% of beams showed values less than code

predictions, respectively.

Figure 4

presents the normalized flexural strength versus normalized

longitudinal reinforcement ratio for the RAC beams as well as the wealth

of flexural test data available in the literature for CC [51]. Figure 4

seems to indicate that the RAC and CC test results fall within the

central portion of the data. Furthermore, statistical analysis

(regression analysis) of the data indicates that the RAC and CC test

results fall within a 95% confidence interval of a nonlinear regression

curve fit of the database. This result indicates that the RAC flexural

test values are very consistent with the wealth of flexural test data

available in the literature.

Shear Strength

Mukai & Kikuchi [41]

replaced both 15% and 30 % RCA instead of virgin aggregate and reported

slightly inferior shear strength for the RAC compared with the CC

beams. Han et al. [52]

tested beams with different shear span to depth (a/d=1.5 to 4.0) and

both washed and unwashed RCA and observed no significant difference in

failure mode and shear capacity between the RAC and CC beams; however,

the ACI 318 [5] shear provision was unconservative for beams with a/d greater than 3.0. Yagashita et al. [48]

used low, medium, and high grade RCA with 100% replacement level. They

reported 8% lower shear stress at failure for the RAC beams (with high

grade RCA) compared to the CC. Sogo et al. [53]

used RCA (10 to 40-year-old concrete foundation) for casting the beams

and reported 20% lower shear strength for the RAC beams compared to the

CC beams. Gonza'lez-Fonteboa et al. [54]

tested beams with 50% RCA replacement and observed no significant

difference on shear capacity between the RAC and CC beams. Etxeberria

& Va'zquez [55]

used different percentages of RCA (25%, 50%, and 100%) for casting

specimens and concluded that a substitution of less than 25% RCA,

scarcely affects the shear capacity of RC beams. Ji et al. [56]

tested beams with a cross section of 170x270mm and a shear

span-to-depth of 2 and 100% RCA replacement. Results of their study

showed that existing codes can be used to predict shear strength of the

RAC beams. Choi et al. [16]

tested beams with different span-to-depth ratios (1.50, 2.50 and 3.25)

and different RCA replacement ratios (30%, 50%, and 100%). They reported

the lower shear strength for the RAC beams. Fathifazl et al. [57]

used the EMV method with both 63.5% and74.3% recycled aggregate

replacement as a coarse aggregate for their mix designs. They tested

beams with four different shear span- to-depth ratios ranging between

1.5 and 4. They reported superior shear strength for the RAC beams. They

also concluded that current code provisions for shear conservatively

predicted the capacities of the RAC beams. Schubert et al. [30]

tested slabs with 100% RCA replacement and concluded that existing

codes provision can be used to calculate shear strength of the RAC

slabs. Xiao et al. [58]

tested push-off specimens with different percentages of recycled coarse

aggregate replacement. They observed similar shear stress-slip curves

and crack propagation path between the RAC and CC specimens. They also

reported that more than 30% RCA replacement decrease the ultimate shear

capacity. Arezoumandi et al. [59]

replaced 100% RCA in full scale beams with different longitudinal

reinforcement ratios and reported 12% lower shear strength for the RAC

beams compared to the CC beams. Knaack & Kurama [32]

replaced both 50% and 100% of RCA (from 90 years old building) to cast

beams with cross section of 150mmx230mm. Their results showed small

reduction on shear strength of the RAC beams, but still existing codes

can be used to predict shear strength of the RAC beams.

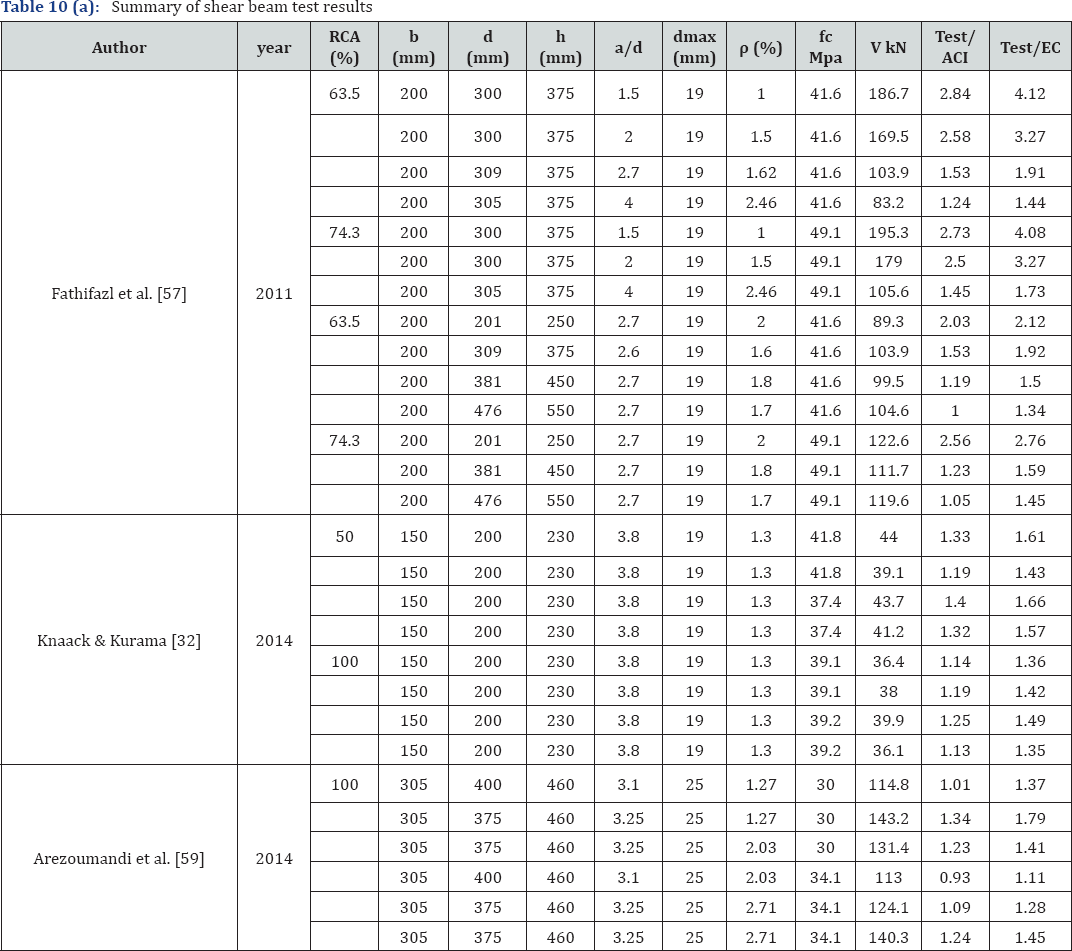

Table 10

summarizes details of shear beams test including width, b, height, h,

depth, d, shear span to depth, a/d, maximum aggregate size, dmax,

longitudinal reinforcement ratio, p, compressive strength, f'c, and

shear at failure, V. Furthermore, test results compared with shear

provisions of both ACI 318 [5] and EC 2 [7]. Table 10 (a) shows that both ACI 318 [5] and EC 2 [7]

shear provisions are conservative for more than 90% of data, even

though for the majority of tests the RAC beams showed lower shear

strength compared to the CC beams.

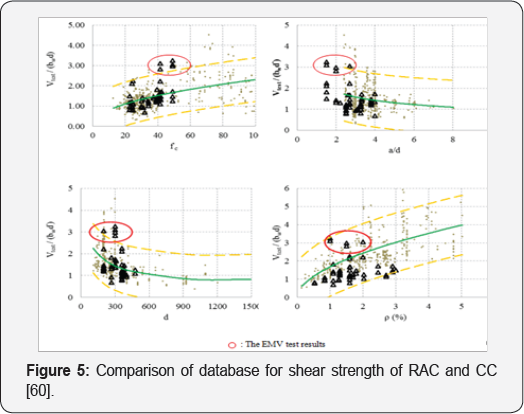

The four key parameters that affect concrete

contribution to shear strength include depth of member or size effect

(d), shear span to depth ratio (a/d), compressive strength of concrete

(f'c), and longitudinal reinforcement ratio (p). To evaluate the effect

of the aforementioned parameters on shear strength of the beams, the

results of RAC beams are compared with the wealth of shear test data

available in the literature for CC [60].

Figure 5

presents the shear stress versus f'c, p, d and a/d, respectively. Given

the significant scatter of the database of previous shear test results,

it is somewhat difficult to draw definitive conclusions on the current

test values. Nonetheless, visually, Figure 5 seems to indicate that the RAC test results fall within the lower portion of the data -except results of Fathifazl et al. [56]

- and follow the same general trend of the database. Furthermore,

statistical analysis (using regression analysis to draw the best fit and

95% confidence intervals) of the data indicates that the test results

fall within a 95% confidence interval of a nonlinear regression curve

fit of the database. This result indicates that the RAC beams shear

strength is lower than the shear strength of the CC.

Conclusion

The following conclusions can be drawn from literature review of mechanical properties and structural behavior of RAC specimens:

For more open access journals please visit our site: Juniper publishers

For more articles please click on Civil EngineeringResearch Journal

Comments

Post a Comment