Improving Railroad Safety with Risk Management-Juniper Publishers

Juniper Publishers -Journal of Civil Engineering

Perspective

Railroad safety and the prevention of derailments

remain a major concern of railroads worldwide. As railroads continue to

work to reduce derailments, a new generation of innovative risk

management techniques have been introduced to help railroads locate and

identify potential derailment sites as well as improve inspection

procedures and schedules [1-5].

These new techniques focus on the derailment causes them and develop

specific risk management tools that quantify and analyze the "risk" for

each key derailment or accident area. This has led to the development of

risk based tools to identify high risk locations in the track and

provide guidance for improved inspection and/or preventive maintenance

to reduce that level of risk.

For example, track caused derailments represent one

of the largest derailment categories both in US and worldwide. In the

US, it represents approximately 30% of all FRA reported derailments. The

major failure types identified under the track caused derailment

category are: broken rails, track geometry, turnouts and roadbed. In

each of these cause areas, research has resulted in new risk based tools

aimed at helping maintenance officers pinpoint potential derailment

location and take action to reduce the risk of a derailment. These

include risk based tools that look at:

i. Broken rail risk; to quantify the risk of

occurrence of a broken rail/broken rail derailment with a focus on

adjusting ultrasonic test schedules to reduce that risk [4,6].

ii. Risk based scheduling of track safety audit

inspections to optimize safety audit inspections, particularly on high

speed or high density track [5].

iii. Track geometry defect risk; to quantify the risk

of occurrence of a critical geometry defect (FRA violation) with a

focus on adjusting track geometry car test schedules to reduce that risk

[1,2].

iv. Inter-relation between track geometry defects and

the development of rail defects that increase the risk of a rail defect

developing at a given location [7,8].

v. Vehicle/track geometry risk; to identify and

prioritize locations with track geometry conditions that have a high

potential for vehicle/track geometry related derailments [9].

vi. Turnout condition; to quantify the condition of a switch (turnout) based on the potential for derailment [10].

vii. Track buckling risk; to identify and prioritize

locations of high potential buckling risk for follow up maintenance

action [11].

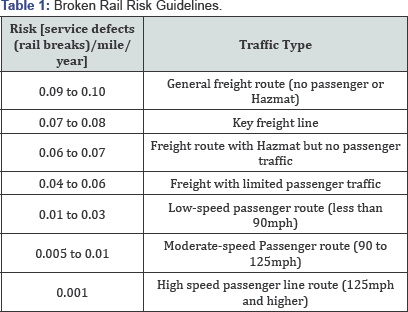

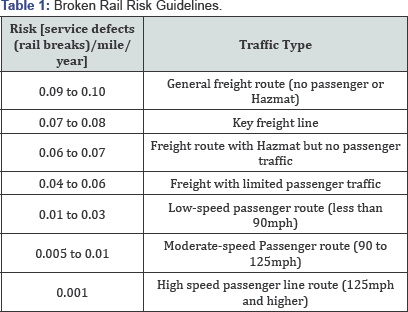

For example, broken rail risk management includes using service defect rate to determine allowable levels of risk (Table 1)

and determine ultrasonic rail test schedules. While service defects

represent only about 10% of all defects, they have a very strong

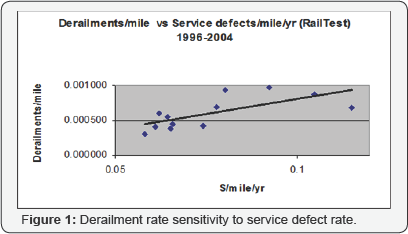

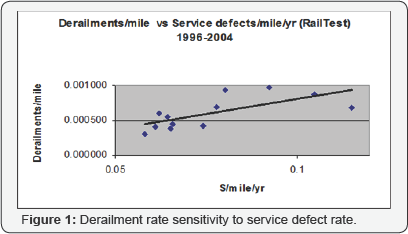

correlation to derailment occurrence, as shown in Figure 1.

Recent studies indicate that a broken rail derailment occurs

approximately every 133 service defects for a derailment per service

defect rate of 0.0075 [6].

As such they form the basis for a risk based scheduling methodology as

described in References 4 and 6. Actual implementation of this risk

based scheduling approach has shown a very well defined reduction in

derailments [6].

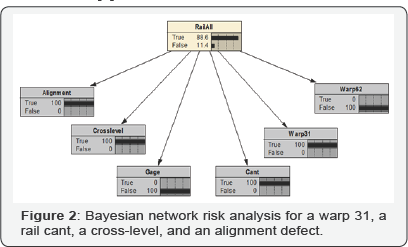

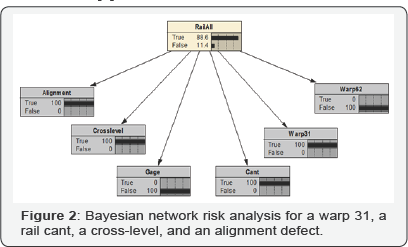

A further application of risk management calculates

the probability that a site with one or more geometry defects will

develop a rail defect [7,8]. This is illustrated in Figure 2

where a Bayesian model calculated an 88.6% probability of rail defect

developing at the site with multiple track geometry defects over a

period of five years.

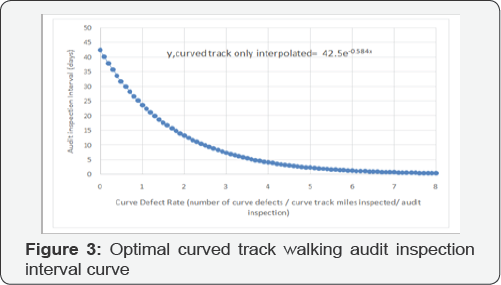

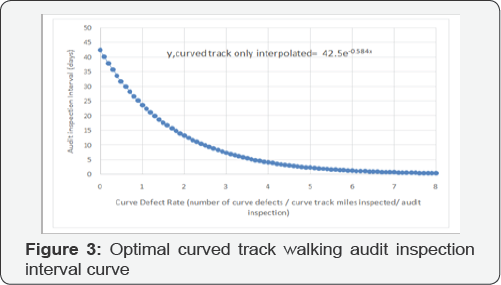

Yet another risk management application is for the

determination of when and where to conduct safety audit inspections.

This risk management approach process first establishes an acceptable

level of risk for having a safety violation in a given territory, and

then taking into account defect history and real-time track conditions,

schedules audit inspections based on those conditions. Figure 3 illustrates

the risk based audit inspection approach, where the frequency of audits

is directly related to the level of defects found in previous

inspections. The other referenced approaches follow the same principal

i. Defining a relationship between the risk sensitive parameters and safety as defined here by occurrence of derailments (Figure 1).

ii. Quantifying the relationship (Figure 2).

iii. Quantifying the level of risk acceptable under a range of operating conditions (Table 1).

iv. Developing a relationship between risk parameter and inspection/other action to reduce risk and improve safety (Figure 3).

As can be seen, a new generation of track safety

management tools has been developed to quantify and analyze the "risk"

associated with key track failure modes. These risk based assessment

tools have been shown to contribute directly to a reduction in track

failures through their ability to selectively identify high risk

locations and bring remedial action to bear on these identified

locations. The model classes presented here all rely on research that

has been developed over the last several decades, and are designed to be

used in large-scale applications, to identify potential failure sites

across an entire route or railway system.

The results have been clear and impressive. Use of

risk-based test scheduling techniques reduces the risk of derailments.

For example, in the case of broken rail derailments, use of risk based

assessment and rail test scheduling to determine optimum rail test

intervals, has resulted in a reduction in the rate of broken rails and

broken rail derailments by 30% or more on several major US railroads.

i. Broken rail risk; to quantify the risk of

occurrence of a broken rail/broken rail derailment with a focus on

adjusting ultrasonic test schedules to reduce that risk [4,6].

ii. Risk based scheduling of track safety audit

inspections to optimize safety audit inspections, particularly on high

speed or high density track [5].

iii. Track geometry defect risk; to quantify the risk

of occurrence of a critical geometry defect (FRA violation) with a

focus on adjusting track geometry car test schedules to reduce that risk

[1,2].

iv. Inter-relation between track geometry defects and

the development of rail defects that increase the risk of a rail defect

developing at a given location [7,8].

v. Vehicle/track geometry risk; to identify and

prioritize locations with track geometry conditions that have a high

potential for vehicle/track geometry related derailments [9].

vi. Turnout condition; to quantify the condition of a switch (turnout) based on the potential for derailment [10].

vii. Track buckling risk; to identify and prioritize

locations of high potential buckling risk for follow up maintenance

action [11].

Comments

Post a Comment